Operation Procedures:

• Unlock all locking mechanisms and ensure

that the doors are free of obstructions.

• Turn the Power Switch to the “on” position,

located on the upper left hand corner.

• Proper operation of the “Up-Eye” unit requires

the attendant to be directly in front of and

over all 3 photoelectric sensors while serv-

ing. Proper operation of the “Thru-Beam” unit

requires the attendant to stand between the

Emitter and Receiver eyes.

• <Note> The outside edge of the photo-bar

should be lined up with the outside edge of

the locking jamb.

General Cleaning Guidelines:

• All weather-stripping should be checked and

cleaned weekly.

• All glass, aluminum framing, stainless steel,

and plastic eye covers & lens should be kept

clean at all times. All cleaning uids and ap-

plicators should be non-abrasive.

General Maintenance:

• Slide rail system should be kept clean and re-

oiled with lightweight oil every six (6) months.

• The hook lock and thumb turn should be

cleaned of any grease or grime build up every

six (6) months.

• The eye covers, whether “Up-Eye” or “Thru-

Beam, should be cleaned of any dirt or debris

daily with a non-abrasive cleaner.

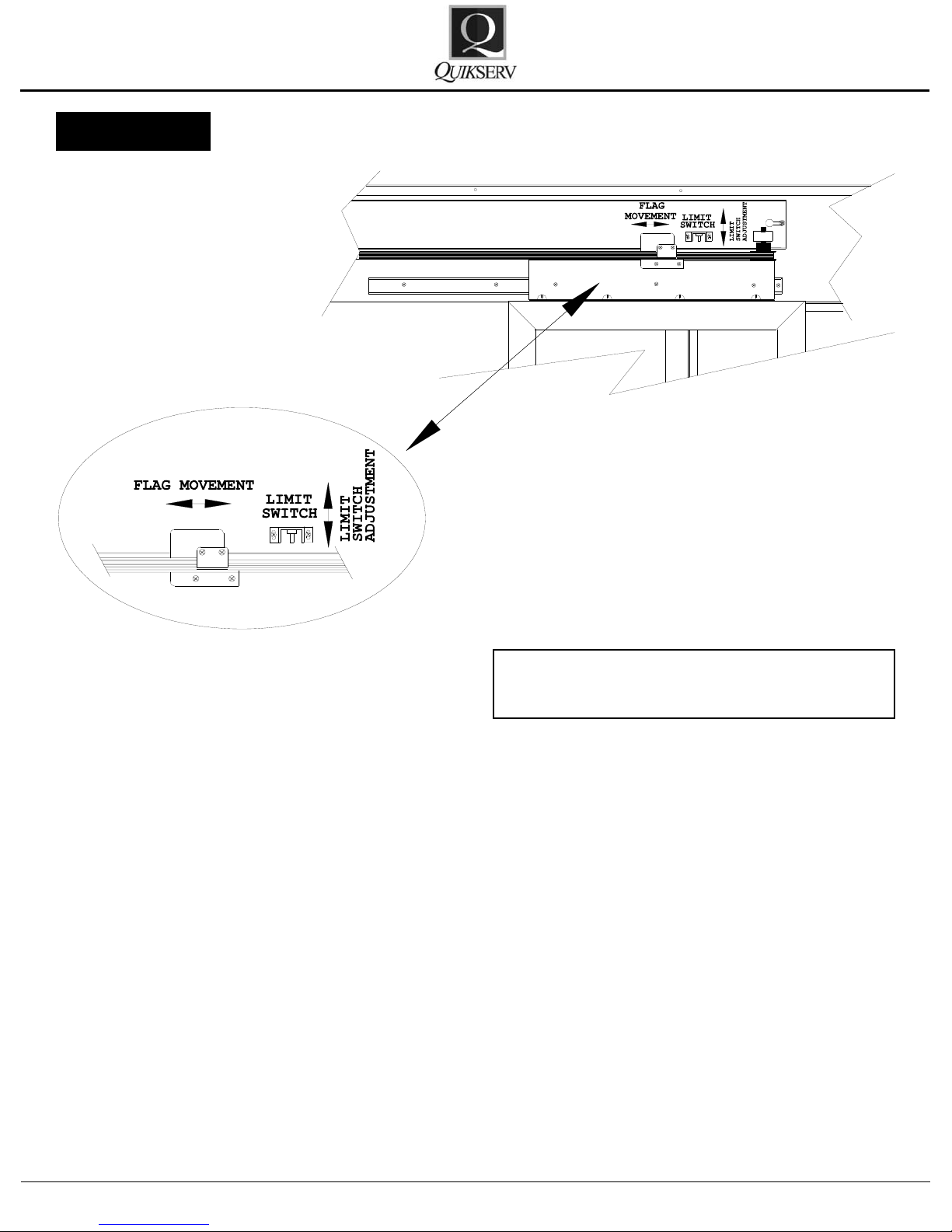

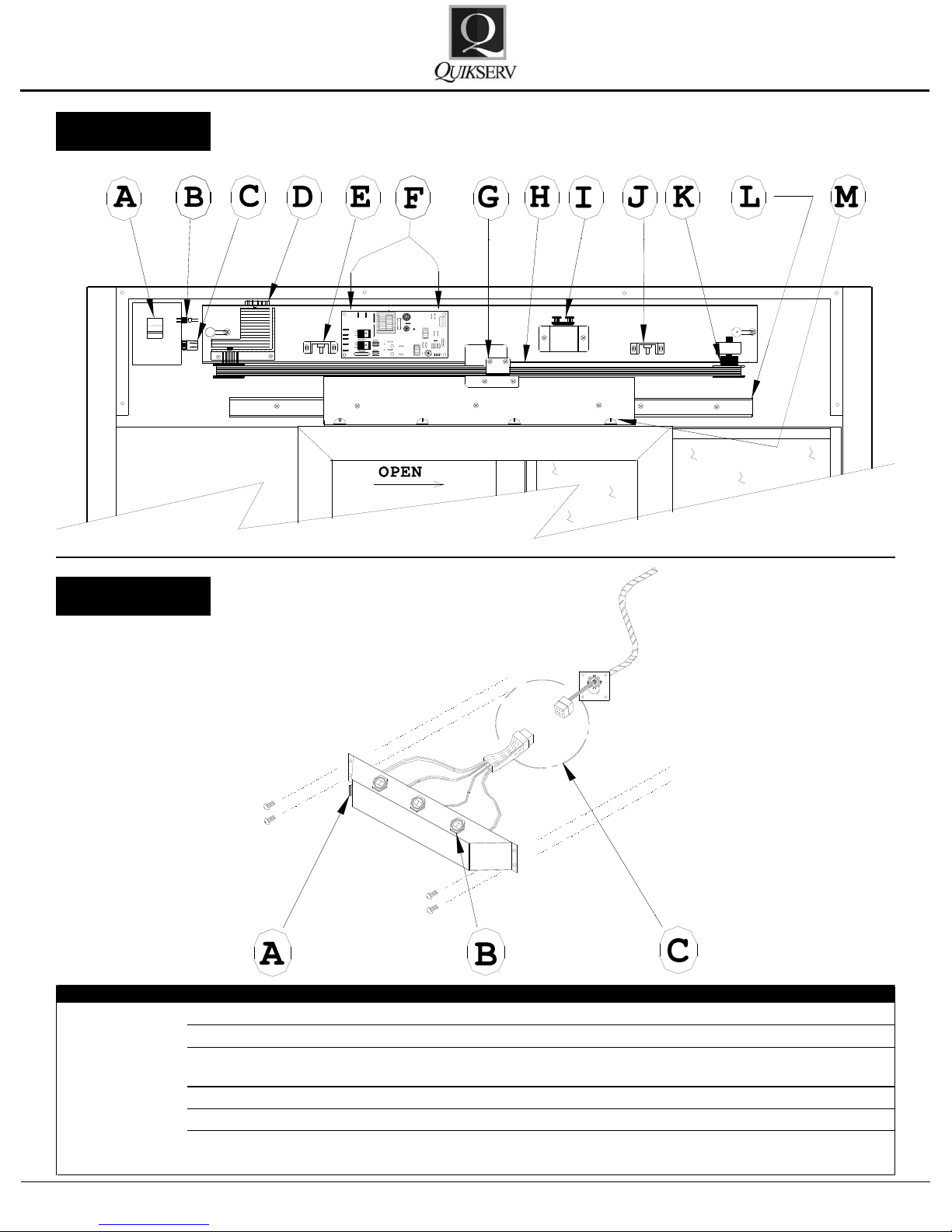

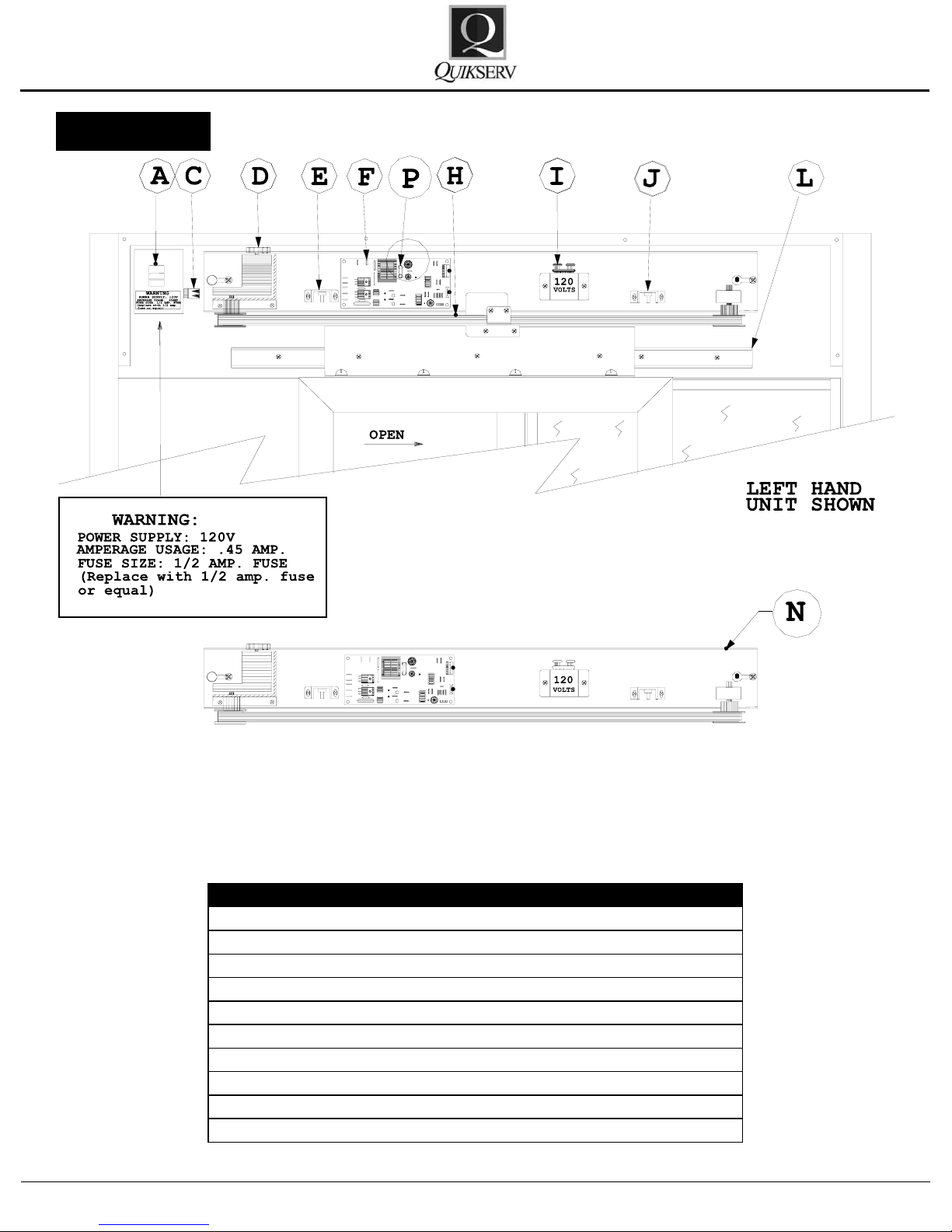

To gain access to the internal compo-

nents for each window, the access panel

must be removed.

