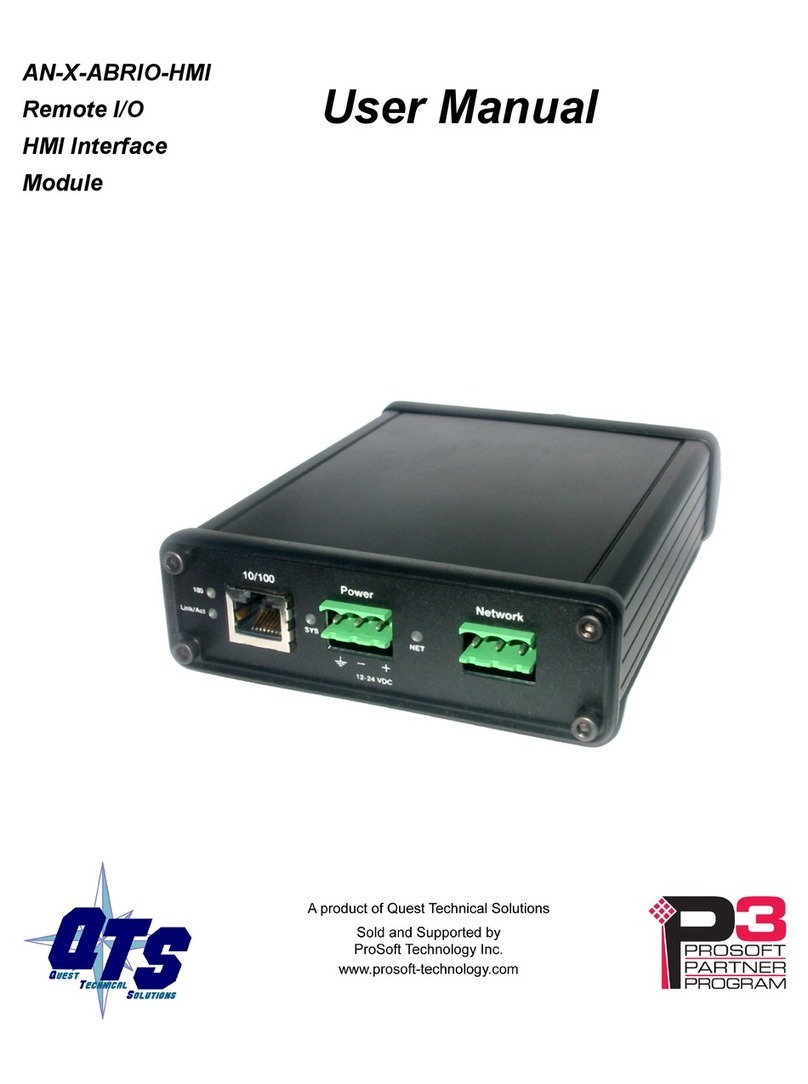

AN-X4-AB-DHRIO for Remote I/O HMI

The AN-X4-ABRIO-HMI communications module is used to connect HMI, SCADA, or MES

systems to data on an Allen-Bradley Remote I/O network. Typical applications include replacing

obsolete HMIs that have built-in Remote I/O cards with newer HMI terminals that connect to an

EtherNet/IP network such as a Panelview.

For applications where multiple HMI terminals exist on a single Remote I/O network, a single AN-X

gateway can be used to provide data to these HMI terminals.

Remote I/O network features include:

•emulates up to 63 racks, with rack numbers from 0 to 76 octal, in any combination of

partial racks

•monitors other racks on the remote I/O network

•supports all remote I/O baud rates

•supports block transfer reads and writes at all possible locations on these racks

Ethernet IP devices access data on the AN-X as PLC-5 input (I), output (O), status (S), integer (N),

binary (B) and floating point (F) files.

The AN-X4-ABRIO-HMI module has a web interface for configuration, for monitoring data, logs and

diagnostic counters, and for performing other administrative functions. You can communicate with

the module using any standard web browser.

The module firmware can be updated over Ethernet using the web interface. Refer to page 40 for

details.

A jabber inhibit timer is implemented in the module’s hardware. If the network transmitter is on

longer than 150% of the longest network frame time, the transmitter is forced off and the module is

placed into a safe fatal failure state.

You can obtain the latest firmware from qtsusa.com/dist/AN-X4_Dist/ along with some quick start

instructions.