FENIX G Operating manual

- page 6 -

CONTENTS

I. PREFACE ................................................................................................................................................... 8

II. GENERAL................................................................................................................................................... 8

III. WARNING SIGNS .................................................................................................................................... 8

IV. GENERAL GUIDELINES ON SAFETY AND ACCIDENTS PREVENTION........................................................... 9

V. NOISE AND VIBRATIONS.......................................................................................................................... 10

VI. HYDRAULICS......................................................................................................................................... 10

VII. MAINTENANCE..................................................................................................................................... 10

VIII. RESTRICTIONS ON TRAVELING ON PUBLIC ROADS ................................................................................ 11

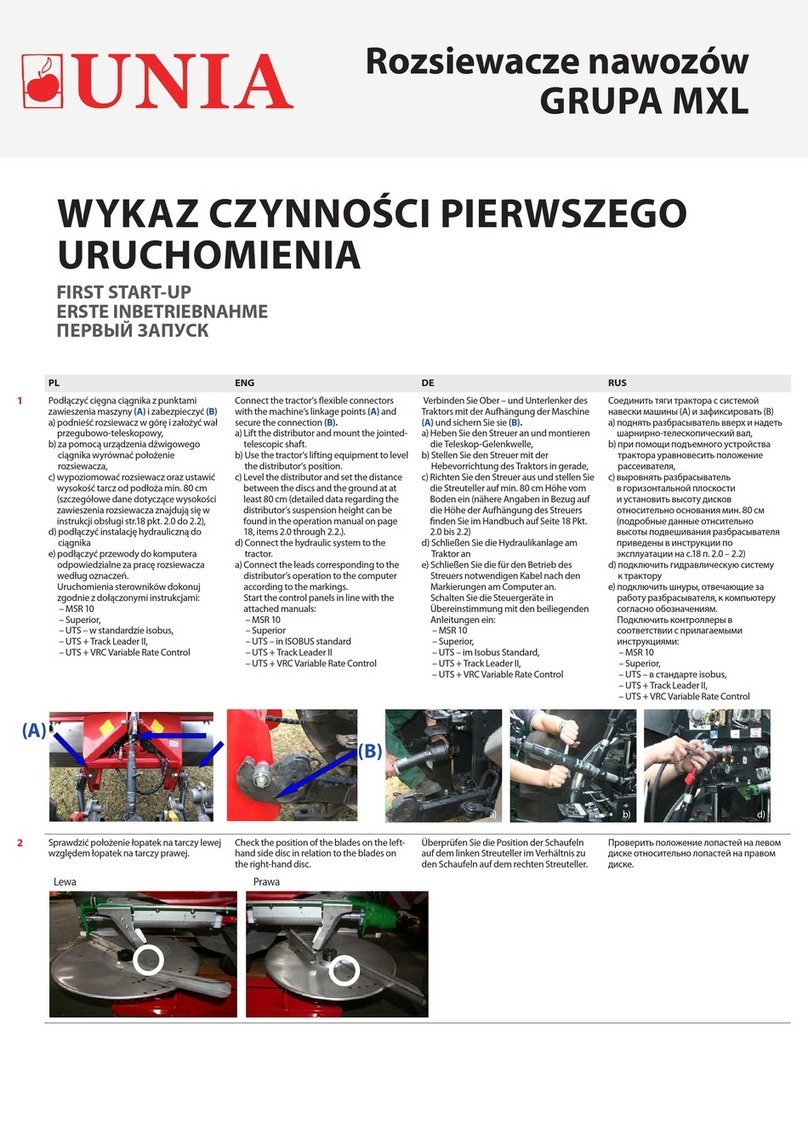

IX. PREPARATION FOR THE FIRST START-UP............................................................................................... 12

X. GENERAL AND COMMERCIAL INFORMATION. REPAIR DURING THE WARRANTY PERIOD. ........................ 13

XI. USER MANUAL ..................................................................................................................................... 14

1. INTENDED USE.................................................................................................................................. 14

1.1. Technical data ............................................................................................................................... 15

2. CONSTRUCTION AND OPERATION..................................................................................................... 15

2.1. Main Assemblies of the seed drill. ................................................................................................. 15

3. USING THE MACHINE........................................................................................................................ 17

3.1. Loading and Unloading.................................................................................................................. 17

3.2. Connecting and Setting the Blower................................................................................................ 17

3.3. Operation and Setting of Metering Unit......................................................................................... 19

3.3.1. Calibration test on the FENIX G seed drill. .................................................................................. 19

3.3.2. Checks during sowing................................................................................................................. 21

3.3.3. Adjustment of seed Amount ...................................................................................................... 22

3.3.4. Operation of the Seed Dispenser................................................................................................ 23

3.4. Filling and Emptying the Seed Hopper and Dispenser. ................................................................... 25

3.5. Track markers................................................................................................................................... 26

3.6. The depth of the cultivation. ......................................................................................................... 27

3.7. Work with the unit and operating conditions................................................................................. 27

4. Daily Maintenance............................................................................................................................ 28

4.1. Maintenance Intervals................................................................................................................... 28

4.2. Storage.......................................................................................................................................... 29

4.3. Lubrication .................................................................................................................................... 29

4.4. Hydraulic System Maintenance and Use ........................................................................................ 30

4.5. Lighting Installation. ......................................................................................................................... 32

5. Disassembly and decommissioning. .................................................................................................. 32