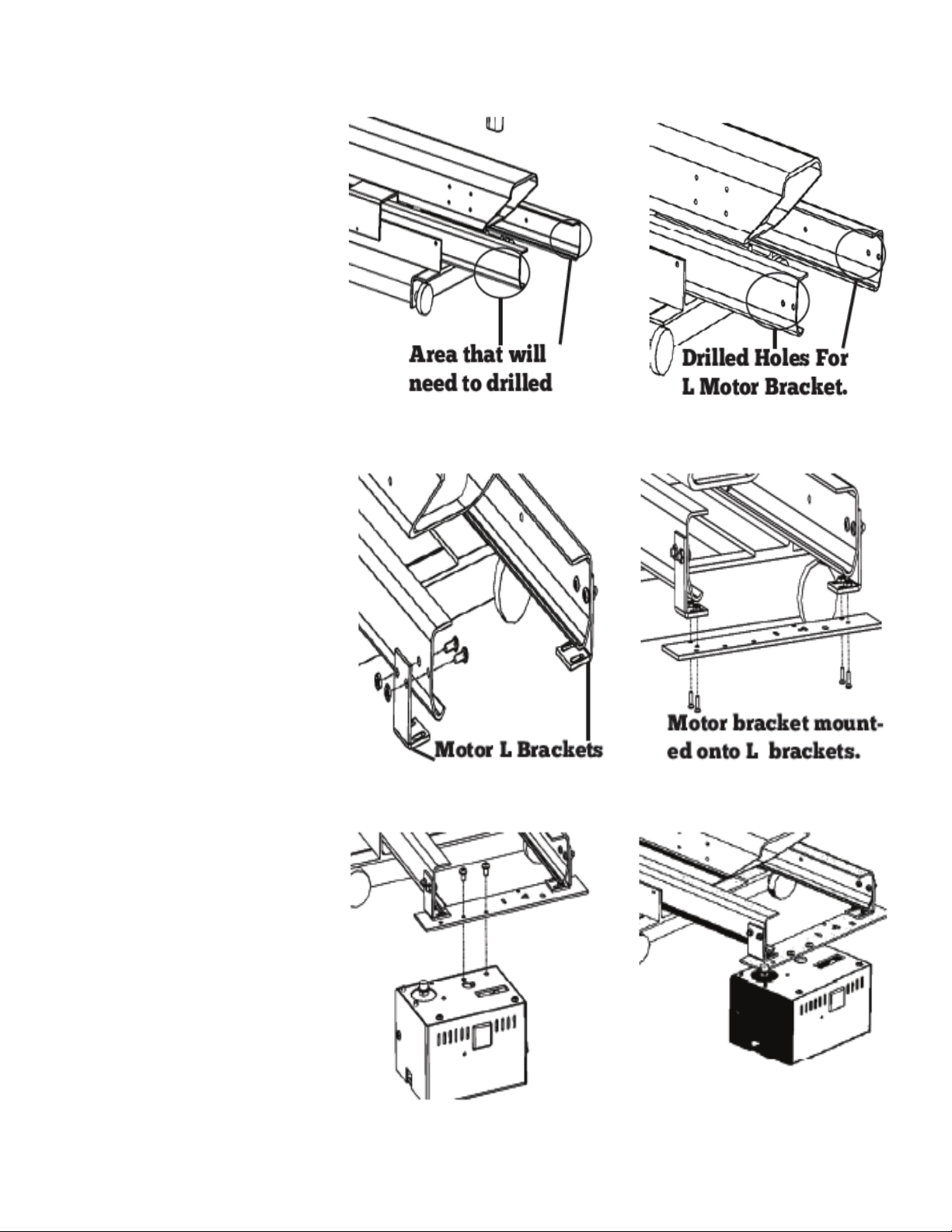

Page 8

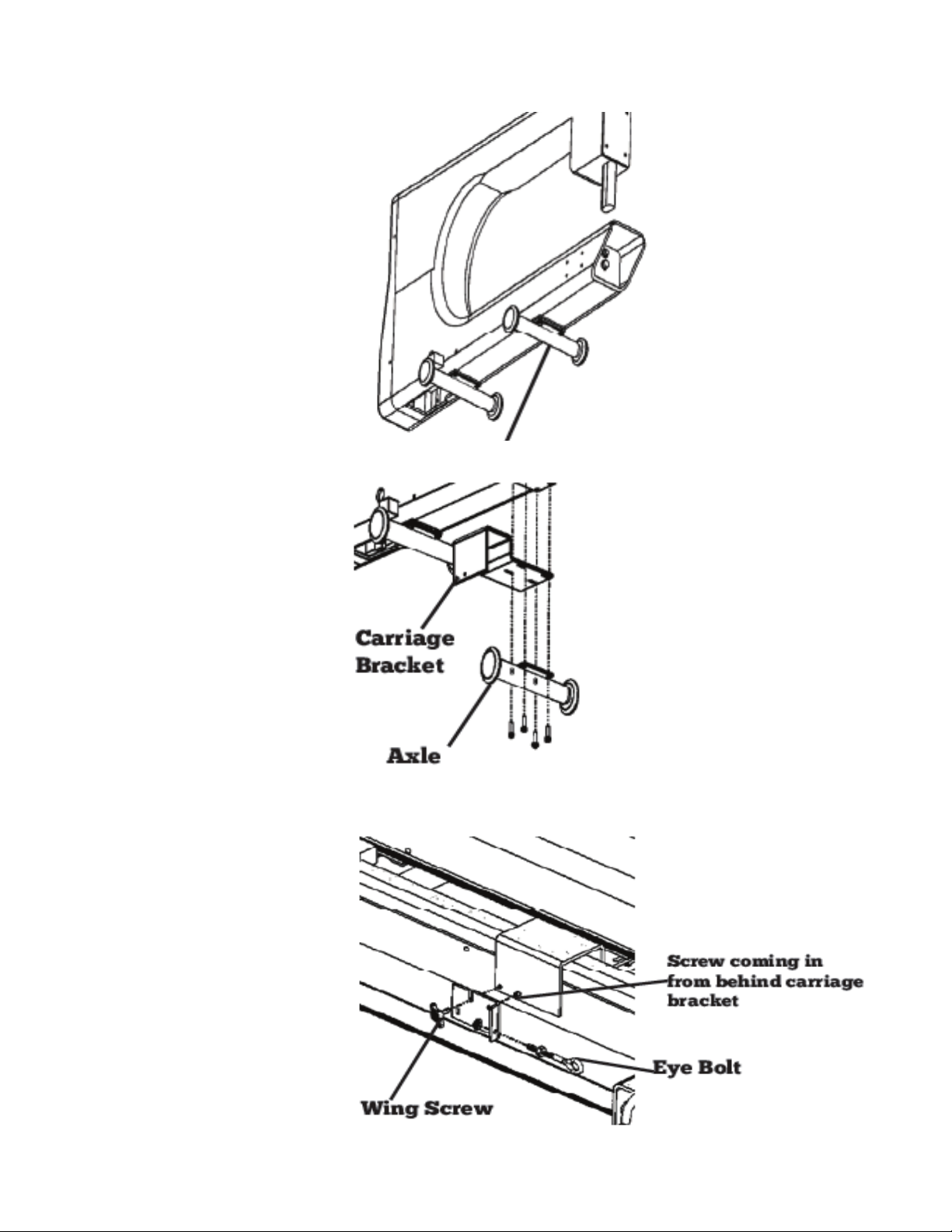

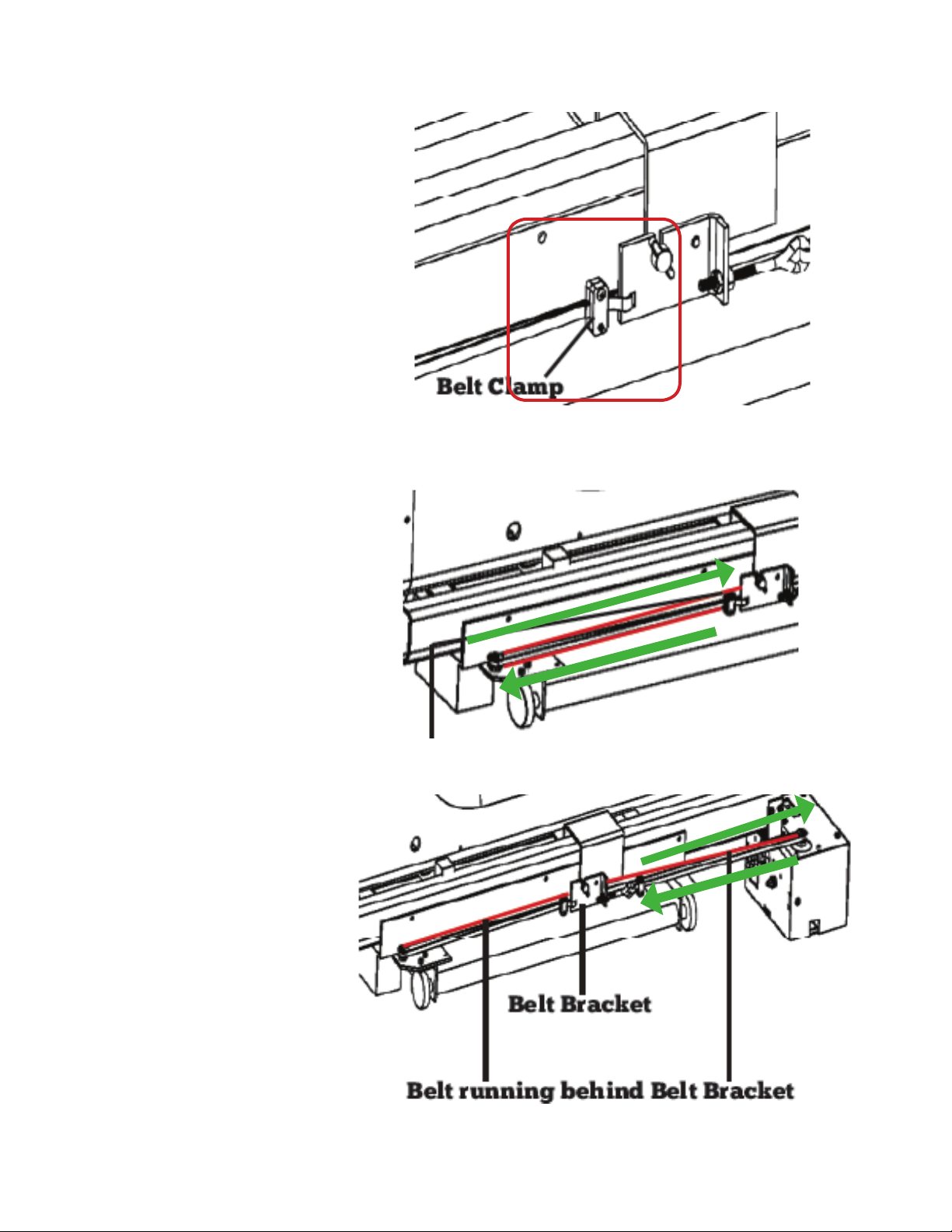

4Attach the remaining end

of the belt to the to the

eye bolt with a belt clamp.

Tighten the eye bolt as

needed to tighten the

belt. It should have some

play, but not a lot.

