5. WARRANTY

END USER WARRANTY:

COMPANY AND/OR AUTHORISED INSTALLER:

(date and signature)

TECHNICAL ASSISTANCE LINE

S/O

P/N

S/N

* IF/PEU/PAM = IONFILTER/PURICOM EUROPE/

PURICOM AMÉRICA

The equipment has been installed and

is working in a satisfactory manner for

the client and for the record:

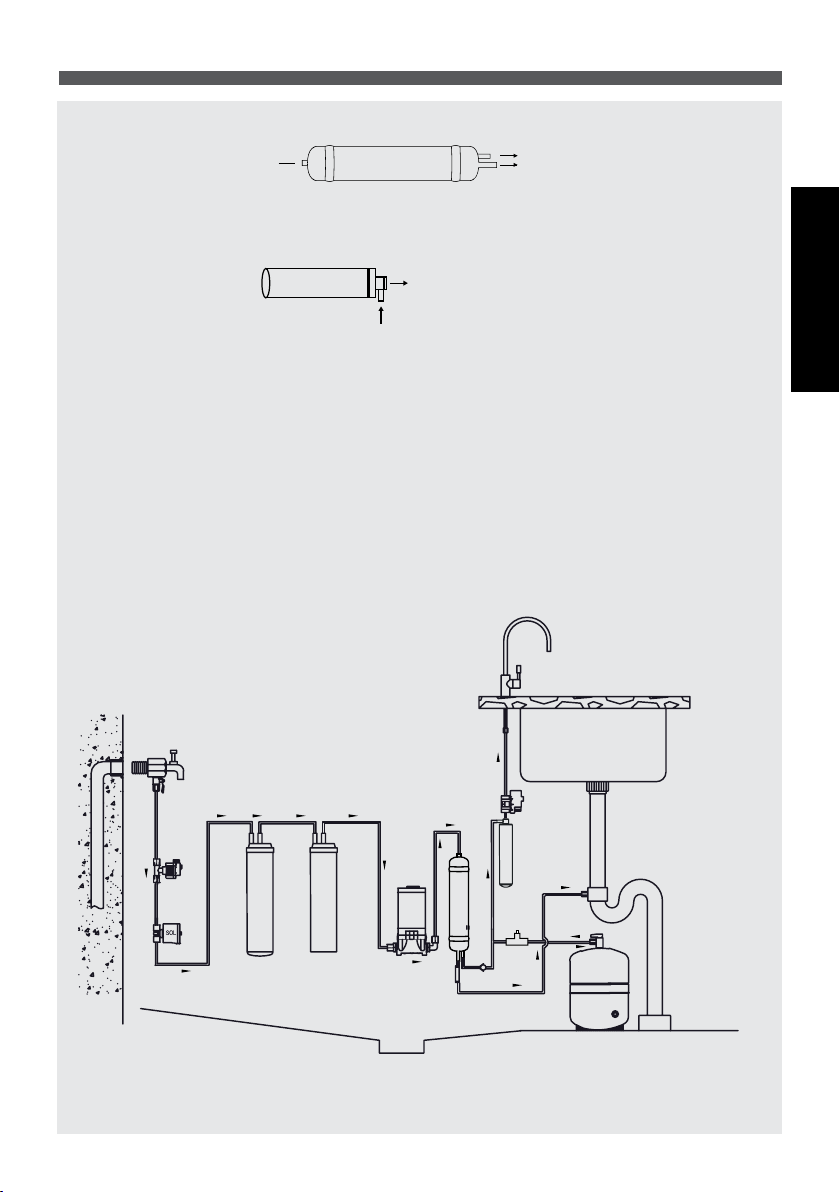

*RO equipment prior treatment:

*RO equipment entry hardness [ºF]:

*RO equipment entry TDS [ppm]:

*RO equipment entry pressure [bar]:

*TDS produced water (tap) [ppm]:

*Installation and initial operation

service result sheet

CORRECT.

OTHER INFORMATION:

*Ref. Maintenance contract

The maintenance contract IS ACCEPTED.

The maintenance contract is NOT

ACCEPTED.

NOTES FOR THE COMPANY/AUTHORISED TECHNICIAN/INSTALLER:

Information marked with an (*) should be filled in by the installation technician.

IDENTIFICATION OF THE SYSTEM:

The distributor guarantees this equipment for a period of two years against any fault

found, and in accordance with the provisions of RD (Royal Decree) 1/2007 of the 16th

of November (Amended text of the General Law for the Protection of Consumers and

Users). This guarantee encompasses reparaion and replacement of defective parts by

personnel authorised by the distributor or by the Official Technical Assistance Service

(SAT), either at the location of installation or at their respective workshops. Labour and

shipping costs incurred by said repairs are included in the guarantee.

