Pvelectronics Nixie Large Tube Clock Configuration guide

Other Pvelectronics Clock manuals

Pvelectronics

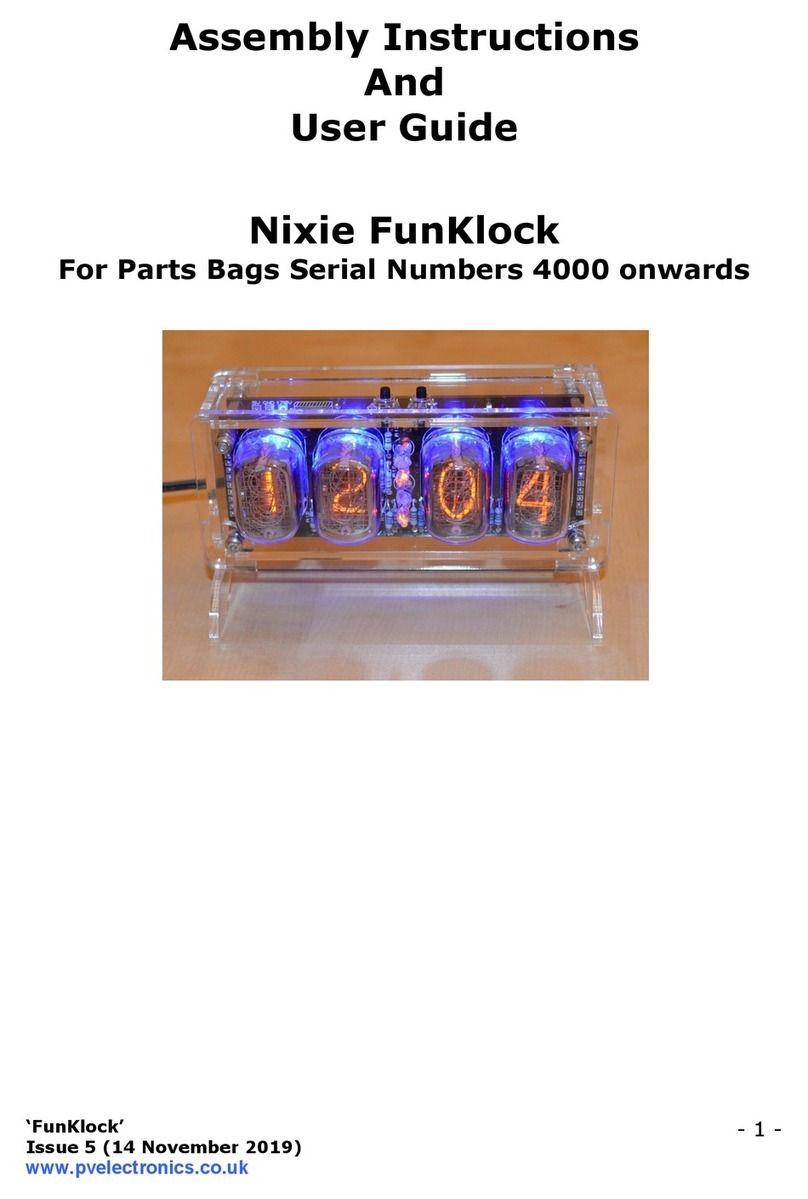

Pvelectronics Nixie FunKlock Configuration guide

Pvelectronics

