QUALITROL AKM345 GEN3 OTIWTITM Instruction Manual

40-08847-00-Rev001

www.qualitrolcorp.com Page 4 of 34

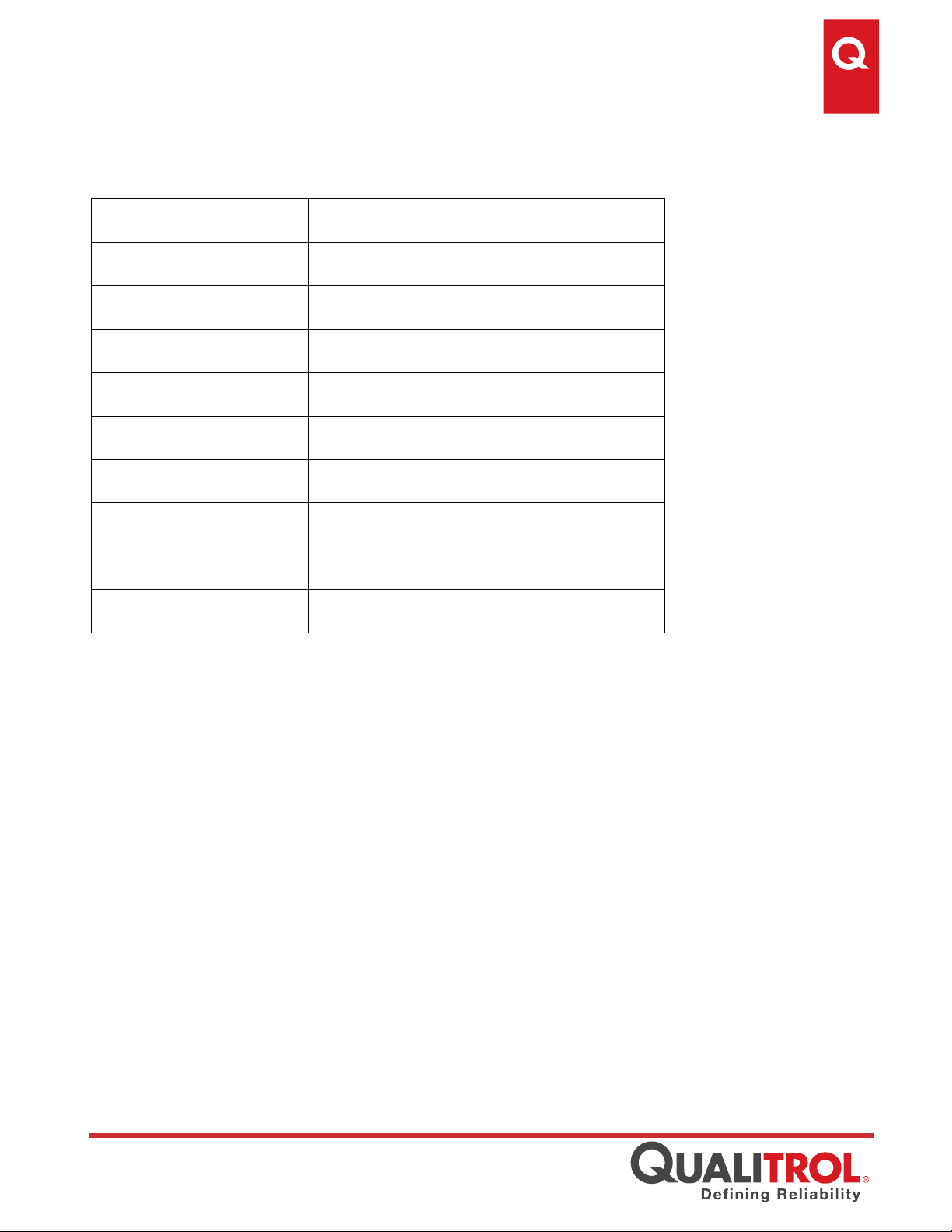

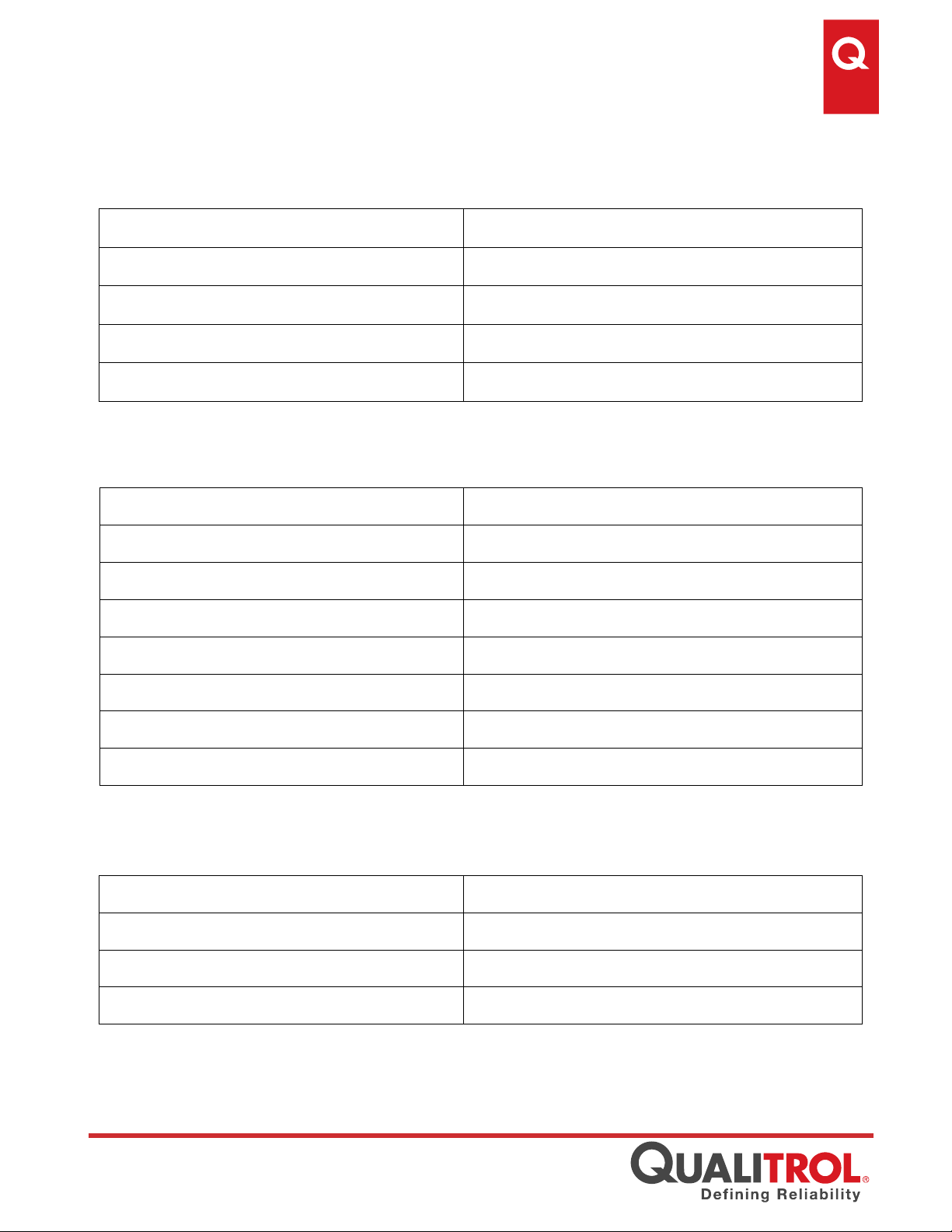

Table of Contents

1. List of Abbreviations/Acronyms......................................................................................................................... 6

2. Introduction....................................................................................................................................................... 7

2.1 QUALITROL AKM345 GEN3 OTIWTITM........................................................................................................ 7

2.2 Operation................................................................................................................................................... 8

2.3 Calibration Check....................................................................................................................................... 8

2.4 Winding Simulation.................................................................................................................................... 8

2.5 Switches..................................................................................................................................................... 8

2.6 Remote Output.......................................................................................................................................... 9

2.7 MODBUS .................................................................................................................................................... 9

3. Specifications..................................................................................................................................................... 9

3.1 Environmental.......................................................................................................................................... 10

3.2 Electrical................................................................................................................................................... 10

3.3 Mechanical............................................................................................................................................... 10

3.4 SCADA ...................................................................................................................................................... 11

4. Safety ............................................................................................................................................................... 11

4.1 General Warnings .................................................................................................................................... 11

4.2 Capillary Routing...................................................................................................................................... 12

4.3 Switch Wiring........................................................................................................................................... 12

4.4 Electrical Connection ............................................................................................................................... 12

4.5 Power Connection.................................................................................................................................... 13

4.6 4-20 mA Current Loop ............................................................................................................................. 13

4.7 0-5 Volt Signal.......................................................................................................................................... 13

5. Installation ....................................................................................................................................................... 13

5.1 Mounting the AKM345 ............................................................................................................................ 13

5.1.1 Mounting the Enclosure .................................................................................................................. 13

5.1.2 Installing the Probe.......................................................................................................................... 15

5.2 Front Cover .............................................................................................................................................. 17

5.2.1 Opening and propping ..................................................................................................................... 17

5.2.2 Cover Removal................................................................................................................................. 18

5.3 Electrical Connection ............................................................................................................................... 19

5.3.1 Cable Glands .................................................................................................................................... 19

5.3.2 Switches........................................................................................................................................... 19

5.3.3 Matching Resistance........................................................................................................................ 20