Inhalt

1 Technical data FD 10 ....................................................................................................................... 3

2 Drawings.......................................................................................................................................... 4

2.1 Normal rods RS pushing function / lintel mounting................................................................ 4

2.2 Sliding rods RG pulling function / lintel mounting .................................................................. 5

2.3 Sliding rods RG pushing function / lintel mounting ................................................................ 6

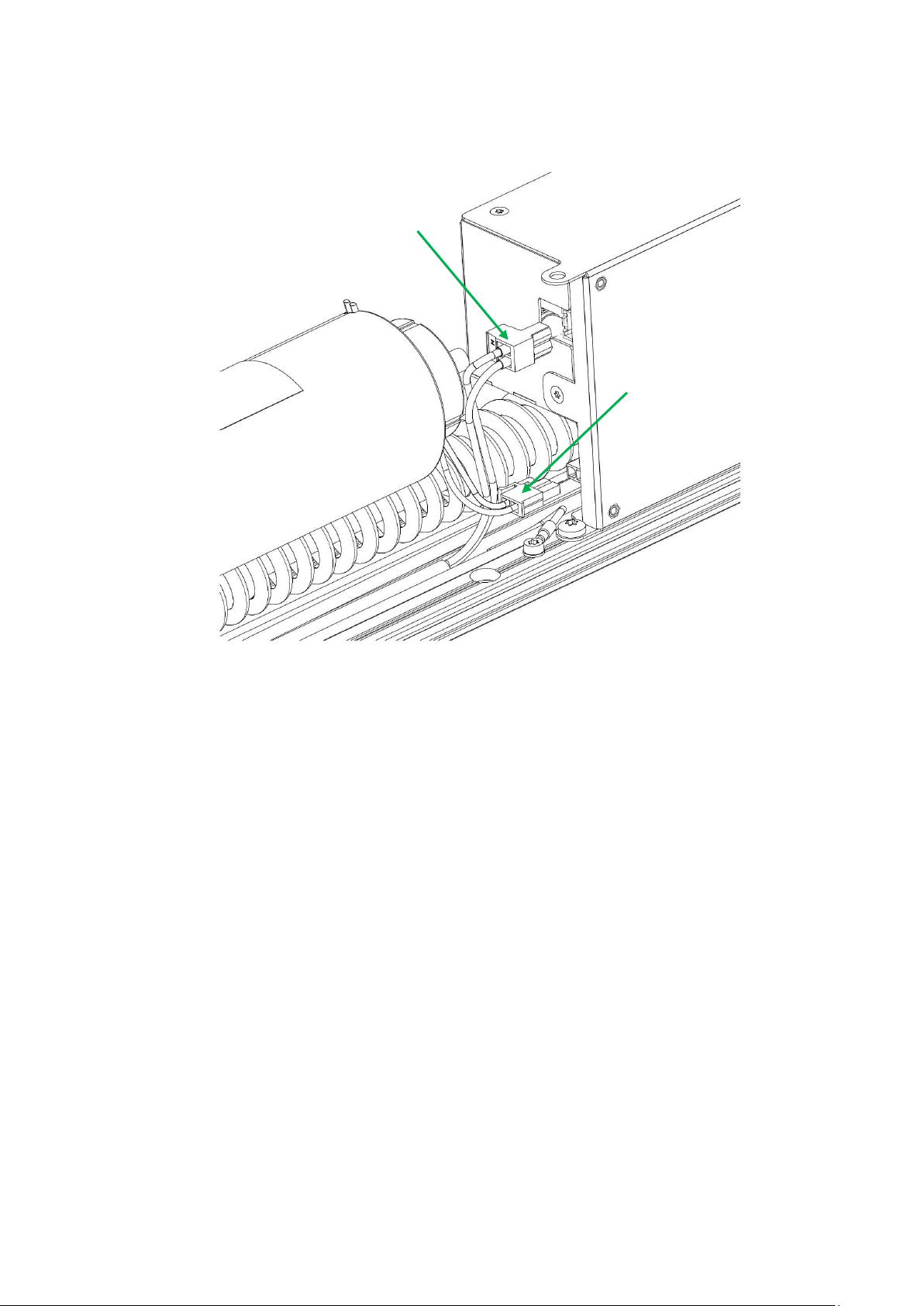

3 Mounting......................................................................................................................................... 7

4 Automatic closing sequence control ............................................................................................. 14

5 Control........................................................................................................................................... 16

6 Commissioning .............................................................................................................................. 17

7 Adjustments .................................................................................................................................. 19

7.1 Motion parameters (PARAMETER)........................................................................................ 19

7.2 Configuration (CONFIG)......................................................................................................... 20

7.3 Installation with multiple door leaves (Double Door)........................................................... 21

8 Menu navigation ........................................................................................................................... 22

8.1 PARAMETER........................................................................................................................... 22

8.2 CONFIG .................................................................................................................................. 22

8.3 DOUBLE DOOR....................................................................................................................... 23

8.4 DIAGNOSTICS......................................................................................................................... 23

8.5 ERROR ACTIVE ....................................................................................................................... 23

8.6 HISTOR ERROR....................................................................................................................... 23

8.7 REINIT .................................................................................................................................... 23

8.8 BLOCK/UNBLOC..................................................................................................................... 24

8.9 TEACH .................................................................................................................................... 24

9 Troubleshooting ............................................................................................................................ 25

9.1 Drive mechanism................................................................................................................... 25

9.2 Operating............................................................................................................................... 25

9.3 Safety elements..................................................................................................................... 26

9.4 Feeding .................................................................................................................................. 26

9.5 System ................................................................................................................................... 26

9.6 Options .................................................................................................................................. 26

9.7 Closing sequence................................................................................................................... 26

10 Malfunction without error-no....................................................................................................... 27