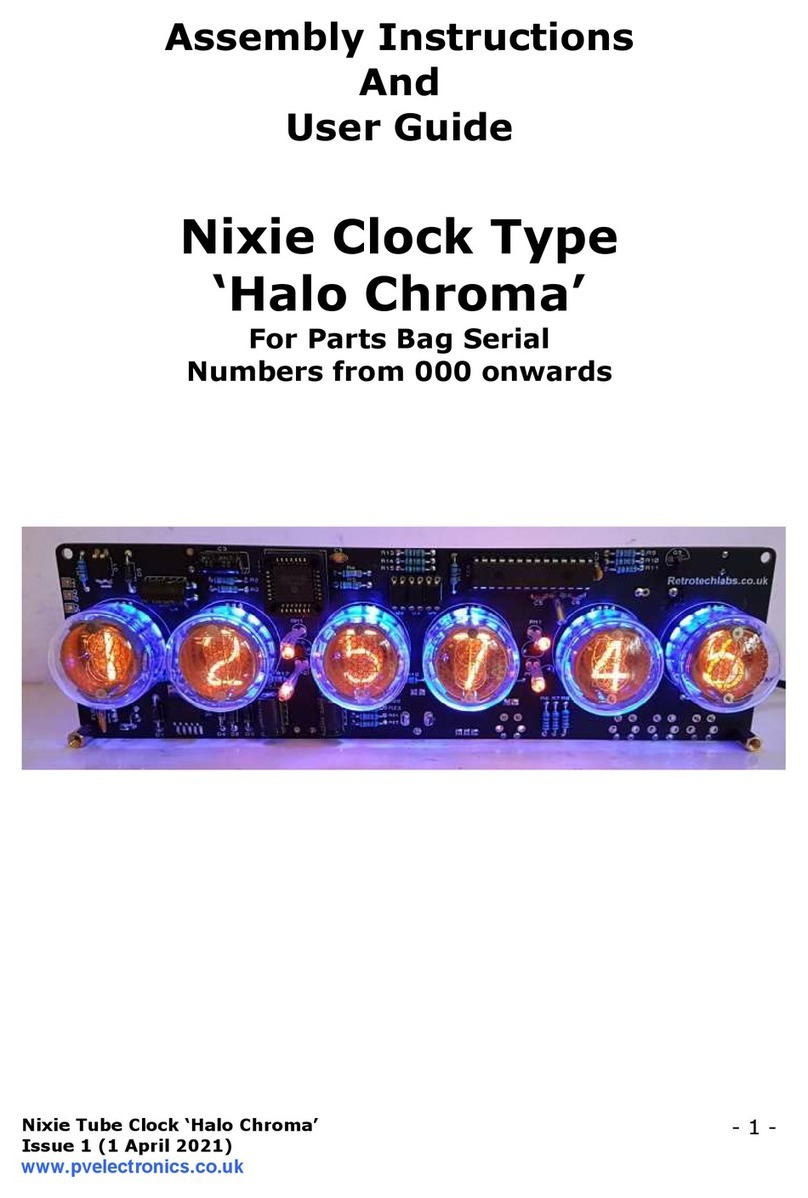

Pvelectronics Halo Chroma Configuration guide

Pvelectronics

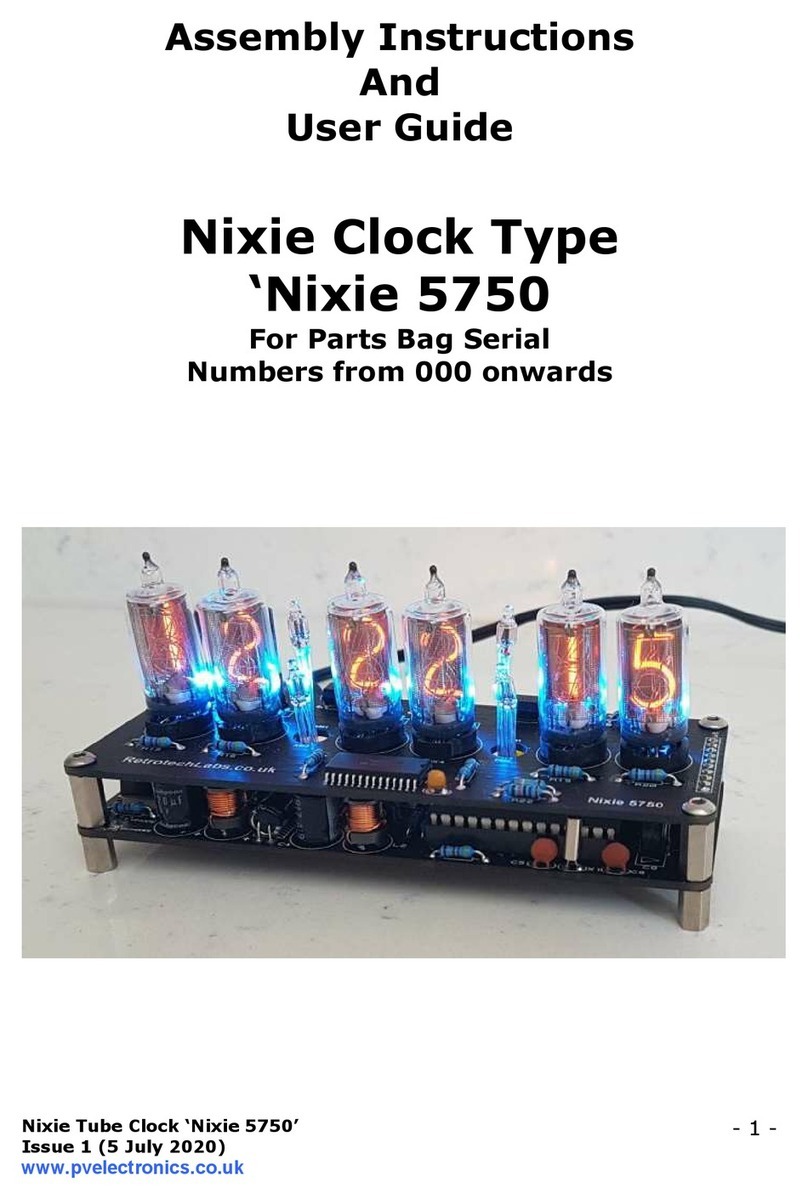

Pvelectronics Nixie 5750 Configuration guide

Pvelectronics

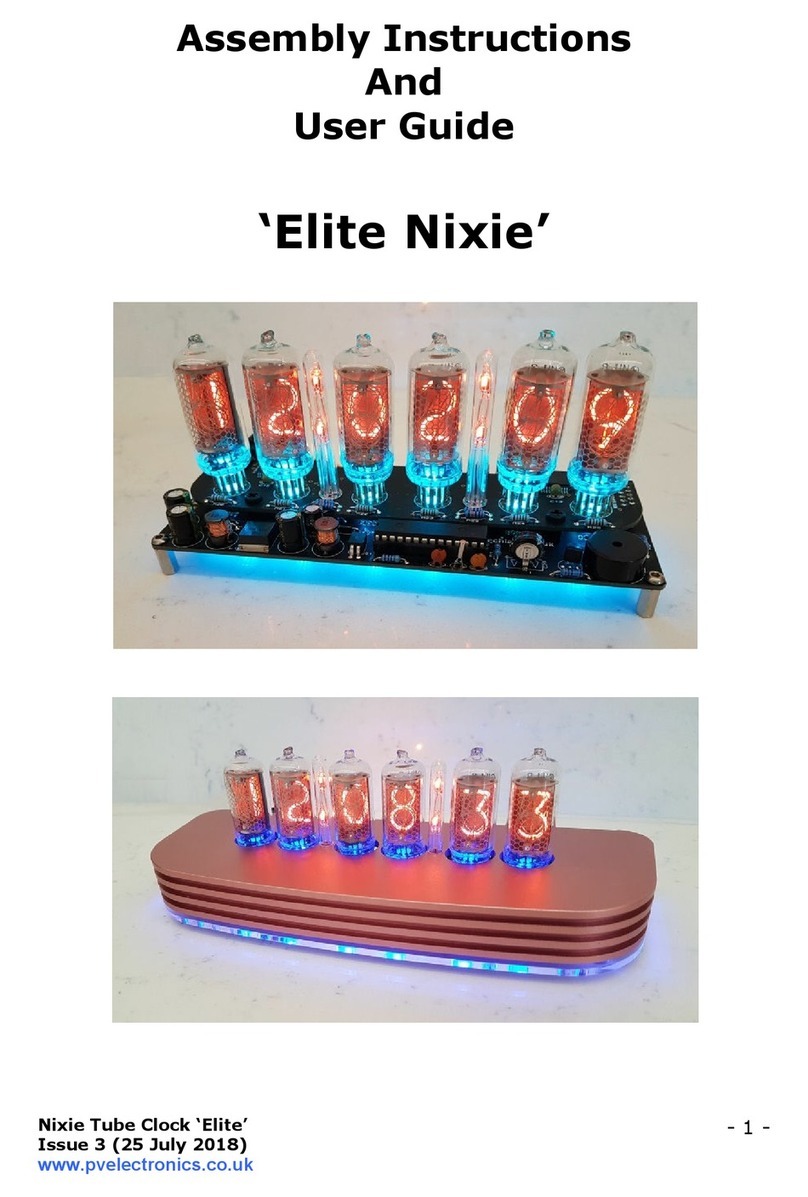

