Page 1 of 14

Copyright © 2009 Quality Water Treatment, All right reserved. rev. 10.29.09 www.qualitywatertreatment.com

INSTALLATION & START-UP INSTRUCTIONS

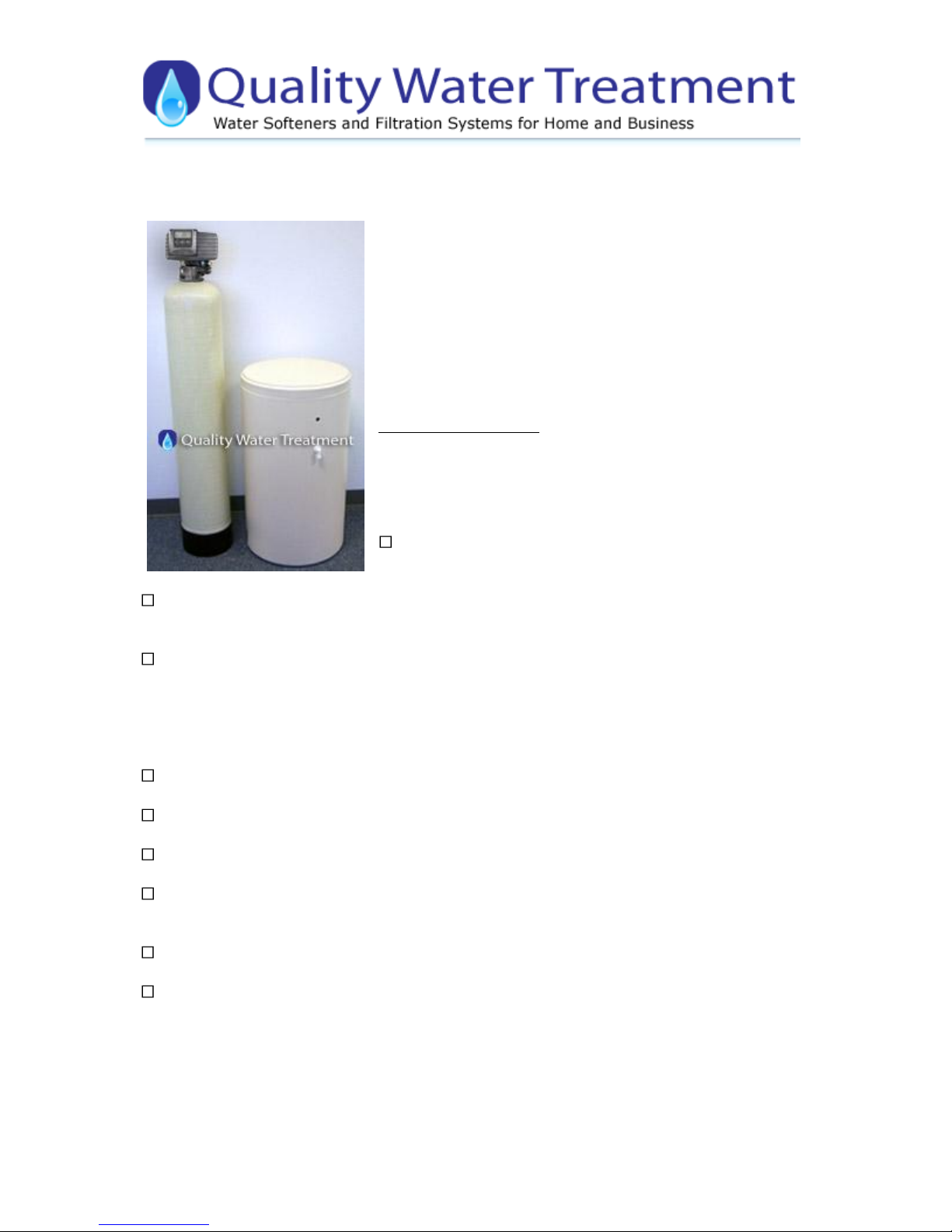

FLECK 5600 SXT Metered WATER SOFTENER

Thank you for your purchase of a new Water Softener

with Fleck 5600SXT Meter water softener from Quality

Water Treatment! We have put together these

instructions as a reference, and they are to be used as a

general installation guideline.

