Table of Contents

016-0171-655 Rev. E i

Chapter 1 Important Information.......................................................................................... 1

Safety ...............................................................................................................................................................................1

Displays and Control Consoles .........................................................................................................................................1

Agricultural Chemical Safety ..............................................................................................................................................2

Electrical Safety .......................................................................................................................................................................2

Touch Screen ............................................................................................................................................................................2

Recommendations and Best Practices ................................................................................................................3

Harness Routing ......................................................................................................................................................................3

Chapter 2 Introduction............................................................................................................. 5

Make and Model Information ................................................................................................................................5

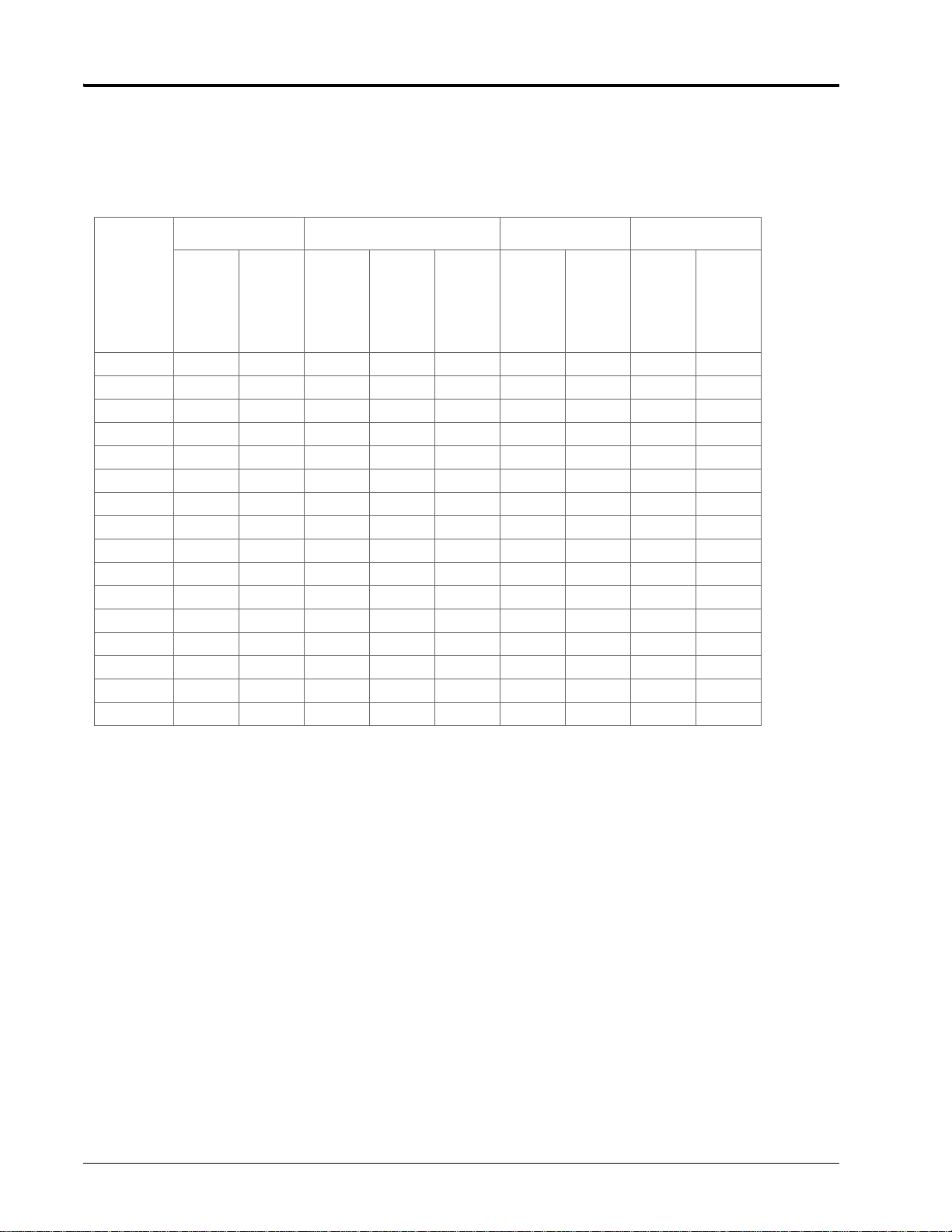

Boom Spacing ..........................................................................................................................................................................6

Software Requirements ........................................................................................................................................................6

Machine Configuration Notes ...........................................................................................................................................6

Overview of the Installation Process ....................................................................................................................7

Required Components .........................................................................................................................................................7

Tools and Materials Needed ..............................................................................................................................................7

Point of Reference ..................................................................................................................................................................7

Kit Contents ...................................................................................................................................................................8

Updates ........................................................................................................................................................................15

Chapter 3 Installation Preparation ...................................................................................... 17

Chapter 4 Nozzle Control Valve Installation..................................................................... 19

Hawkeye Nozzle Control Valve Installation ....................................................................................................19

Best Practices and Recommendations .........................................................................................................................19

ProStop-E with Wilger Nozzle Body Assembly .........................................................................................................20

Boom Cable Routing and Connection ..............................................................................................................25

Best Practices and Recommendations .........................................................................................................................25

Secondary Boom Cable Routing and Connections .................................................................................................25

Primary Boom Cable Routing and Connections .......................................................................................................27

Chapter 5 ISOBUS ECU Mounting and Connection......................................................... 29

Product Controller II ECU Installation ...............................................................................................................29

Best Practices and Recommendations .........................................................................................................................29

Electrical Box Preparation .................................................................................................................................................29

Mounting Plate Preparation and ECU Installation ...................................................................................................32

In Cab Connections .............................................................................................................................................................32

ECU Electrical Connections ...............................................................................................................................................33

Chapter 6 Chassis Cable Installation................................................................................... 35

Chassis Cable Routing and Connection ...........................................................................................................35

Best Practices and Recommendations .........................................................................................................................35

Electrical Box Connections ................................................................................................................................................35

Center Rack Routing and Boom Cable Connections ..............................................................................................36

Hawkeye Power Connections (No Injection) .................................................................................................37

Battery Compartment and Connections ......................................................................................................................38