Pvelectronics Elite Nixie Configuration guide

Pvelectronics

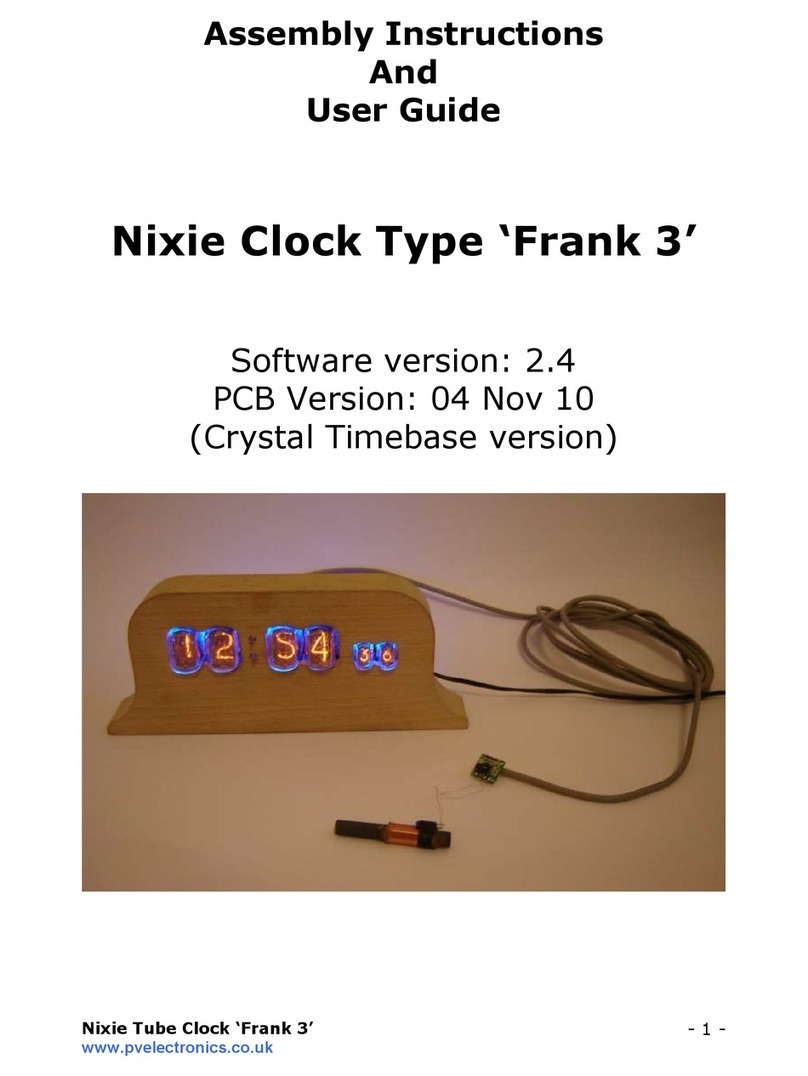

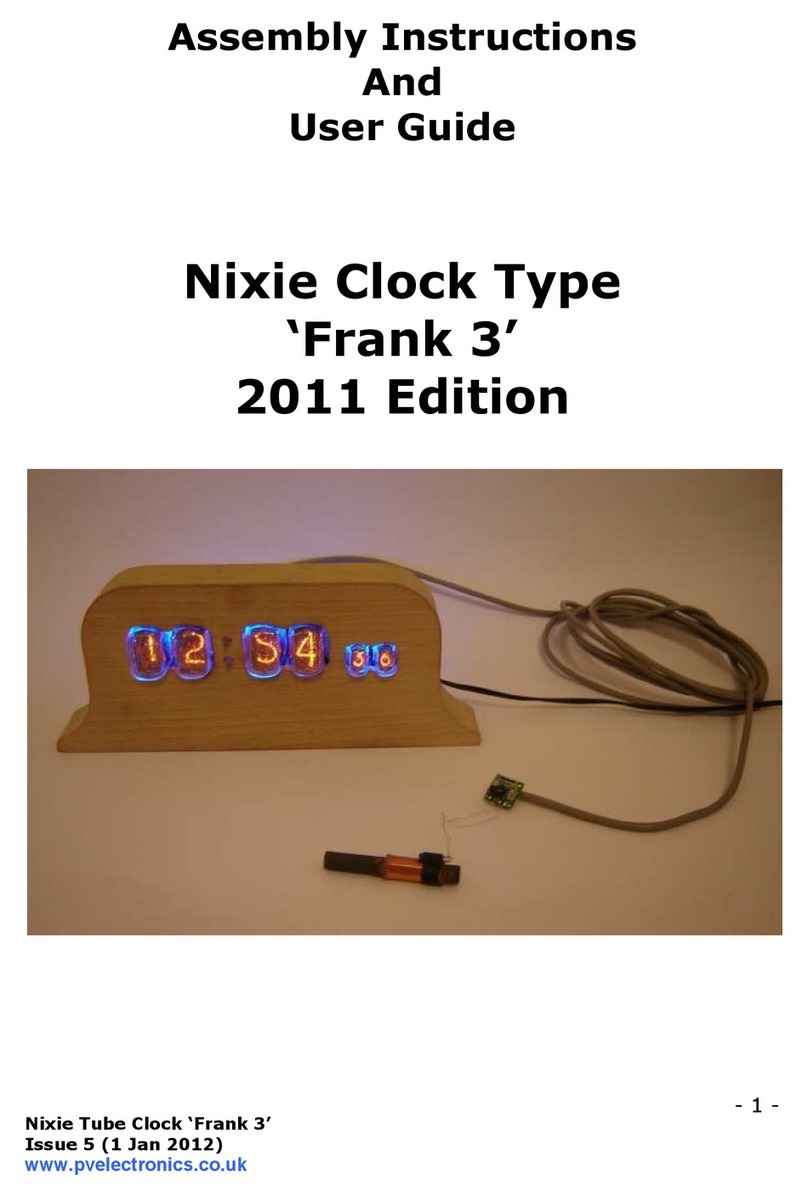

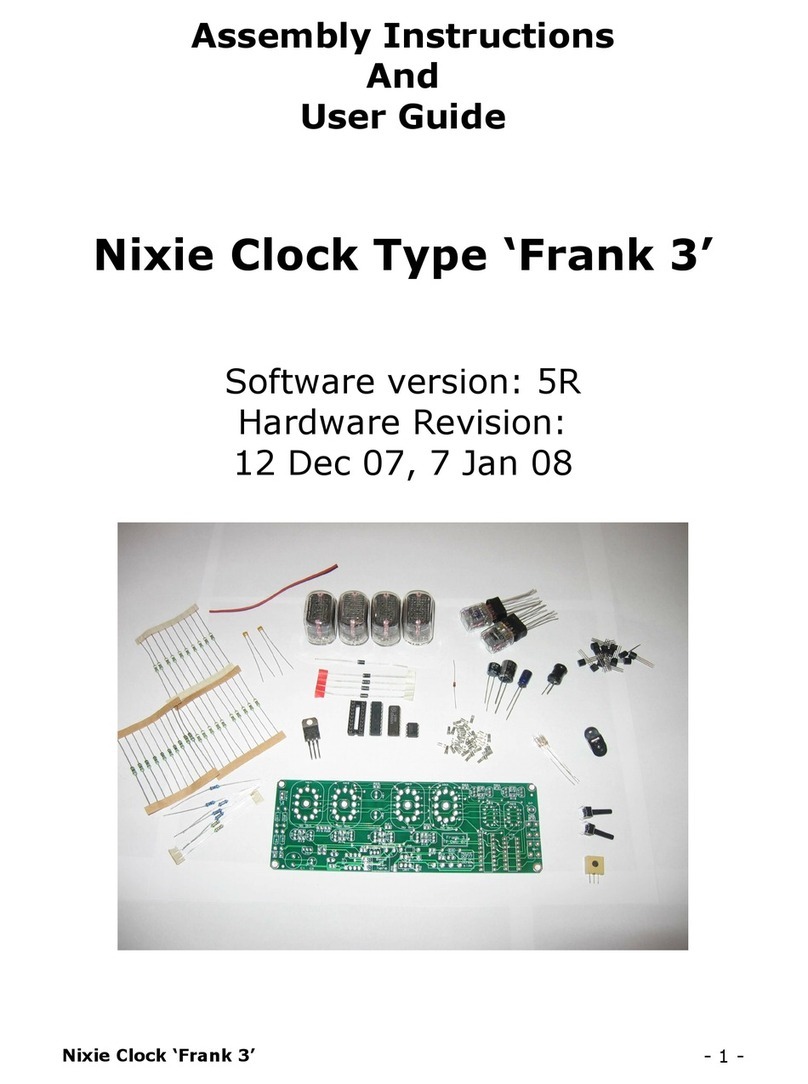

Pvelectronics Frank 3 Configuration guide

Pvelectronics