Service Manual SST-4035E

2

Quikserv Corp.©quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

Automatic Slider

Operation and Maintenance Procedures

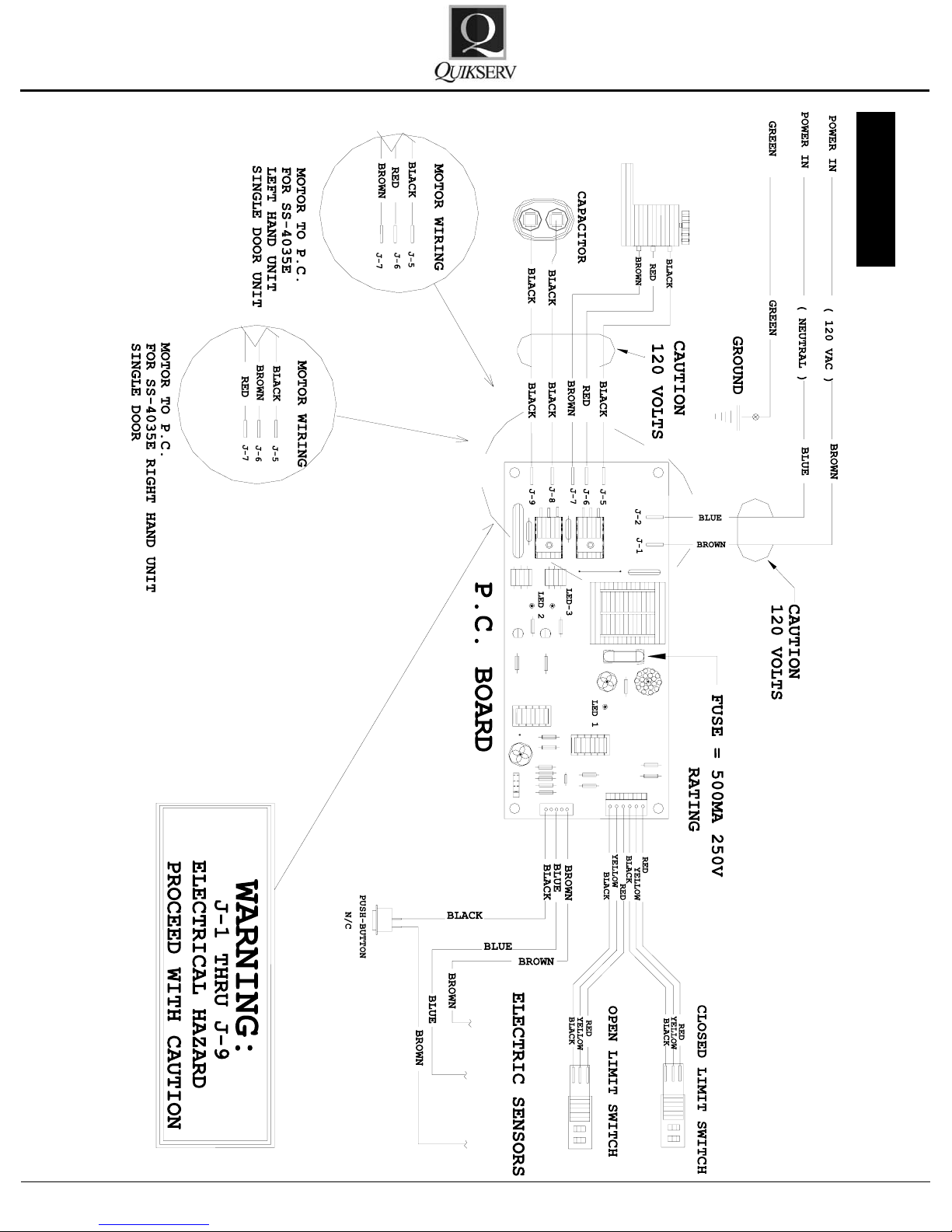

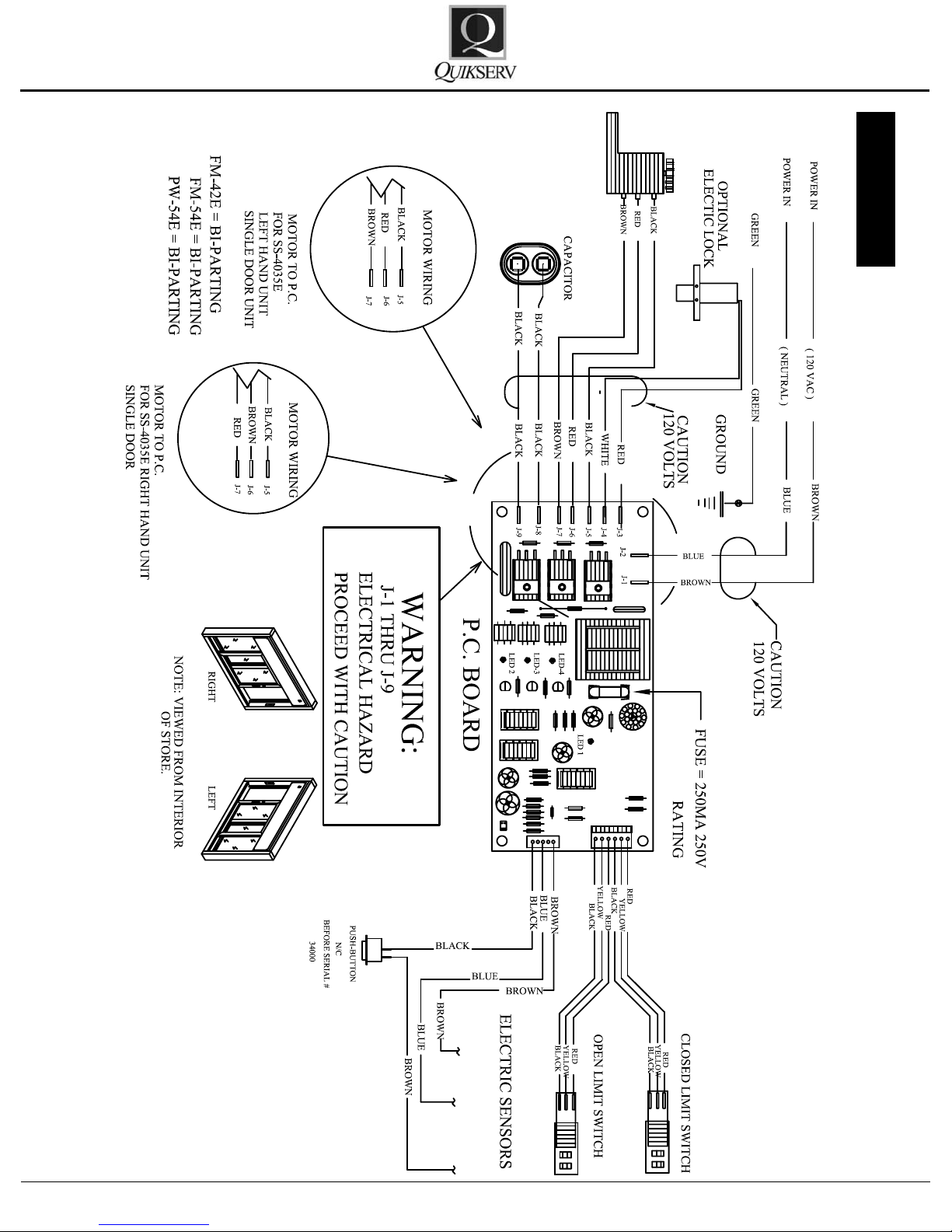

Warning

For your own safety, turn

power switch OFF before

removing the access

panel.