ECN-27433 August 25, 2009

i

Overview ______________________________________________________________1

QualiTROL Electronic Cooling Monitor..............................................................................1

QualiTROL..............................................................................................................................2

About This Manual .................................................................................................................2

Controls, Indicators, and Modules _________________________________________3

Front Panel...............................................................................................................................3

Modules ....................................................................................................................................4

509-RTD Input Module ......................................................................................................4

509-CT Input Module.........................................................................................................4

509-AC Voltage Input Module...........................................................................................4

509-Potentiometer Input Module........................................................................................4

509-DC Voltage Input Module...........................................................................................5

509-Current Input Module..................................................................................................5

509-Dry Contact Closure Module.......................................................................................5

509-Powered Contact Closure Module...............................................................................5

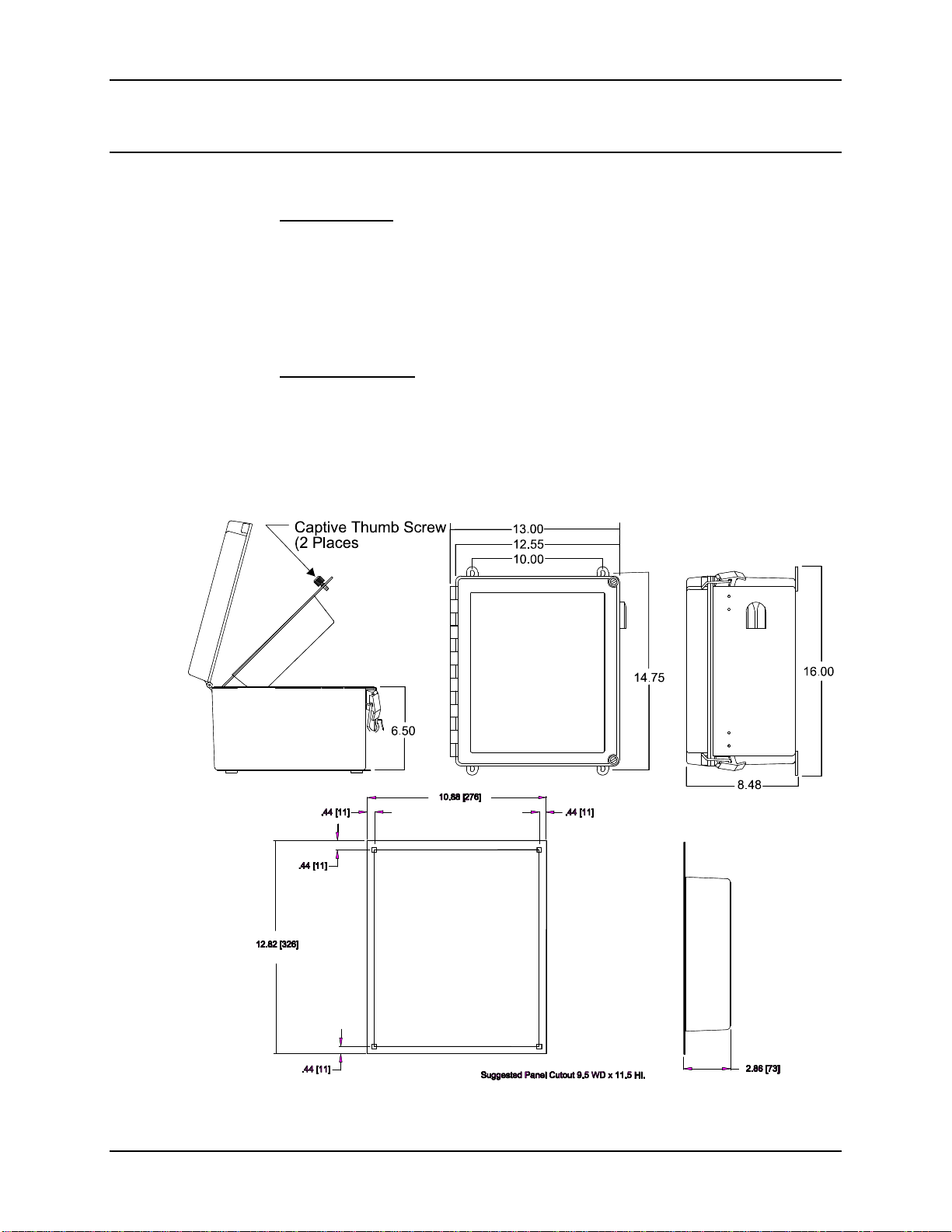

Installation_____________________________________________________________6

Location and Mounting...........................................................................................................6

Power Supply...........................................................................................................................7

Heater Option..........................................................................................................................9

RTD Input Module................................................................................................................10

CT input Module...................................................................................................................11

AC Voltage Input Module.....................................................................................................11

Potentiometer Input Module................................................................................................11

DC Voltage Input Module.....................................................................................................12

Current Input Module ..........................................................................................................13

Dry Contact Closure Input Module.....................................................................................14

Powered Contact Closure Input Module.............................................................................14

Output Contacts ....................................................................................................................14

Remote Output Signals.........................................................................................................15

Communications....................................................................................................................16

Operation_____________________________________________________________18

Automatic Operation ............................................................................................................18