Pvelectronics Halo Clock Configuration guide

Pvelectronics

Pvelectronics Nixie Maestro Configuration guide

Pvelectronics

Pvelectronics Nixie QTC Plus Configuration guide

Pvelectronics

Pvelectronics Frank 3 Configuration guide

Pvelectronics

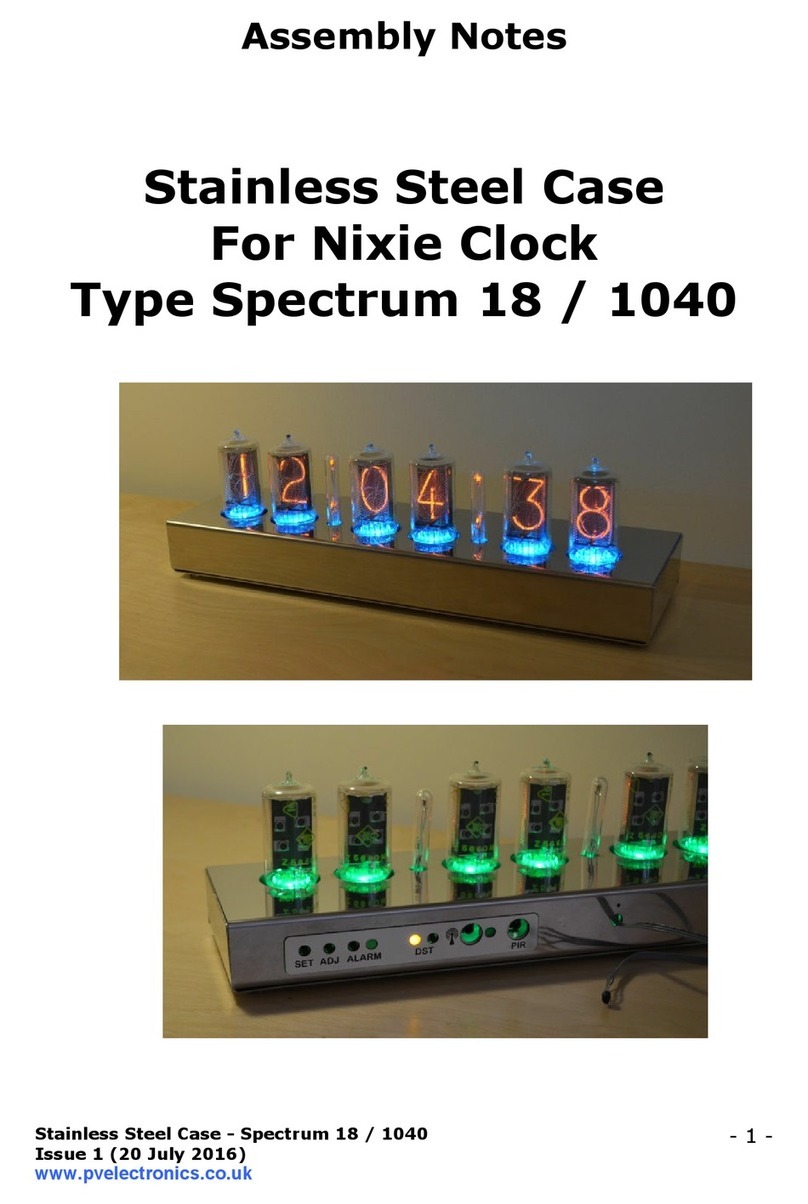

Pvelectronics Spectrum 1040 Quick start guide

Pvelectronics

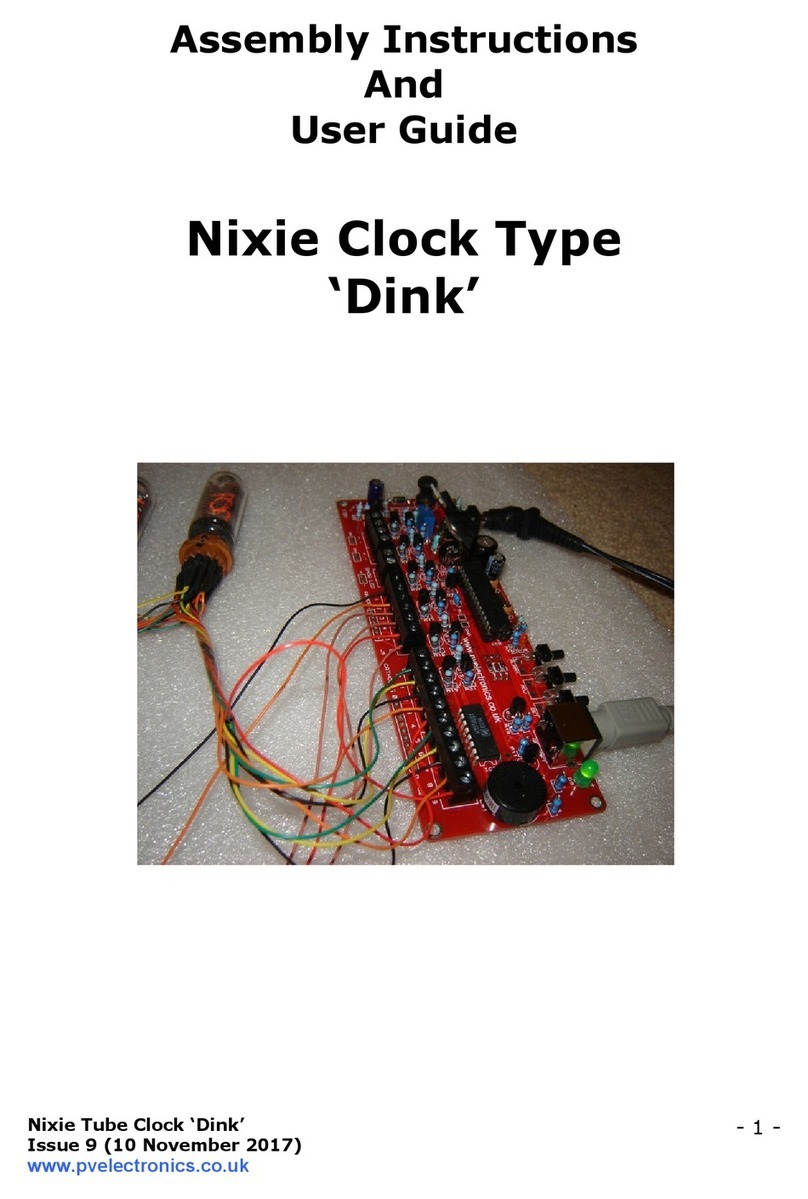

Pvelectronics Dink Configuration guide

Pvelectronics