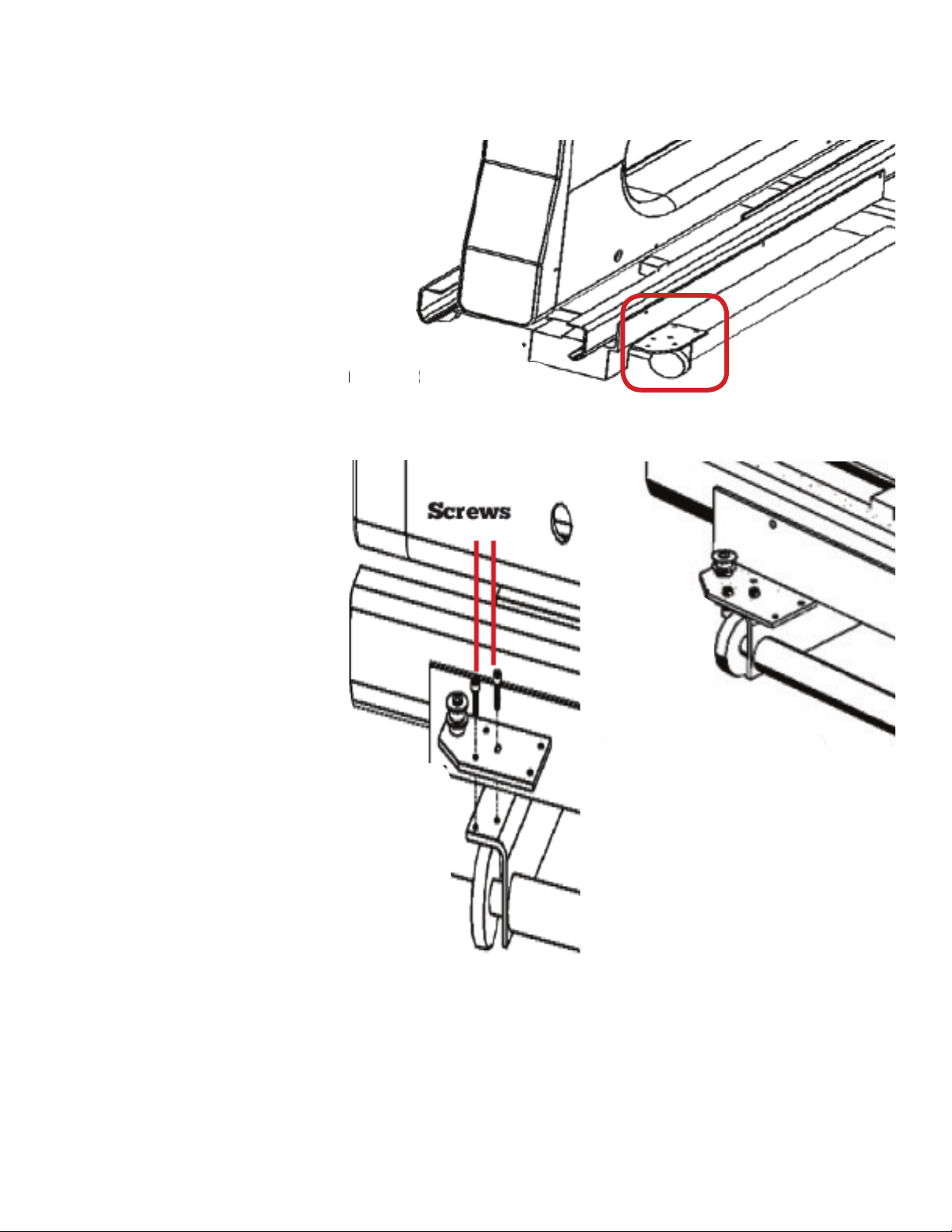

