5

www.purepowerequipment.com

SAFETY OVERVIEW

WARNING - WORK AREA

• Keep the work area clean and well lit. Cluttered benches and dark areas

increase the risks of accidents

• Do not operate the tool in explosive atmospheres, such as in the presence

of ammable liquids, gases, or dust. The tool creates a spark which may ignite

ammable liquids, gases or dust.

• Avoid unintentional misres. Always use caution to avoid accidentally ring.

Do not point at yourself or anyone else regardless if it contains fasteners or

not.

WARNING – PERSONAL SAFETY

• NEVER re a nail into another nail. Doing so can cause deection or broken

parts to become projectiles causing injury or damage.

• NEVER have your nger on the trigger unless you are about to re the nailer.

Having your nger on the trigger at any other time can result in a misre that

may cause injury or damage.

• NEVER point the nailer at yourself or anyone else regardless if you believe if it

is loaded with nails or staples or not.

• ALWAYS wear safety goggles for eye protection. Other protective equipment

such as hearing protection, steel toe boots, safety apparel, work gloves and

face shield are all recommended. Do not wear loose clothing or jewelry and

contain longer hair to avoid getting them caught in moving parts.

WARNING – TOOL USE AND CARE

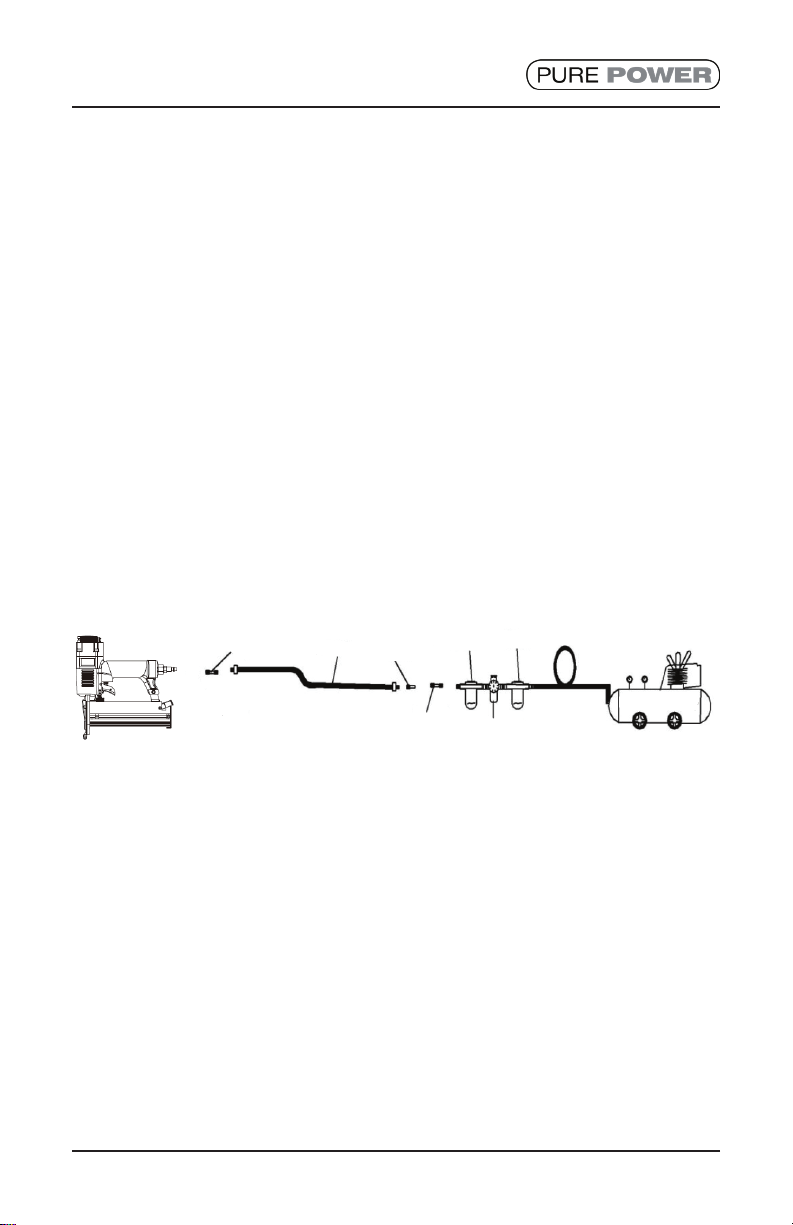

• ALWAYS make sure the hose can move freely. Hose entanglements or

obstructions may cause a sudden restriction of movement that can lead to a

dangerous misre.

• DO NOT wrap the hose around any parts of your body. This is an unsafe

practice.