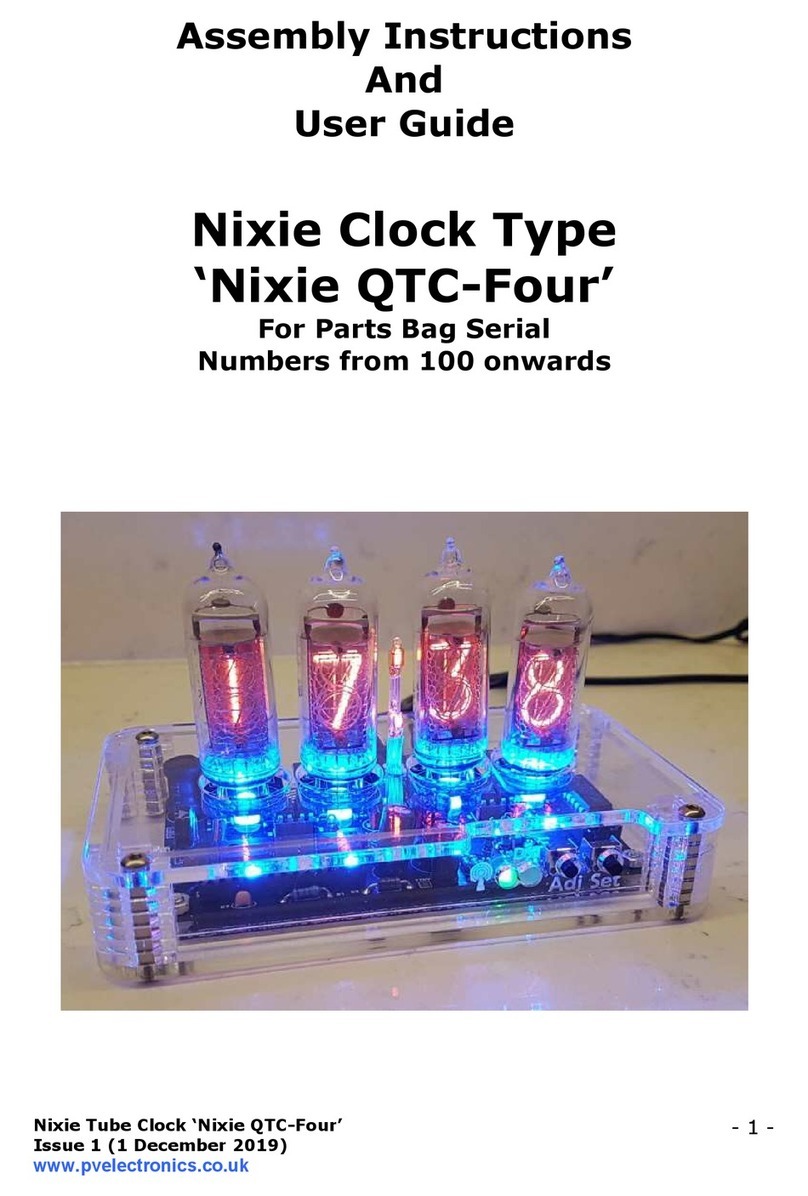

Pvelectronics Nixie QTC-Four Configuration guide

Pvelectronics

Pvelectronics Frank 3 Configuration guide

Pvelectronics

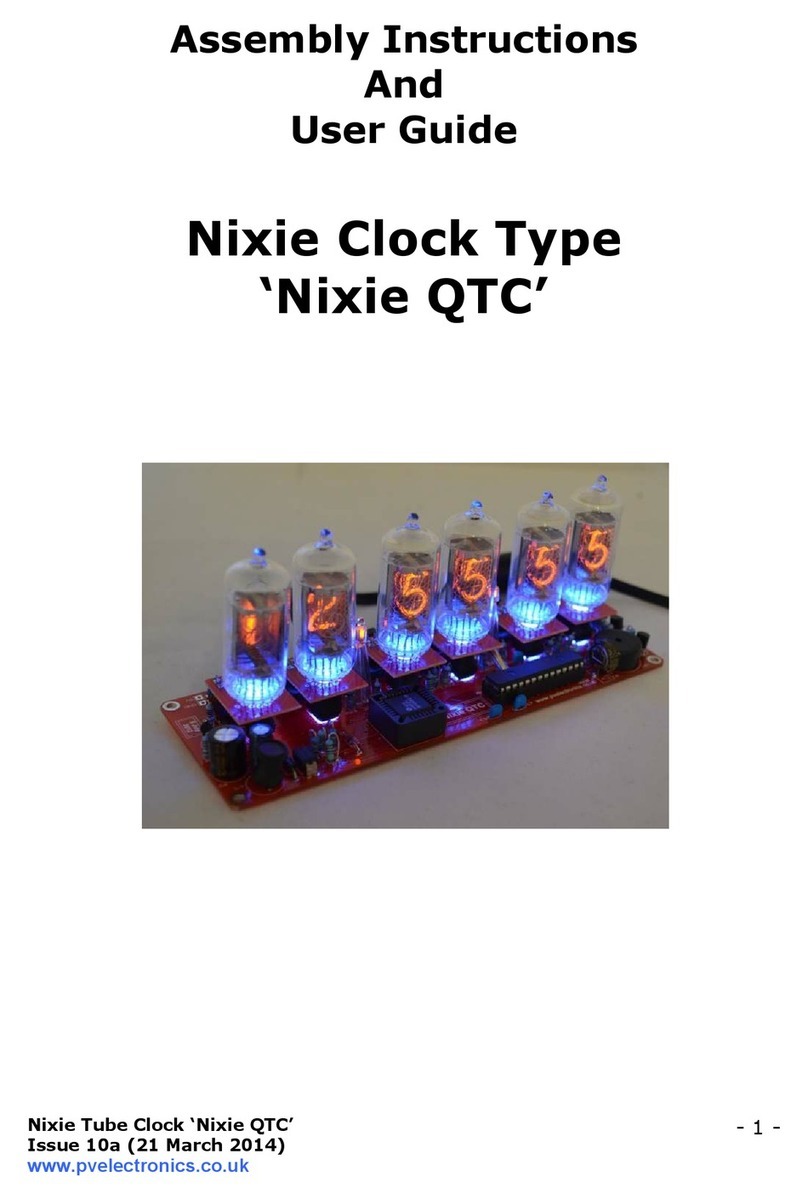

Pvelectronics Nixie QTC User manual

