PUMPS AUSTRALIA PTY LTD

PUMPS AUSTRALIAPTY LTD

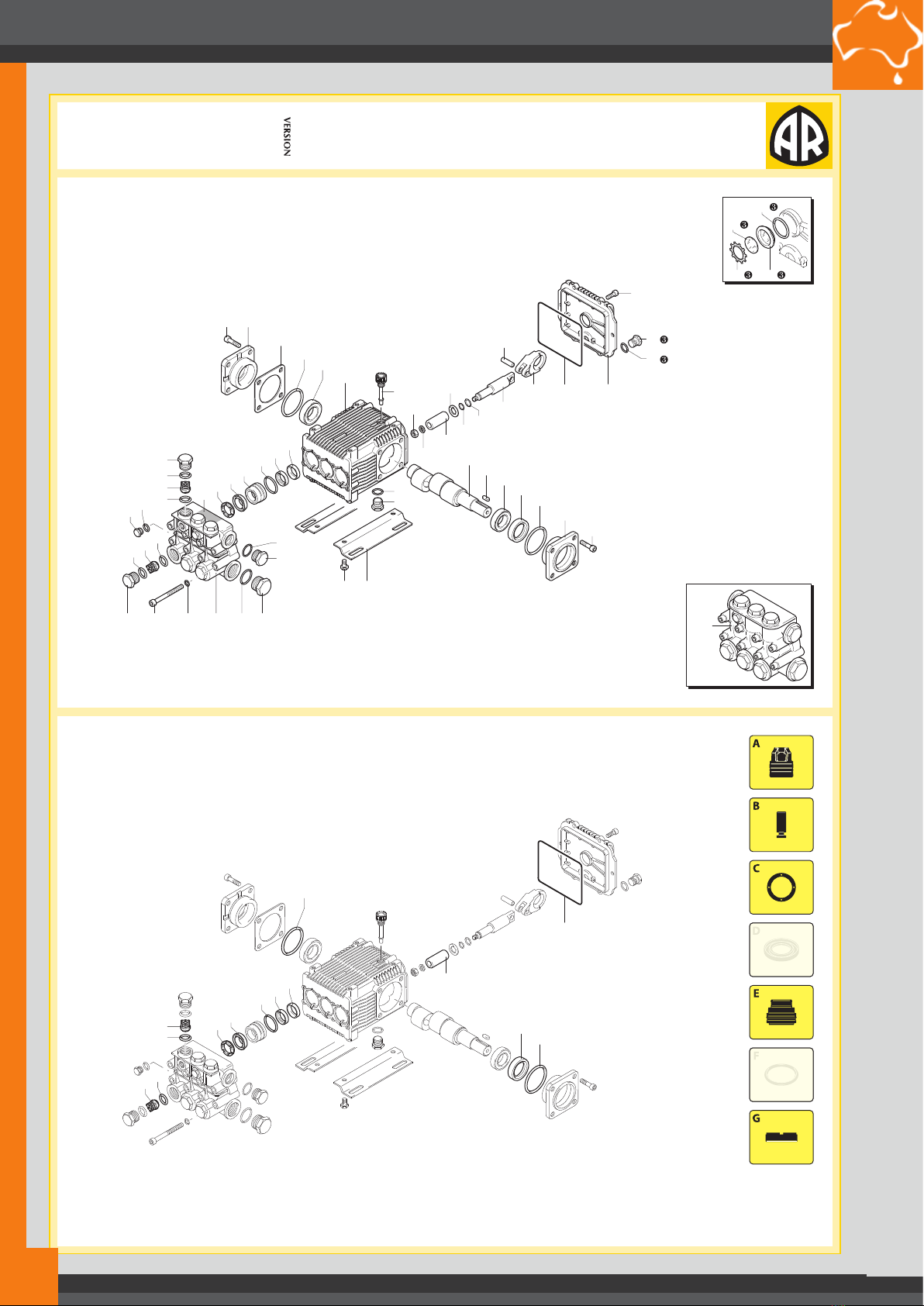

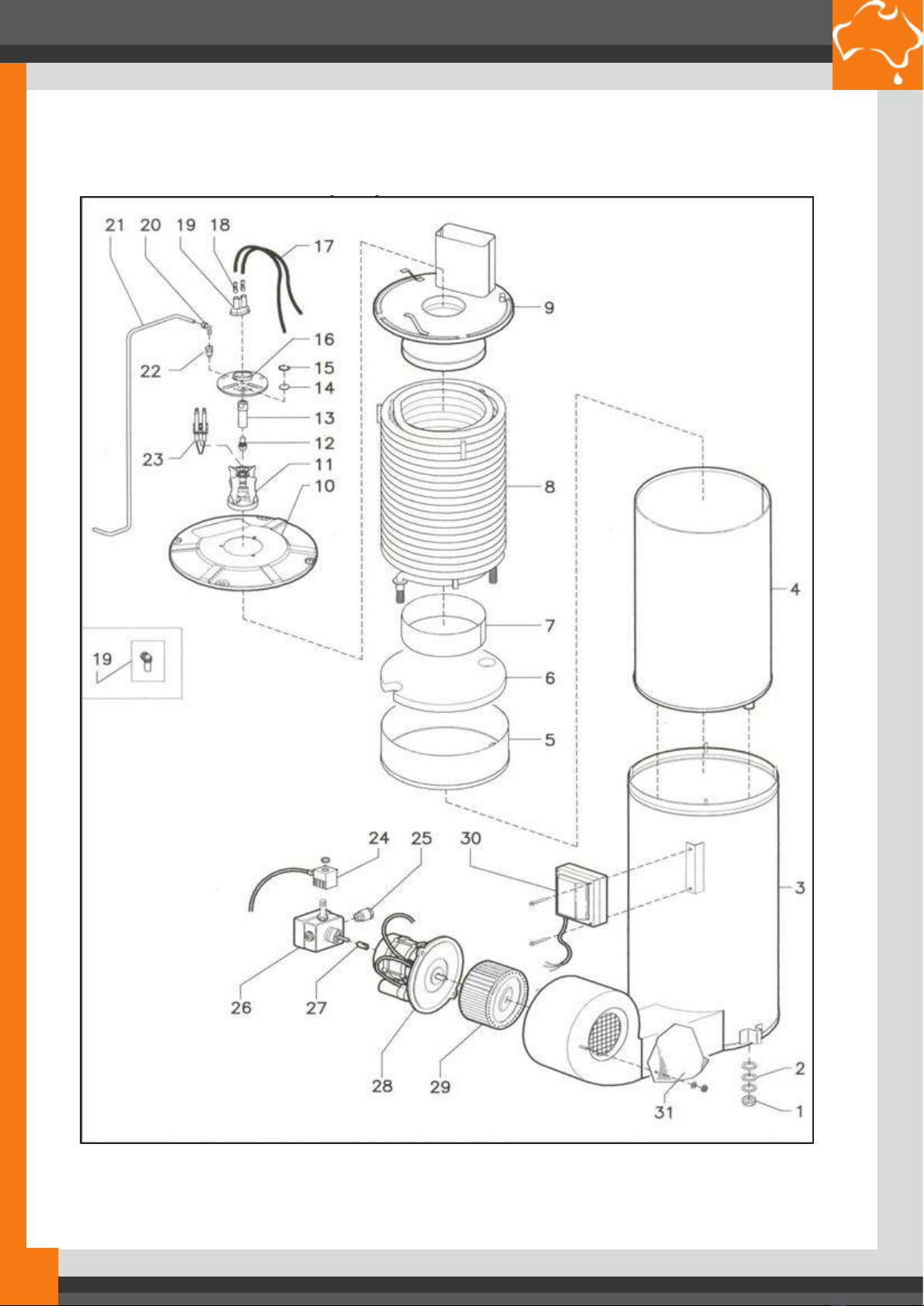

PARTS BREAKDOWN

97

SIMBOLOGIA - SYMBOLSKIT RICAMBI - PART KITS

228 Series

RK 1450 rpm N version ø 24 mm

11.14 (20630) 13.17 (20634) 15.15 (20637) 15. 20 (20897) (FC) 18.20 H (20643) 21.15 (20645) 18.16 H (FP)

