Ref: EM4446/EGO400-UM-Rev.B. UK 2

Thank you for choosing this caravan mover. This product has been produced according to very high standards and has undergone

careful quality control procedures. Simply by using the remote control you can move your caravan eortlessly into any position

required within operating guidelines.

Before proceeding with installation and starting to use the mover, please read this manual very carefully and be aware of

all the safety instructions! The owner of the caravan will always be responsible for correct use. Keep this manual inside

your caravan for future reference.

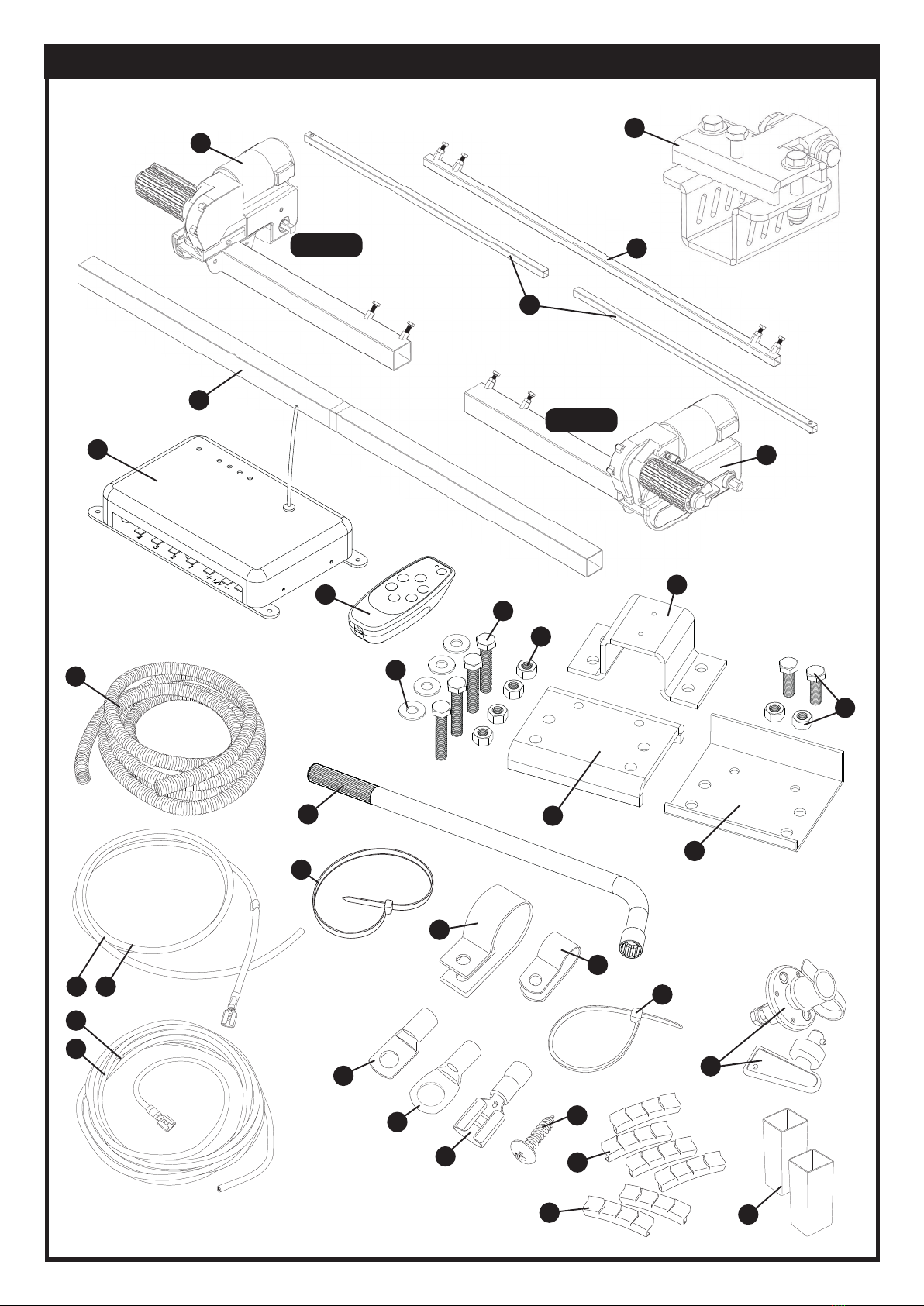