IF/PEU/PAM will not be liable to honour the warranty in the event of parts, which are

subject to general wear and tear, lack of due maintenance, damage or other incidents

due to the consequence of misuse or inappropriate use in accordance with conditions,

and functional limits of said equipment as indicated by the manufacturer. Furthermore,

the warranty will be rendered invalid in the event of poor use or in the event of said

equipment being modified or repaired by personnel not authorised by the

distributor or by the official SAT. Replacement parts under warranty shall remain the

property of IF/PEU/PAM*. IF/PEU/PAM* shall be held responsible for any lack of

conformity of equipment in relation to its origin, identity or appropriateness of the

products, in accordance with equipment type and end use.Taking into account the

equipment’s characteristics, in order for the warranty to cover any lack of conformity,

the adherence to the installation and working technical conditions which appear in this

warranty is essential, as well as the submission of either a sales invoice or receipt.

Failure to comply with said conditions my invalidate this warranty, taking into account

the relevance of the equipment’s aim and conditions and

working limits.

The distributor guarantees that the installed equipment is appropriate for the improve-

ment of the quality of the water to be treated, in accordance with the equipment’s

characteristics and current legislation.

The installation personnel and/or distributor guarantees the correct installation and

initial operation of the equipment in accordance with the manufacturer’s instructions

and any current legislation, and will be responsible for any lack of conformity which

arises from any incorrect application, installation or initial operation of said equipment.

For any warranty claim the submission of the sales receipt is required. The 2-year

period is calculated from the date the equipment is purchased from the distributor.

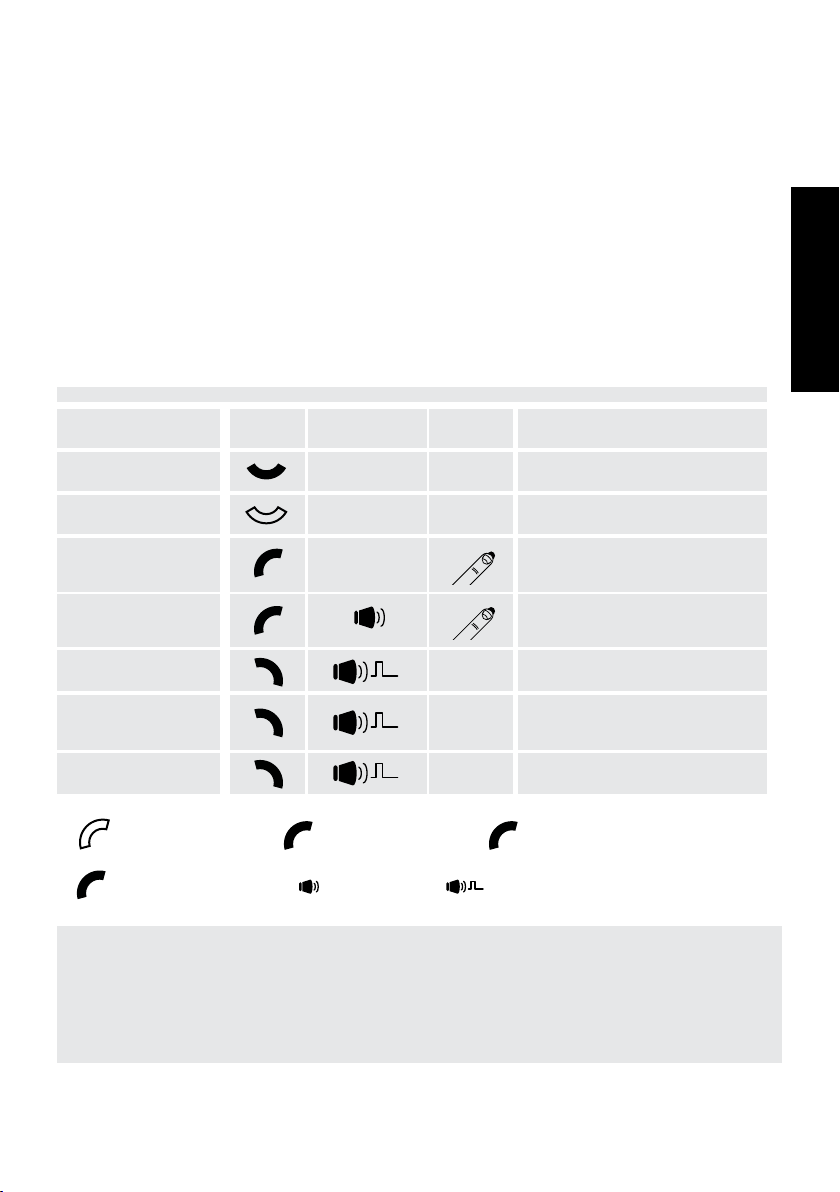

If during the warranty period the equipment encounters any issues please contact your

local distributor.

In the event of equipment installation, where the water to

be treated has a hardness in excess of 25ºF, IF/PEU/PAM*

shall not be held responsible for any equipment

breakdown, poor working or any associated consequences

caused by the water’s characteristics.

In the event of needing further information, to report

a breakdown or fault, please request either

maintenance or technical assistance. Please read

the sections relating to troubleshooting in this

manual and contact the distributor or retailer.

The equipment’s owners have been suitably and

clearly informed of the use and maintenance

required to ensure its correct working and of the

quality of water to be produced. To these effects a

maintenance contract is offered.