Pvelectronics

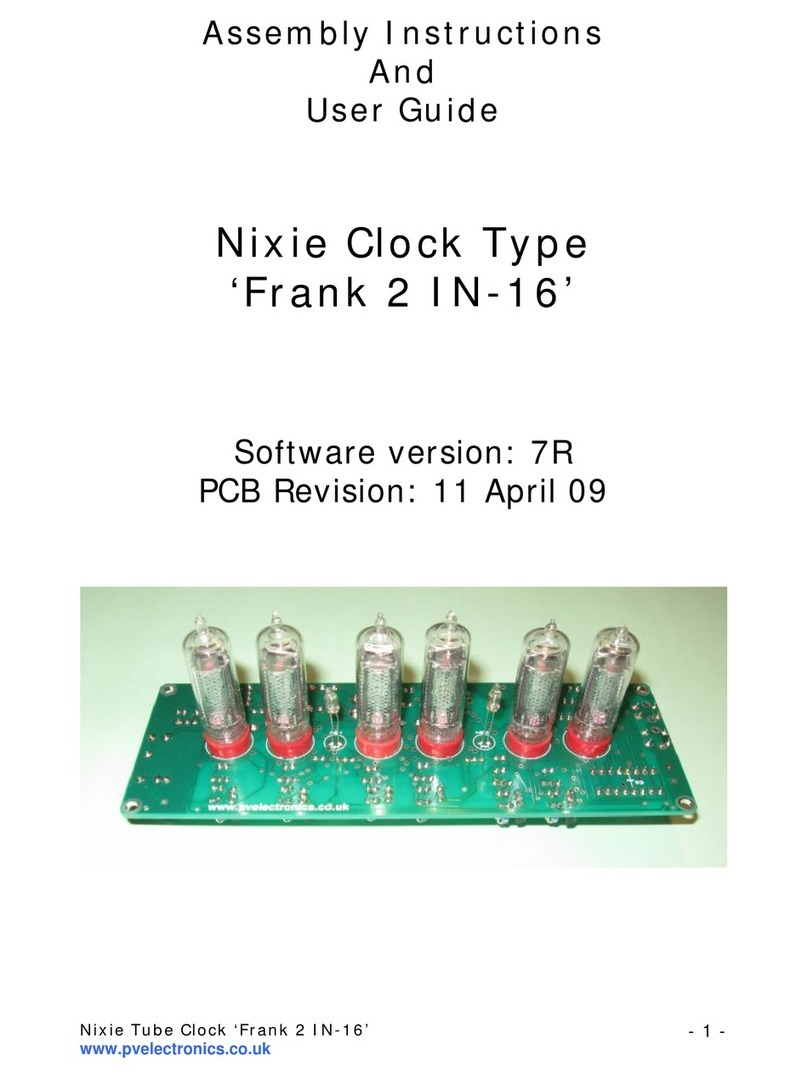

Pvelectronics Frank 2 IN-16 Configuration guide

Pvelectronics

Pvelectronics IN-8 Configuration guide

Pvelectronics

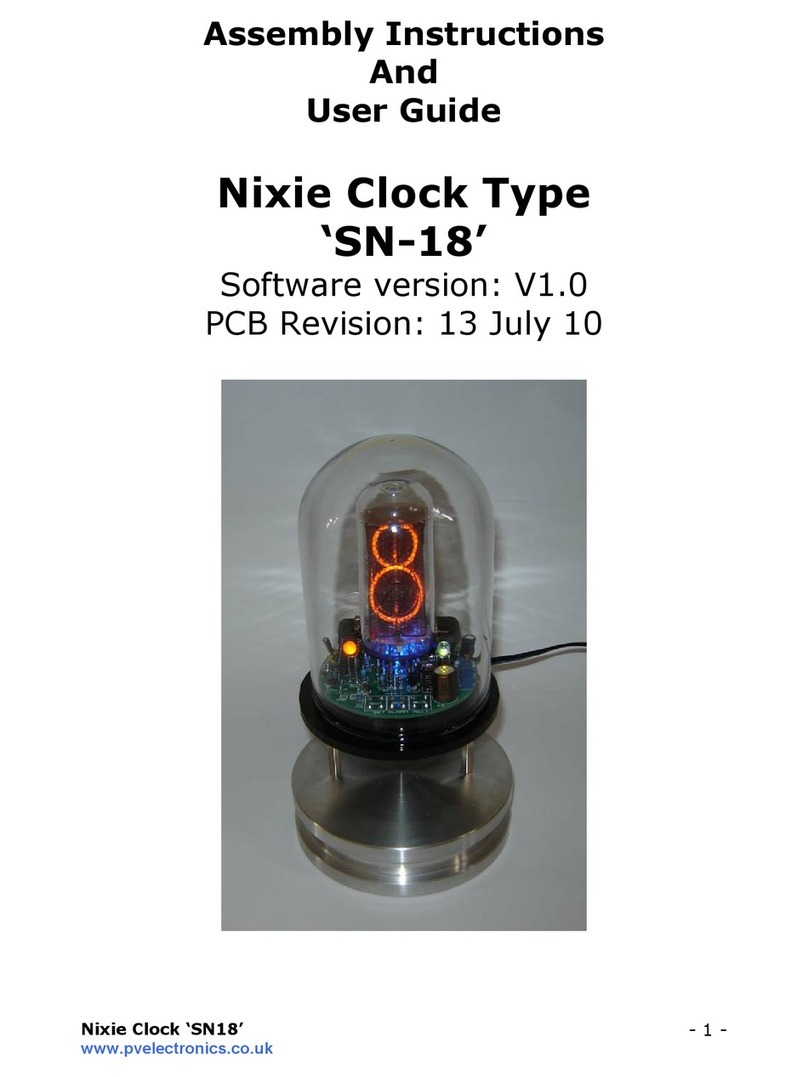

Pvelectronics SN-18 Configuration guide