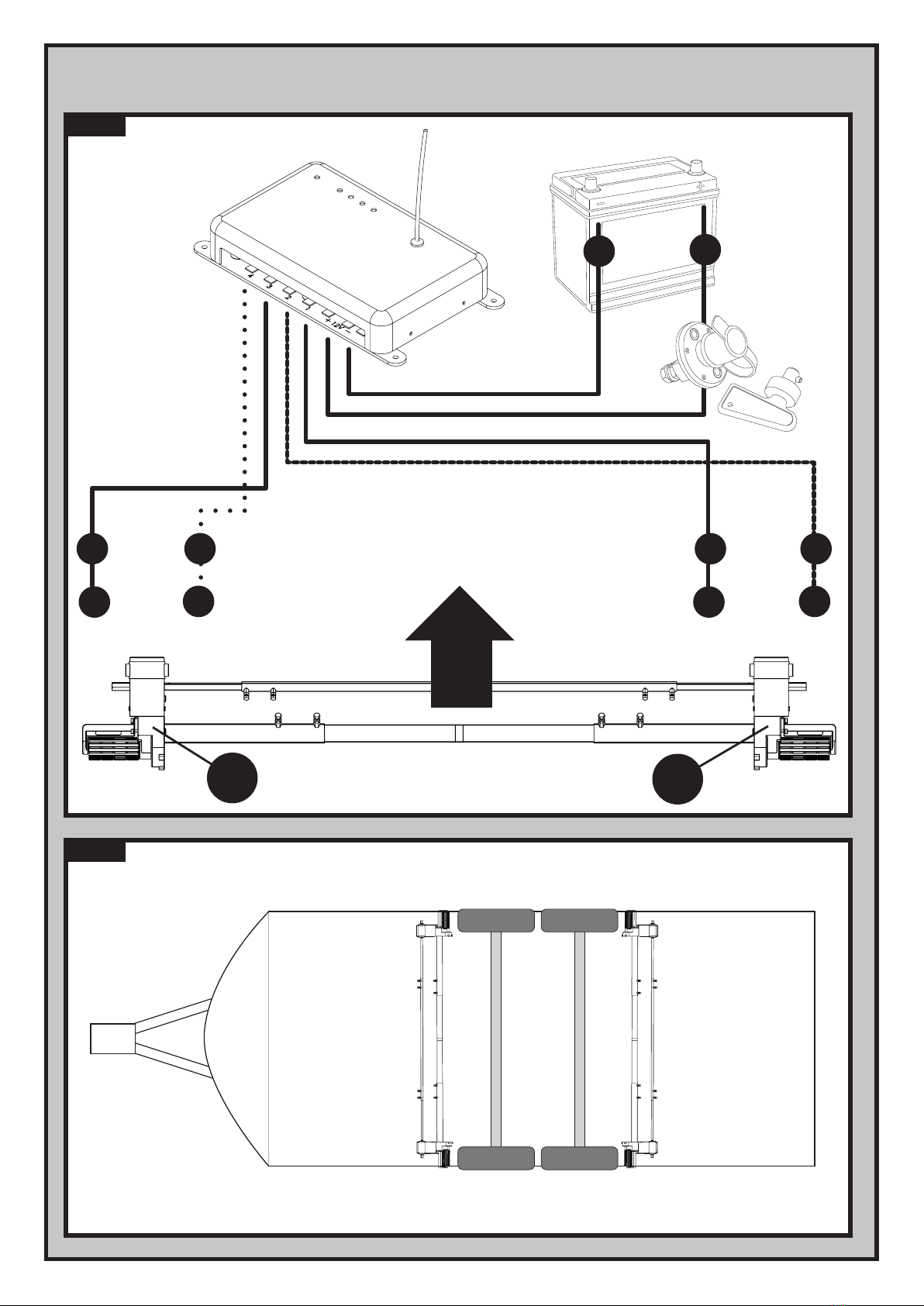

This User Manual covers two models of Caravan Mover: Model No. EGO400 and Model No. EM4446; any installation or operational

dierences between the two models are detailed where appropriate. The caravan mover consists of two 12V motor-powered

rollers, a 12V electronic control box and a remote control. To function, the motor-powered rollers must be engaged against the

tyres of your caravan. The supplied cross actuation device enables you to engage both rollers at the same time from one side of

your caravan. Once this is done the mover is ready for operation. The remote control will allow you to move your caravan in any

direction.

