(Pt)

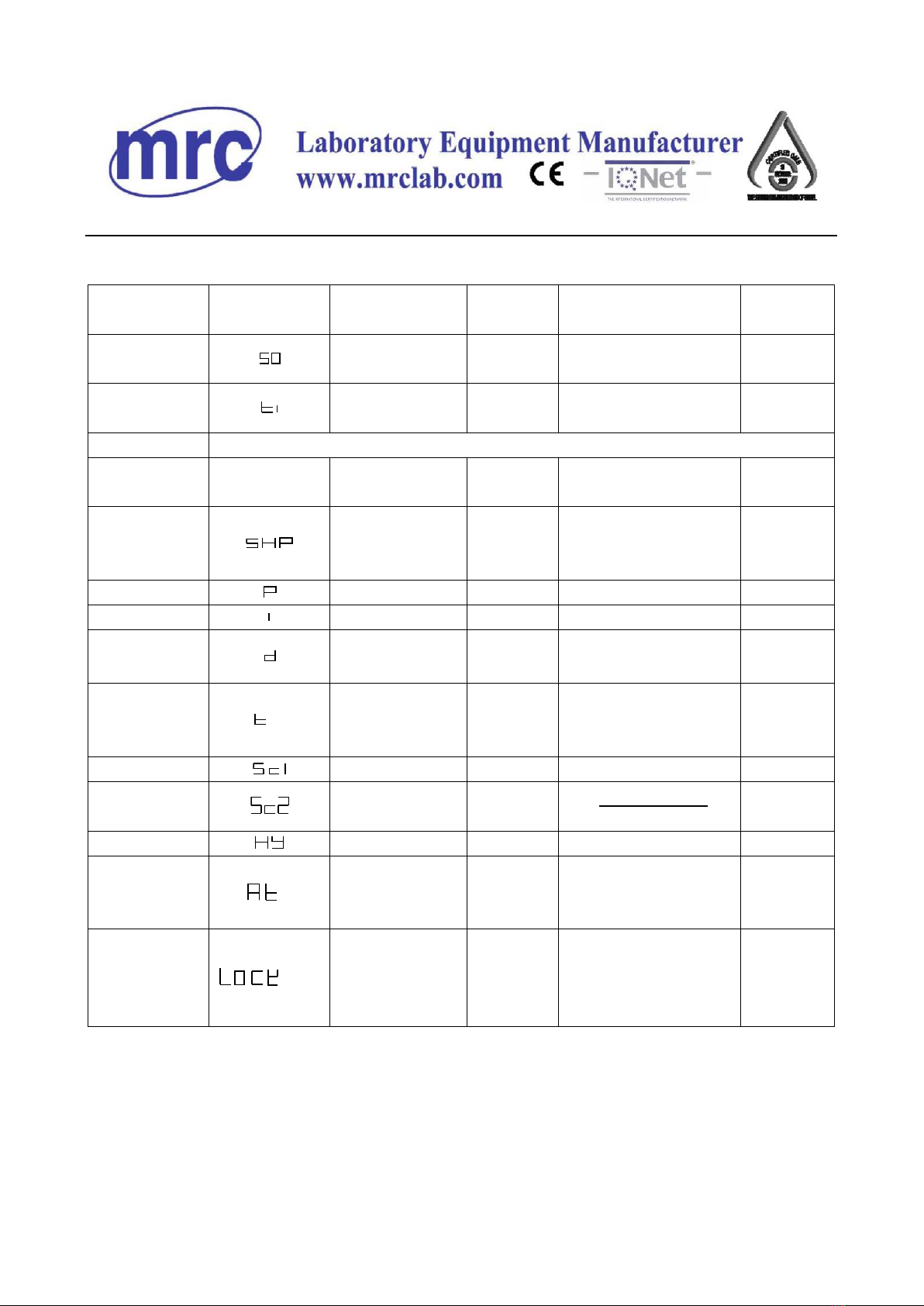

(2) Press the SET function key for 1 second to enter the first menu, the upper row displays ,

which is the required set temperature, and then press the SET function key, the upper row displays

,which is the required time setting, and then press the SET function key to save.

(3) Press the SET function key for 5 seconds to enter the setting parameters required by the second

menu (according to Table 1), and then press the SET function key for 5 seconds to save the setting

value.

4.1 Self-tuning function of the meter

Press for 5 seconds, appear set symbol ,and self-adjusting begins; when self-

adjusting ends, off, then get a group of PID parameters overcoming excessive temperature.

During self-adjusting, press for 5 seconds and off, then self-adjusting ends. The meter

will be controlled following the original PID parameters.

If the temperature rise is slow, use a parameter that is several tens of degrees higher than the

self-tuning parameter to control the required time speed.

4.2 Time function:

Press key and then the total power up time shows in minutes. In case of power failure, the

previous timer is invalid. When the caller calls, start the timer from zero again.

4.3.Time setting up function:

According to the first menu in Table 1, the upper row of the meter displays , and the lower row

sets the time.

When the time needed by the meter is up, lower row shows off and output function ends. If you

want to resume control time setting up, you should select power off first, then restart. Long-term

heat preservation is required, and the time is set to "0"

4.4 If it displays LLL, it means that the sensor is short-circuited or the temperature is less than -20℃;

if it displays HHH, it means that the sensor is open or the temperature is greater than the

measurement range.

Note: When using the vacuum oven, if the sensor is placed inside the oven, and it is self- adjustment

at 140℃. The reference number is for example: I=392+200=592.P=848.D=637. The period is set

to 40 seconds..

If the sensor is placed outside the box, it will be self-tuning at 160°C. The reference number is for

example: I=350+300=650.P=1060.D=1007. The period is set to 60 seconds.

When using the vacuum oven, after self- adjustment, the PID parameters remain unchanged, and

the period is set to 5-10 seconds.