Pvelectronics

Pvelectronics Spectrum 18 Configuration guide

Pvelectronics

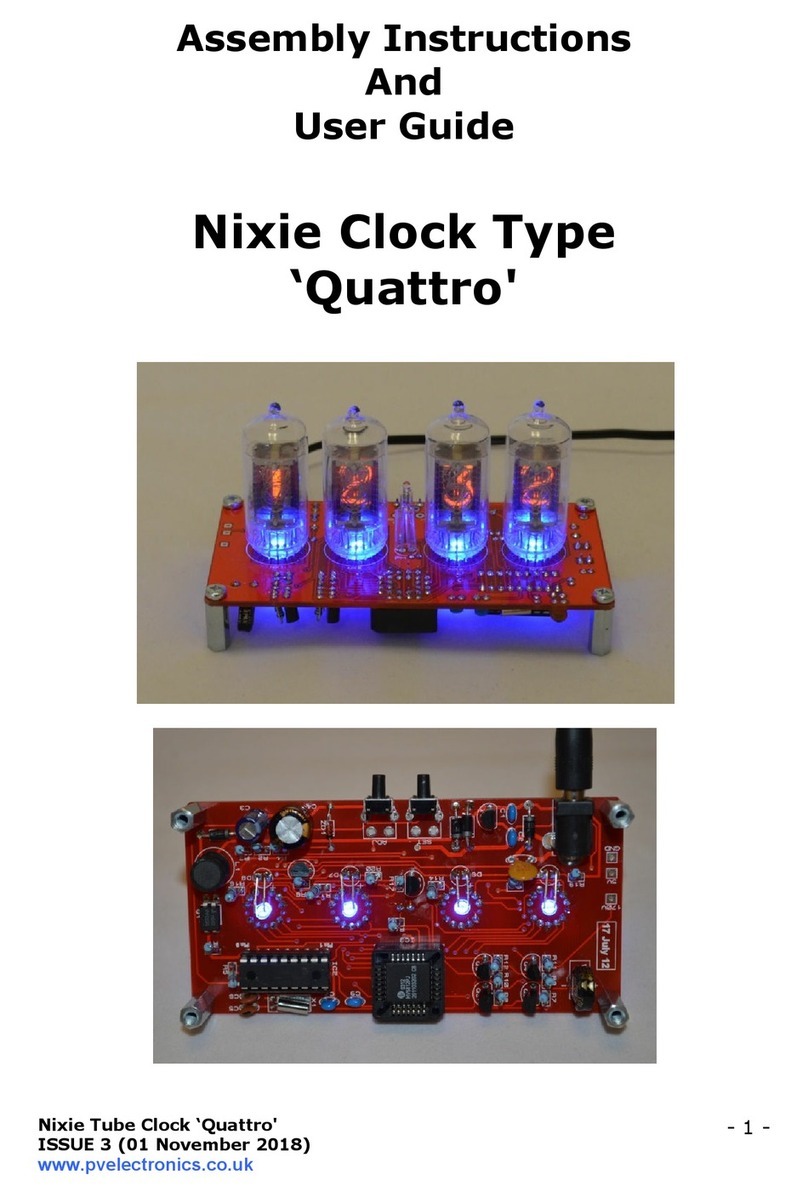

Pvelectronics Quattro Configuration guide

Pvelectronics

Pvelectronics Frank 3 Configuration guide