• DO NOT carry or move the tool by dragging or pulling on the air hose that it is

attached to.

• ALWAYS assume the tool is loaded with nails or staples and may be able to

re at any time.

• NEVER attempt to repair or make modications to the tool. Do not tamper

with the safety features. This is a pressurized tool and may cause explosive

decompression of air if damaged.

• Wash your hands after handling. This product, the nails or staples, or the air

line may contain chemicals known to the State of California to cause cancer

and birth defences or other reproductive harm.

• NEVER spray ammable materials in the vicinity of the air compressor

because it may be an ignition source.

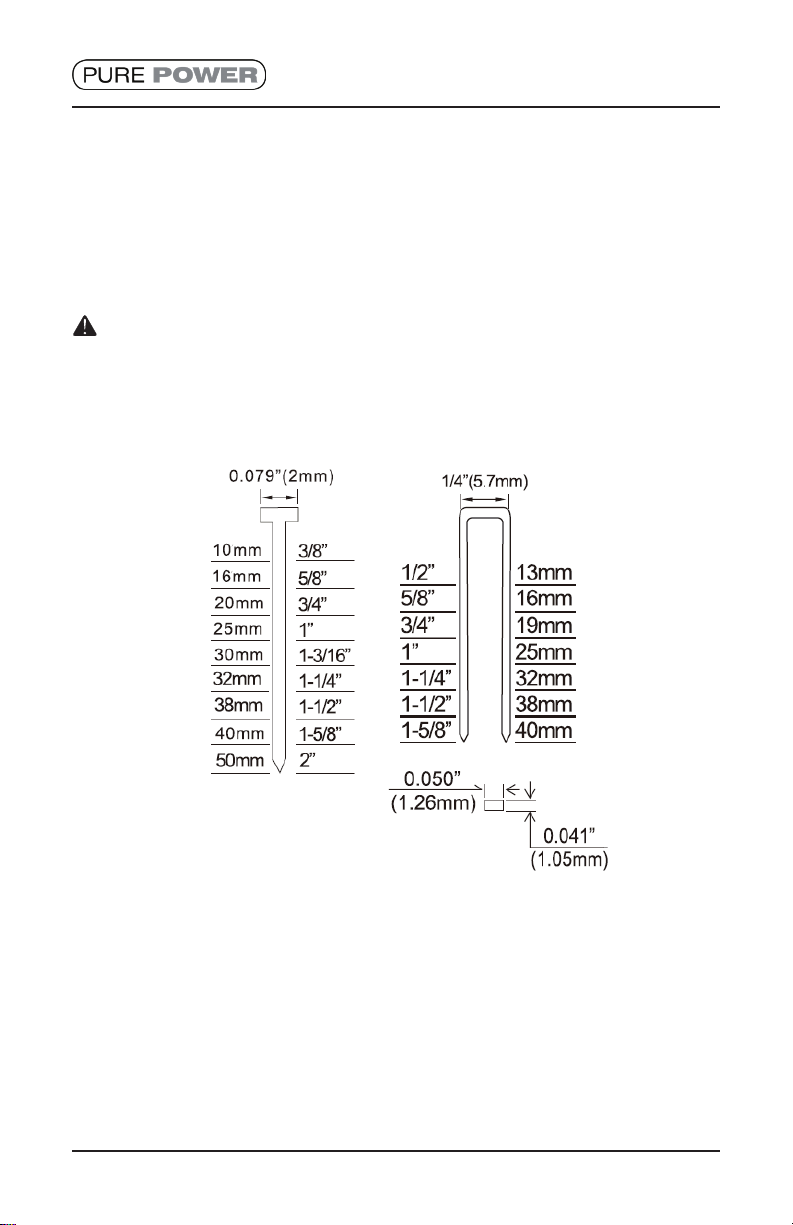

• ALWAYS use fasteners that a designed and intended for this tool. Never use

other types of fasteners and make the t.

• ALWAYS store the tool out of reach of children and other untrained people.

• ALWAYS check the tool before operation. Ensure the contact mechanism is

working properly. Do not use the tool if there is damage.

• DO NOT use the nailer if the trigger is not working properly.

• ALWAYS secure the work piece that is being nailed and ensure the proper

length of fastener is being used. If the fastener is too long, it can shoot out the

other side of the work piece causing injury.

• NEVER use this tool as a hammer or blunt instrument.

• NEVER use gasoline or other ammable liquids to clean the tool. This tool can

cause sparks when ring, which may ignite.

• NEVER use a check valve or similar device to trap air in the tool. Make sure

that when the tool is disconnected from the air source that it cannot re.