Subject to change without notice!

EN

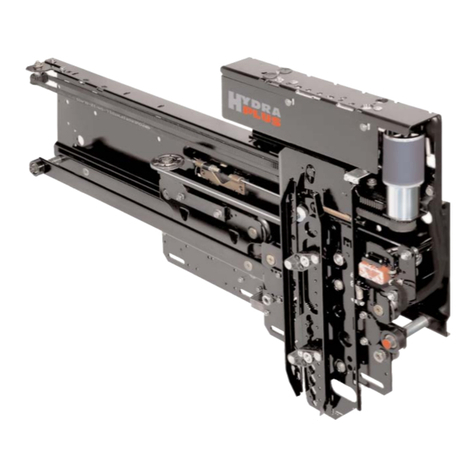

HYDRA PLUS UD300 CAR DOOR Code

Version

Code

Version

Date

Page

GM.2.002668.EN

B

3201.32.0397

B

04.02.2013

1.37

INDEX

11..GGeenneerraallddeessccrriippttiioonn.............................................................................

...............................................................................................................33

1.1 Operator fixing on car roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

22..FFiittttiinnggaannddaaddjjuussttiinnggbbrraacckkeettss....................................................

....................................................................................................................88

33..LLaannddiinnggddoooorraalliiggnnmmeennttwwiitthhccaarrddoooorr...........................................

.............................................................................................................88

44..AAsssseemmbbllyyooffppaanneellffiixxiinnggbboollttss........................................................

................................................................................................................99

55..CClleeaarraanncceerreeccoovveerriinnggoofftthheeppaanneellaasssseemmbblliinnggbboollttss.................................

...............................................................................................1111

66.

.BBoottttoommsslliiddiinnggsshhooeessaasssseemmbbllyy,,mmaaiinntteennaanncceeaannddrreeppllaacceemmeenntt.........................................

...................................................................1122

77..FFiittttiinnggccaarrssiillllbbrraacckkeettss..

.....................................................................................................................................................................