11.20 H (20631) 13.20 H (20635) 15.20 H (20638) 15.28 H (20640) 18.28 H (21467) 21.20 H (21129)

11.25 H (20632) 14.16 (20636) 15.25 H (20639) 18.12 (20641) 21.10 (20644) 13.12 (FP)

PARTI SPECIALI IN VITON SPECIAL PARTS

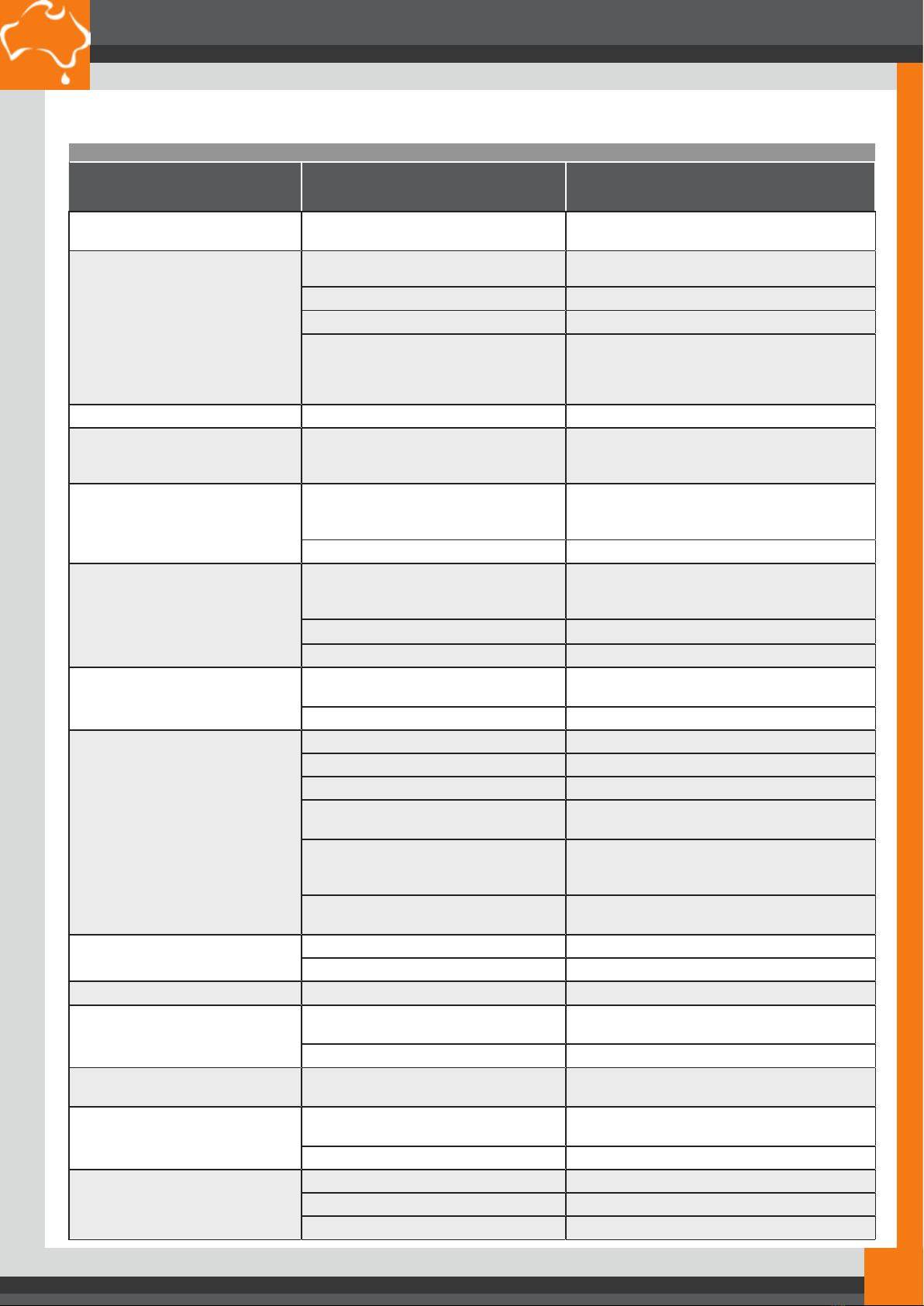

Cod. - Part n° Denominazione - Description Q.tà - Q.ty

2809 Tenute acqua/Water seals ø 18 1

2810 Tenute acqua/Water seals ø 20 1

2811 Tenute acqua/Water seals ø 22 1

A=KIT 2864

valvole

valves

pistoni

pistons

B=KIT 2757 ø 18

B=KIT 2758 ø 20

B=KIT 2759 ø 22

C=KIT 1855

tenute olio

oil seals

Pos. Q.ty Pos. Q.ty Pos. Q.ty

3 6 25 316 3

4 6 19 2

34 1

39 1

tenute acqua

water seals

E=KIT 1857 ø 18

E=KIT 1887 ø 20

E=KIT 1888 ø 22

anelli appoggio

support rings

G=KIT 1829 ø 18

G=KIT 1815 ø 20

G=KIT 1816 ø 22

Pos. Q.ty Pos. Q.ty

12 311 3

14 3

15 3

❍ Per / For

RK 11.14 cod. 20630

RK 11.20 H cod. 20631

RK 11.25 H ☞ cod. 20632

❒ Per / For

RK 13.12

RK 13.17 cod. 20634

RK 13.20 H cod.

20635

● Per / For

RK 14.16 cod. 20636

✪ Per / For

RK 15.15

cod. 20637

RK 15.20

cod. 20897

RK 15.20 H cod. 20638

RK 15.25 H ☞ cod. 20639

RK 15.28 H ☞ cod. 20640

✩ Per / For

RK 18.12 cod. 20641

RK 18.16 H

RK 18.20 H cod. 20643

RK 18.28 H ☞ cod. 21467

★ Per / For

RK 21.10

cod. 20644

RK 21.15 H

cod. 20645

RK 21.20 H

cod. 21129

C Tolleranza coppia di serraggio +0÷-10% / Tightening torque tolerance +0÷-10%

Avvitare con Loxeal 55-14 / Screw with Loxeal 55-14

(b) Montare anello tenuta con attrezzo cod. 2281010 / Fit the seal with tool code nr. 2281010