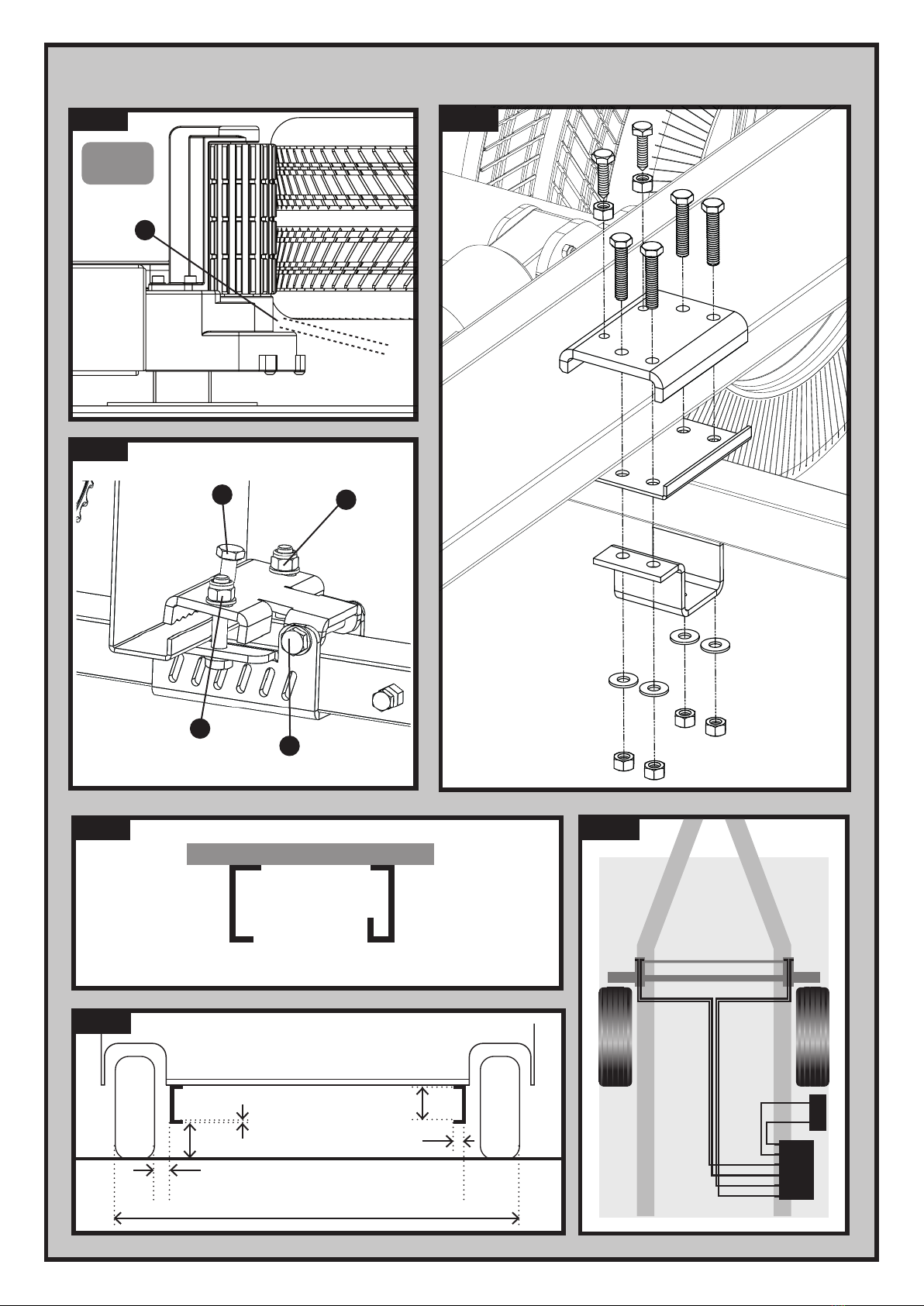

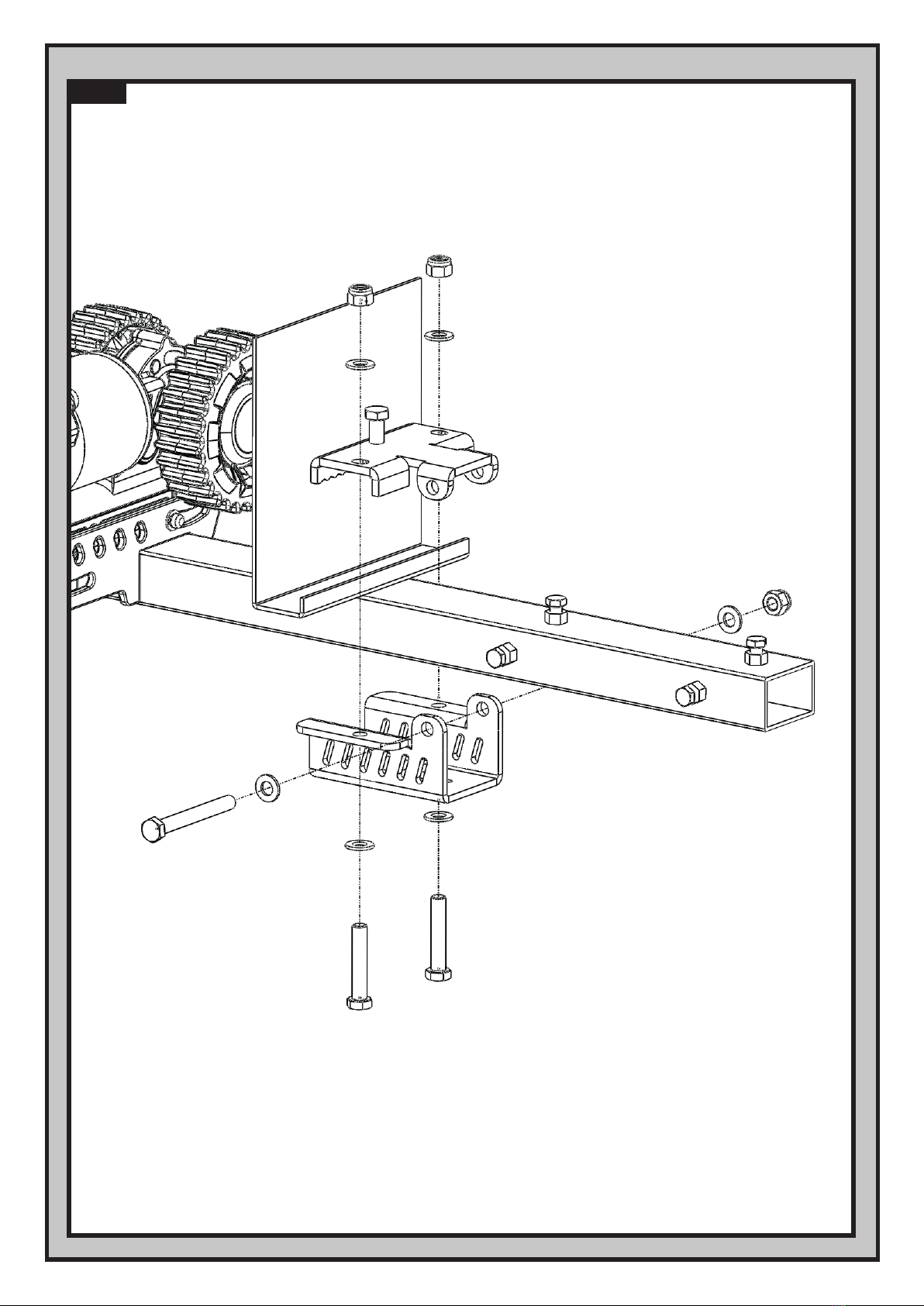

The chassis clamps provided are suitable for tment onto most standard caravan chassis that have an L-shape or U-shape prole.

Please refer to Fig.17 & Fig.18 for reference on dimensions and clearances BEFORE you proceed any further with installation.

If your chassis has dierent dimensions to those shown in Fig.18 then various chassis clamp adapters are available to suit the

majority of UK and Continental caravans; please refer to the section entitled ‘Optional Fitting Adapters’.

Note: Adjustment of this manner is only available with the Classic Clamp option.

* Average Current Consumption readings when using an approx. 1100Kg single axle caravan on a hard, level surface.

** Maximum Current Consumption readings when using an approx. 1100Kg single axle caravan ascending a 1:4 (25%) gradient.

These symbols identify important safety precautions.

They mean CAUTION! WARNING! SAFETY FIRST! IMPORTANT INFORMATION!

Specications

Installation Safety Guidelines

Important Safety Instructions

Read this User Manual carefully before installation and use. Failure to comply with

these rules could result in serious injury or damage to property.

Introduction

Fitting Guidelines

Model Number EGO400 EM4446

Operational Voltage 12 Volt DC 12 Volt DC

Average Current Consumption* 25 Ampere (approx) 25 Ampere (approx)

Maximum Current Consumption** 76 Ampere (approx) 76 Ampere (approx)

Speed 12cm per sec. (approx) 9cm per sec. (approx)

Approx. Net Weight (inc. all xings & accessories) 35 Kg 40 Kg

Safe Working Load (SWL) Twin Motor/Quad Motor 2250Kg/3500Kg 2250Kg/3500Kg

Minimum Width (caravan/trailer) 1800mm 1800mm

Maximum Width (caravan/trailer) 2500mm 2500mm

Power Source (caravan leisure battery) 12V 12V