Contents

Contents ii www.qualitrolcorp.com

13. Gen2 With Transmitter........................................................................ 18

13.1. Technical Data .............................................................................................18

13.2. Installation Instructions ..............................................................................18

Figures

Figure 1 – Switch Setting Scale .........................................................................................2

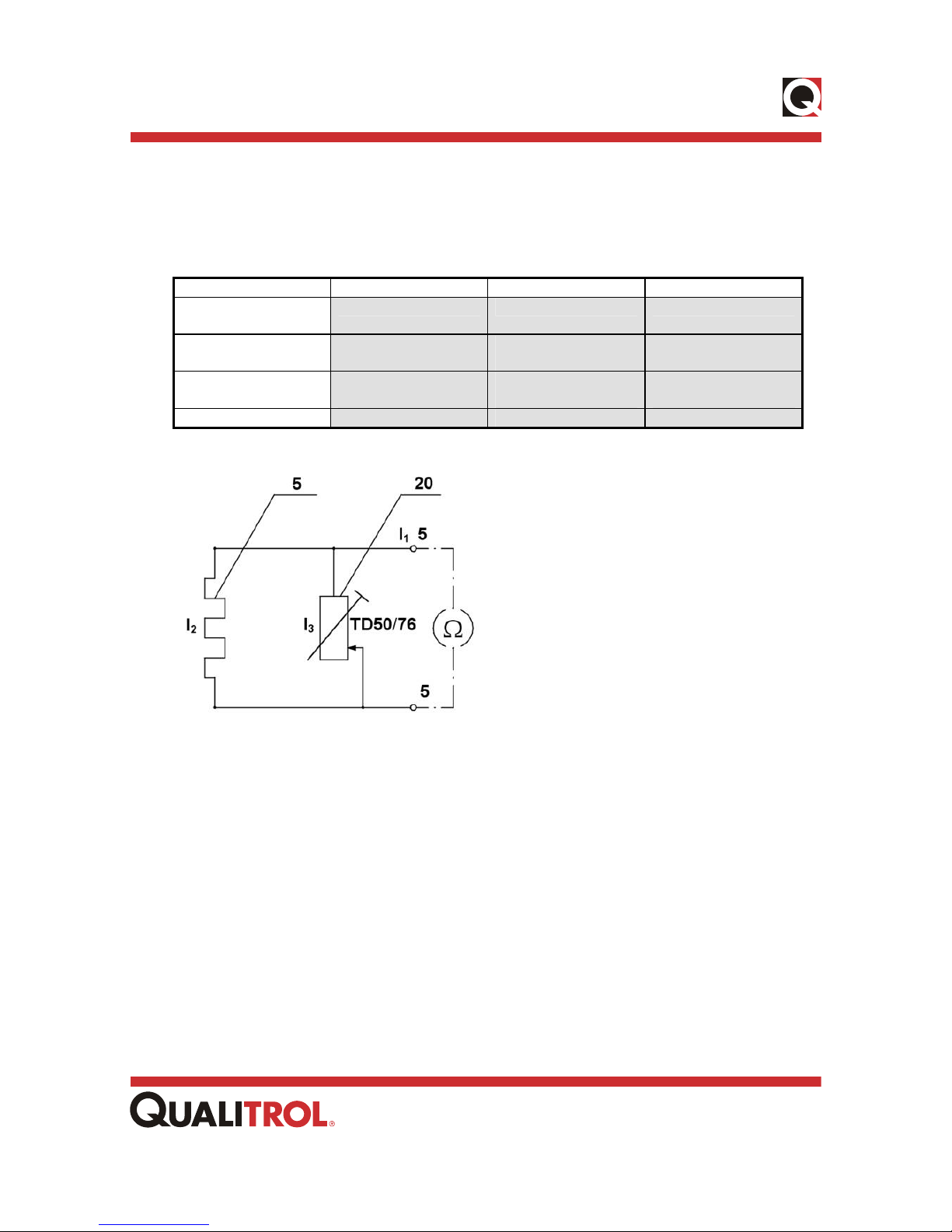

Figure 2 – TD Adjusting Schematic...................................................................................3

