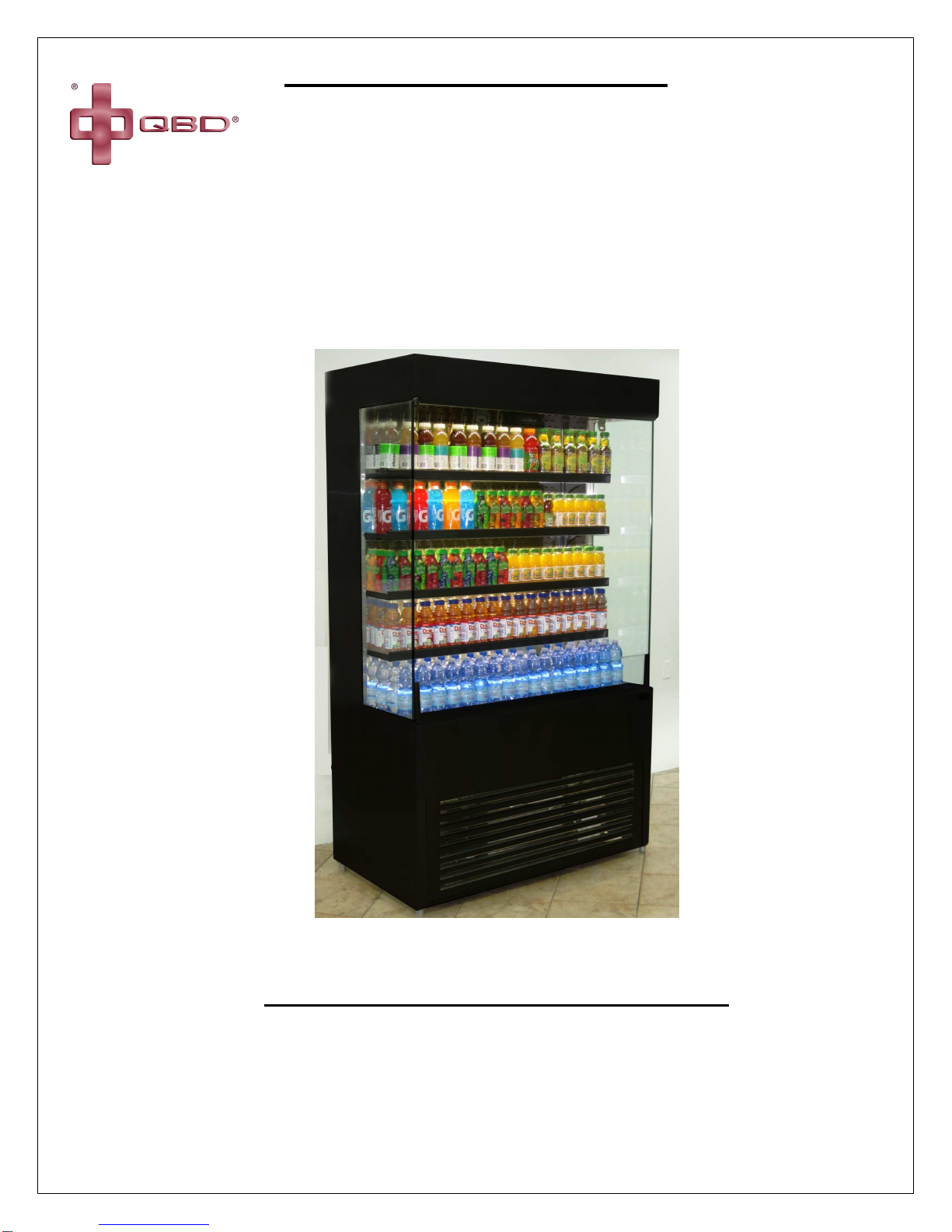

QBD COOLING SYSTEMS INC.

2

08 -2015 47-0480-192-N

2. Introd ction

Read this book carefully. It is intended to help you operate and maintain your new Refrigerated Display

case cooler properly. Always keep it handy.

Notes:

1. QBD does not cover loss or spoilage of products, loss of sales or consequential damages.

2. Always load pre-cooled product.

3. To ensure effective cooler performance, regular maintenance of the following is required:1)

Condenser, 2) Drain line, 3) Cleaning of Evaporator & Condenser Drip Tray.

For support please call:

anager, Customer Service,

QBD Cooling Systems Inc.

31 Bramsteele Road,

Brampton, Ontario,

Canada L6W 3K6

Tel.

Fax.

Web:

Email:

1(905) 459 0709

1(800) 663 3005

1(905) 459 1478

www.qbd.com

service@qbd.com

If you received a damaged display case:

Immediately contact the carrier that delivered you8 the cooler for all your claims.

All goods are shipped at the customer’s risk. Return of goods to the factory must have the authorized

approval of QBD. No returns will be accepted after 10 days. Any shortage claims must be made within 5

days of receiving the goods.

How to unpack your cooler:

For maximum protection, it is recommended that none of the packaging materials be removed before

the cooler has reached its final operation locations. First remove all the outer packing material from the

cooler. Now dismantle the skid below the base of the cooler by tilting the cooler to one side (right). Use

a wrench to remove the skid bolts-legs OR use a slot screwdriver and hammer to split and remove the

skid board. Repeat the same operation by tilting the cooler to its opposite (left) side.

Have the wall outlet and circuit checked by a qualified electrician to make sure that the outlet is properly

grounded and circuit breaker is in place as cooler manufacturer recommendation and/ or as per local,

regional or national standard.