Pre-Installation Guide

Before you assembly your new system, be sure that the

following conditions have been met for placement of your

system:

Level, firm surface, such as concrete, on which to place the

softener tank and salt tank AKA Brine Tank

Nearby floor drain or standpipe to connect to the softener for use during each

regeneration

Standard US plug, 120v 60hz (the softener system includes a 5ft. power cord and plug. Be

sure the plug is not connected to a light switch

Make a list of all the plumbing fittings to completely install the unit

Typical is:

Two - 3/4" or 1” male adaptors

Eight - 90°elbows

Amount of pipe you need

1/2" drain line and 90°elbows

Adding the Resin to the Water Softener Tank

1. Position your new softener unit where you want it placed for use.

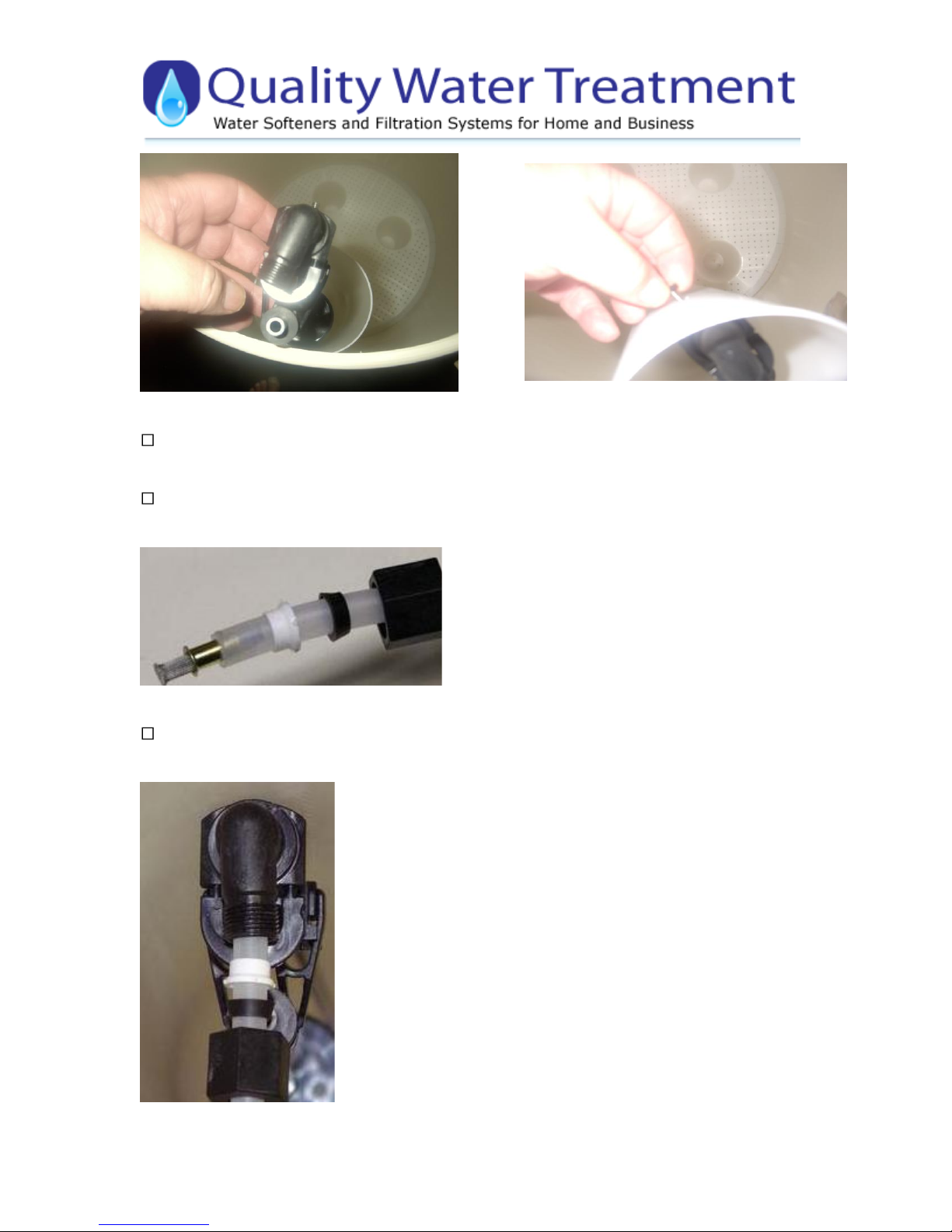

2. Inside the Softener tank you’ll find a 3/4" or 1" gray or white Pvc tube (called a

distributor tube.) If the tube does not already have a cap on the top use a pvc slip cap or

some duct tape to temporarily plug this tube (this is to keep the resin from going down the

tube.) If your system came with gravel, add the gravel first, then the resin. Use the included

special funnel when adding the resin. This will take about 10 minutes.