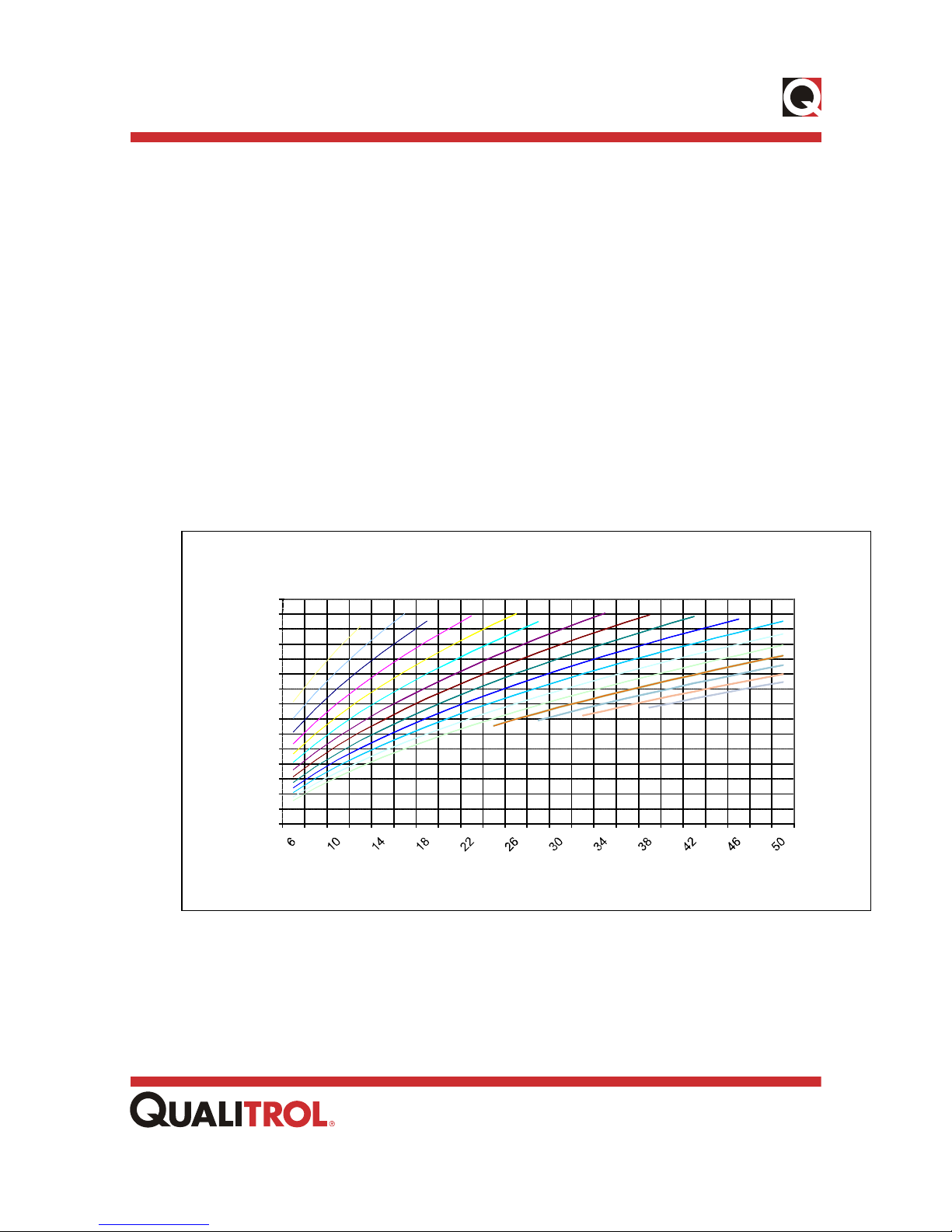

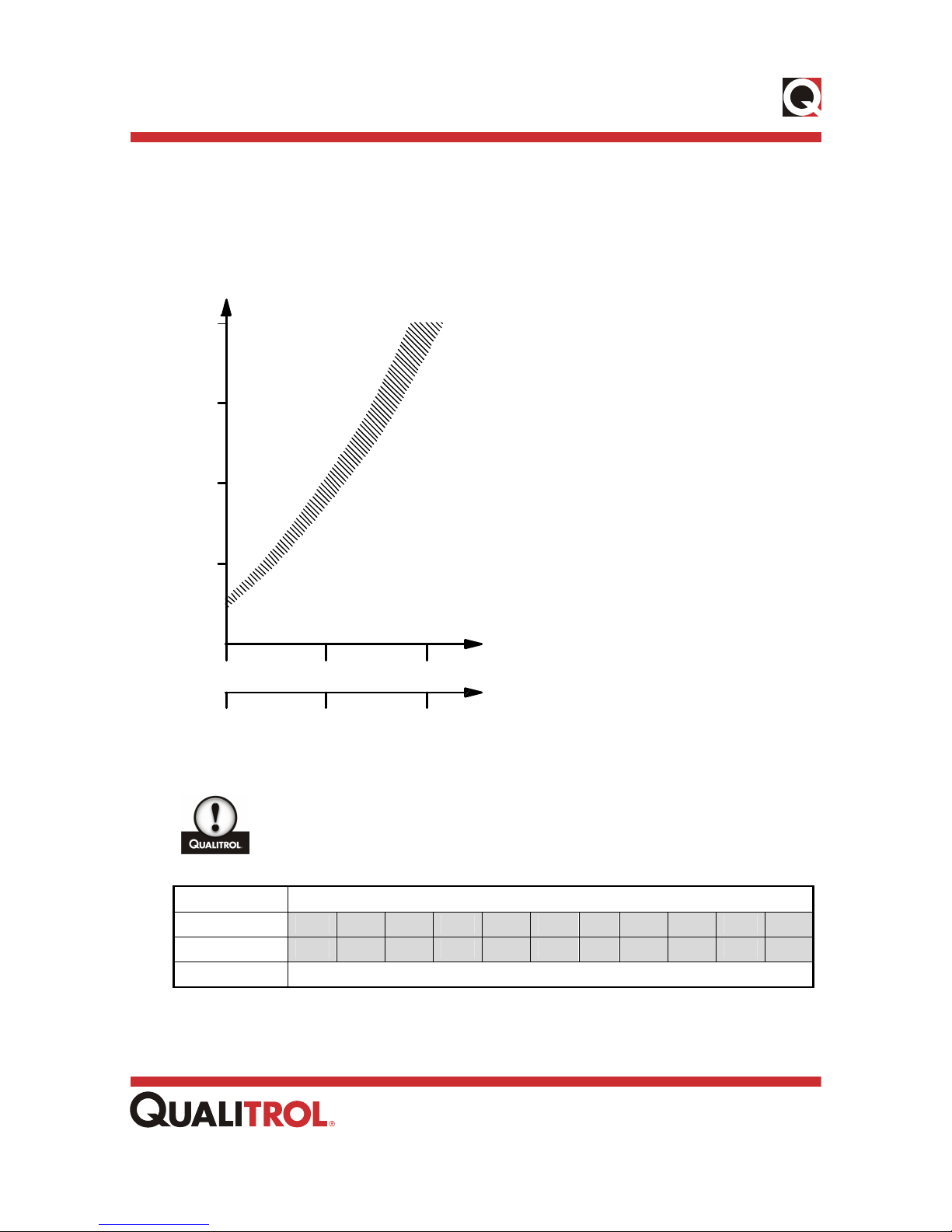

Figure 3 – Temperature Gradient Graph ...........................................................................4

Figure 4 – Guideline for Adjustment of Heating Current .................................................5

Figure 4.1 – Guideline for wiring Double Gradient Option ..............................................6

Figure 4.2 – TD50 / 5 Amp Wiring Example.......................................................................8

Figure 5 – Siesmic Mount...................................................................................................9

Figure 6 – Universal Mount ................................................................................................9

Figure 7 – Anti-Vibration (Standard) Mount....................................................................10

Figure 8 – Cover Hinge Side View ...................................................................................11

Figure 9 – Front Cover Removal......................................................................................11

Figure 10 – Switch Selection............................................................................................12

Figure 11 – 2 to 4 Switches w/Optional Heater and Remotes .......................................13

Figure 11.1 – 2 to 4 Switches w/Optional Heater and Remotes ....................................13

(TD50 5 Amp).....................................................................................................................13

Figure 11.2 – 2 to 4 Switches w/Optional Heater and Remotes ....................................13

(Double Gradient)..............................................................................................................13

Figure 12 – 5 to 6 Switches only......................................................................................14

Figure 13 – 5 to 6 Switches w/Optional heater and Remotes........................................14

Figure 14 – Pocket/Well Installation ................................................................................15

Figure 15 – 4-20mA Suggested Wiring TD111 ................................................................19

Figure 15.1 – 0-1mA Suggested Wiring TD119-1............................................................20

Figure 15.2 – 0-5mA Suggested Wiring TD119-2............................................................21

Figure 15.3 – 0-10mA Suggested Wiring TD119-3..........................................................22

Figure 15.4 – 0-20mA Suggested Wiring TD119-4..........................................................23