☞

OLTRE 250 bar - OVER 3600 psi

@ Posizionamento targa di identicazione / Identication plate positioning

Olio - Oil

Tipo / Type Quantità / Quantity

SAE 15W40 0,435 Kg

Pos. Cod. Denominazione Description Qt Note

1960160 Guarnizione OR Ø 17,86x2,62 O-ring 6

2

960090 Tappo Plug 6RK C=54Nm

960850 Tappo Plug 6

RK H ☞C=54Nm

1380740 Tappo Plug 6RK H C=54Nm

31389051 Valvola completa Complete valve 6

4 880830 Guarnizione OR Ø 15,54x2,62 O-ring 6

5

880581 Tappo 1/4" G Plug 2 RK C=15Nm

1380690 Tappo 1/4" G nickel Plug 2

RK H - H ☞ C=15Nm

6820510 Guarnizione OR Ø 10,82x1,78 O-ring 2

11

960110 Anello appoggio Ø 18 Ring 3❍ ❒ ● ✪

840300 Anello appoggio Ø 20 Ring 3✩

840320 Anello appoggio Ø 22 Ring 3★

12

1382740 Tenuta acqua Ø 18 Water seal 3❍ ❒ ● ✪

840290 Tenuta acqua Ø 20 Water seal 3✩

840330 Tenuta acqua Ø 22 Water seal 3★

13

1380090 Guida pistone Ø 18 Piston guide 3❍ ❒ ● ✪

1380150 Guida pistone Ø 20 Piston guide 3✩

1380160 Guida pistone Ø 22 Piston guide 3★

14 961240 Guarnizione OR Ø 31,47x1,78 O-ring 3

15

880330 Tenuta acqua Ø 18 Water seal 3❍ ❒ ● ✪

840280 Tenuta acqua Ø 20 Water seal 3✩

840340 Tenuta acqua Ø 22 Water seal 3★

16 1383130 Anello tenuta Ring 3

17 850370 Vite TCEI M8x16 Screw 8C=24,5Nm

18 1380050 Supporto

cuscinetto chiuso

Support 1

19 640030 Guarnizione OR Ø 59,99x2,62 O-ring 2

20 2280340 Cuscinetto Bearing 1

21 1382770 Corpo pompa Pump body 1

22 880130 Tappo Plug 1

23 962010 Dado Nut 3C=20Nm

24 962000 Rondella Washer 3

25

1380940 Pistone Ø 18 Piston 3❍ ❒ ● ✪

1380930 Pistone Ø 20 Piston 3✩

1382360 Pistone Ø 22 Piston 3★

26 1380950 Disco Plate 3

27 600180 Guarnizione OR Ø 7,66x1,78 O-ring 3

28 1380920 Pistone di guida Piston 3

29 1380060 Spina Pin 3

30

1383050 Biella alluminio Connecting-rod 3

1383020 Biella bronzo Connecting-rod 3

31 1080401 Anello antiestrusione Ring 3

32 1381850 Rondella Washer 8

Pos. Cod. Denominazione Description Qt Note

34 1780510 Guarnizione OR Ø 106x3 O-ring 1

35 1789010 Coperchio completo Cover 1

36 1343510 Vite TCEI M6x14 Screw 6C=10Nm

37

2280100 Albero marcato 5 Shaft 1❍

2280080 Albero marcato 3 Shaft 1❒

2280070 Albero marcato 2 Shaft 1●★

2280060 Albero marcato 1 Shaft 1✪ ✩

38 1380520 Linguetta Key 1

39 180340 Anello tenuta Ring 1(b)

40

1380120 Spessore 0,10 mm Shim 0.10 mm 1÷3

1380130 Spessore 0,19 mm Shim 0.19 mm 1÷3

1380530 Spessore 0,25 mm Shim 0.25 mm 1÷3

1382810 Spessore 0,05 mm Shim 0.05 mm 1÷3

41 1380040 Supporto

cuscinetto aperto

Support 1

42 740290 Guarnizione OR Ø 14x1,78 O-ring 3➌

43 1980740 Tappo 3/8" G ottone Plug 2➌ C=20Nm

44 1263130 Vite TE M8x12 Screw 4

Optional C=20Nm

45 1380141 Piede Foot 2Optional

46

1980740 Tappo 3/8" G ottone Plug 1RK C=25Nm

1981180 Tappo 3/8" G nickel Plug 1

RK H - H ☞ C=25Nm

47 180101 Guarnizione OR Ø 17,5x2 O-ring 1

48

820361 Tappo 1/2" G ottone Plug 1RK C= 40Nm

960870 Tappo 1/2" G nickel Plug 1

RK H - H ☞ C=40Nm

49

1381071 Testa Head 1Ø18 RK

1381070 Testa nikelata Head 1

Ø18 RK H - H ☞

1380020 Testa Head 1Ø20-22 RK

1380680 Testa nikelata Head 1 Ø20-22 RK H

50 820150 Vite TCEI M8x70 Screw 8C=24,5Nm

77 1383140 Cuscinetto Bearing 1

78

1389270

Premontaggio testa

Head assembly 1Ø18 RK

1389272

Premontaggio testa

Head assembly 1 Ø18 RK H

1389271

Premontaggio testa

Head assembly 1 Ø18 RK H ☞

1389208

Premontaggio testa

Head assembly 1Ø20 RK

1389212

Premontaggio testa

Head assembly 1 Ø20 RK H

1389216

Premontaggio testa

Head assembly 1Ø22 RK

1389220

Premontaggio testa

Head assembly 1 Ø22 RK H

86 1260250 Indicatore livello Level gauge 1 ➌

87 1260430 Anello Ring 1➌

88 1780690 Disco Plate 1➌

89 1140450 Guarnizione OR Ø 20,24x2,62 O-ring 1➌

➌Compreso nel cod. 1789010 / Part of part n° 1789010

MI 91423 (3056) (2322) (2990)DI_1388523 PAGE

9

PHONE: 1800 790 915

PUMPS AUSTRALIA PTY LTD

USER MANUAL