Table of Contents

1: Introduction………………………………………………………… 4

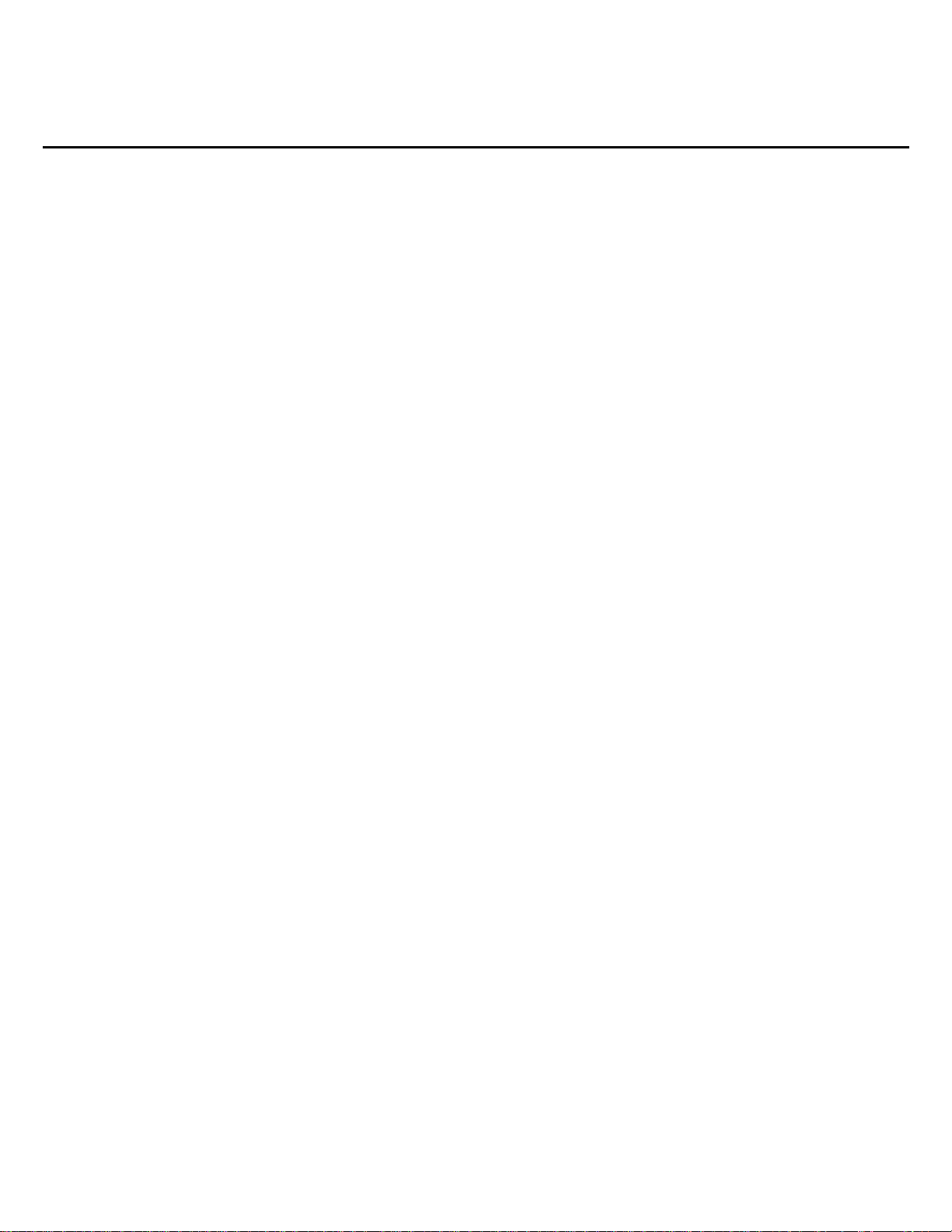

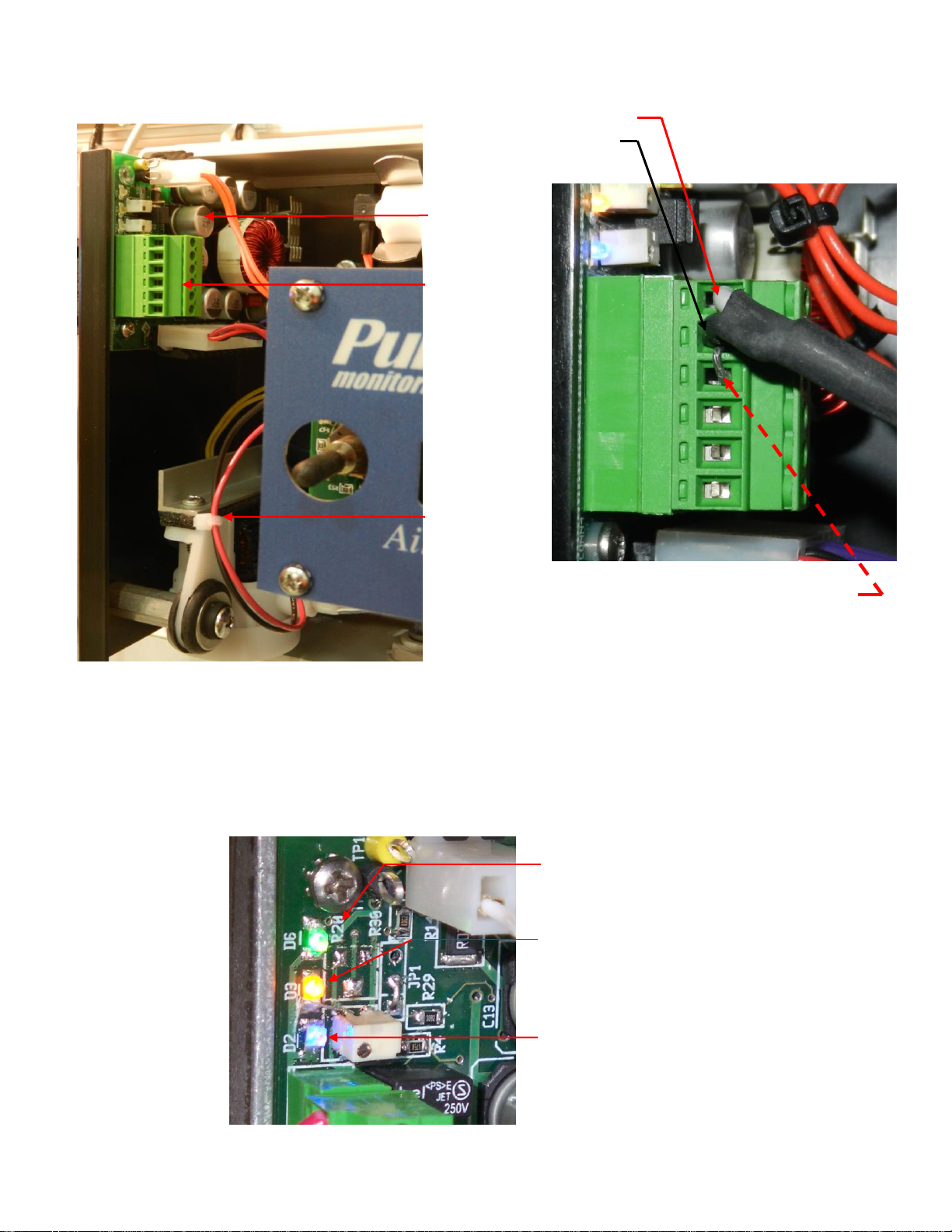

1.1 Component Identification……………………………………… 5

2: Specifications.................................................................................... 10

2.1 Performance Specifications........................................................ 10

2.2 Gas Detection System................................................................ 10

2.3 Signal Outputs............................................................................ 11

2.4 Electrical Requirements............................................................. 11

2.5 Physical Characteristics............................................................. 11

2.6 Air Check Carbonyl Sulfide Default Settings............................ 12

3: Installation........................................................................................ 13

3.1 Site Requirements...................................................................... 13

3.2 Mounting.................................................................................... 13

3.3 Sensor Installation...................................................................... 13

3.4 Wiring........................................................................................ 13

3.5 Initial Startup ............................................................................. 14

4: Air Check Carbonyl Sulfide Programming................................... 16

4.1 Control Panel Overview............................................................. 16

4.2 Joystick Operation ..................................................................... 16

4.3 Program Flow Chart................................................................... 17

4.4 Entering the Password................................................................ 18

4.5 Changing the User Password..................................................... 19

4.6 Entering the Menus.................................................................... 22

5: Maintenance & Calibration ............................................................ 33

5.1 Routine Maintenance Schedule.................................................. 33

5.2 Loss of Power Indication........................................................... 33

5.3 Sensor Cell Removal and Installation........................................ 34

5.4 System Calibration..................................................................... 36

6: Appendix........................................................................................... 40