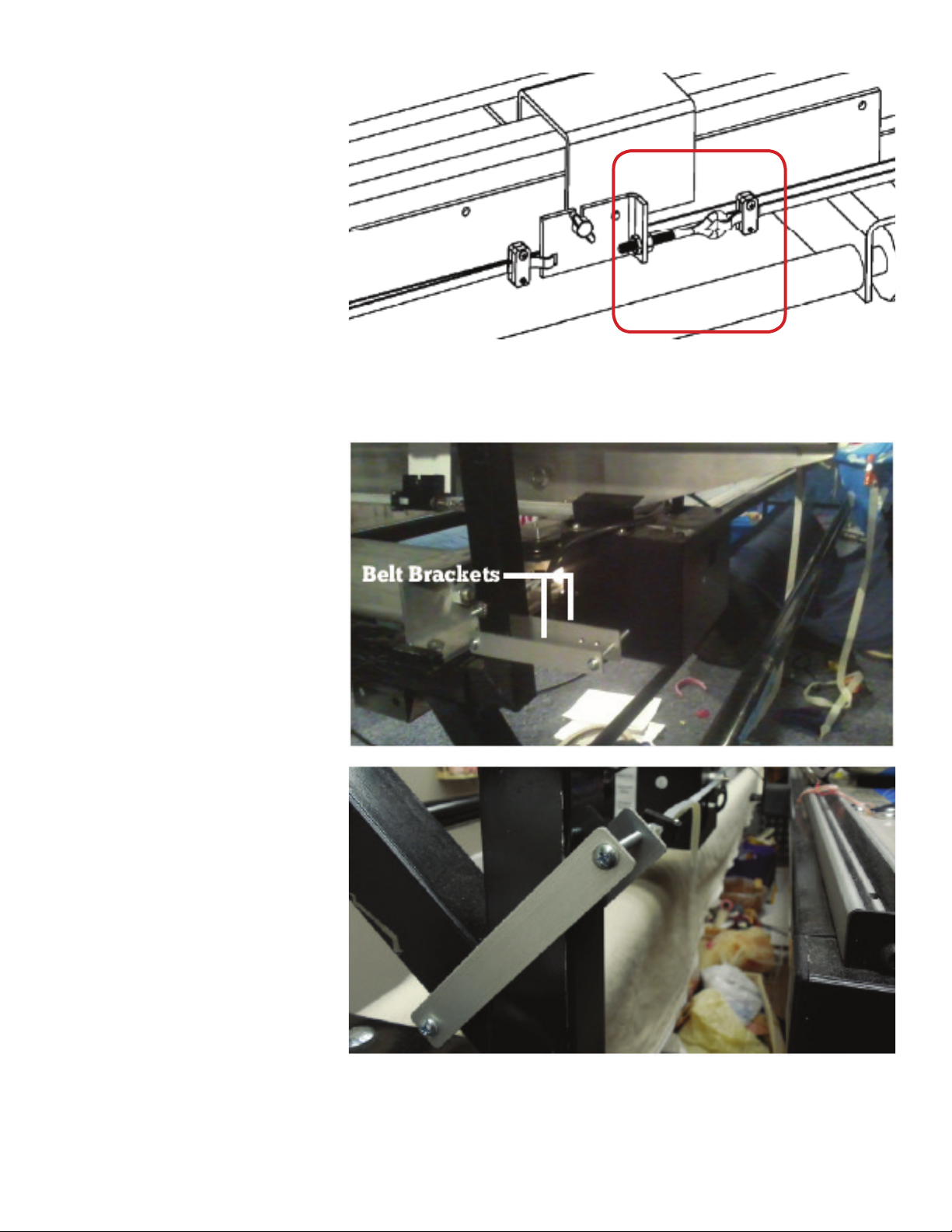

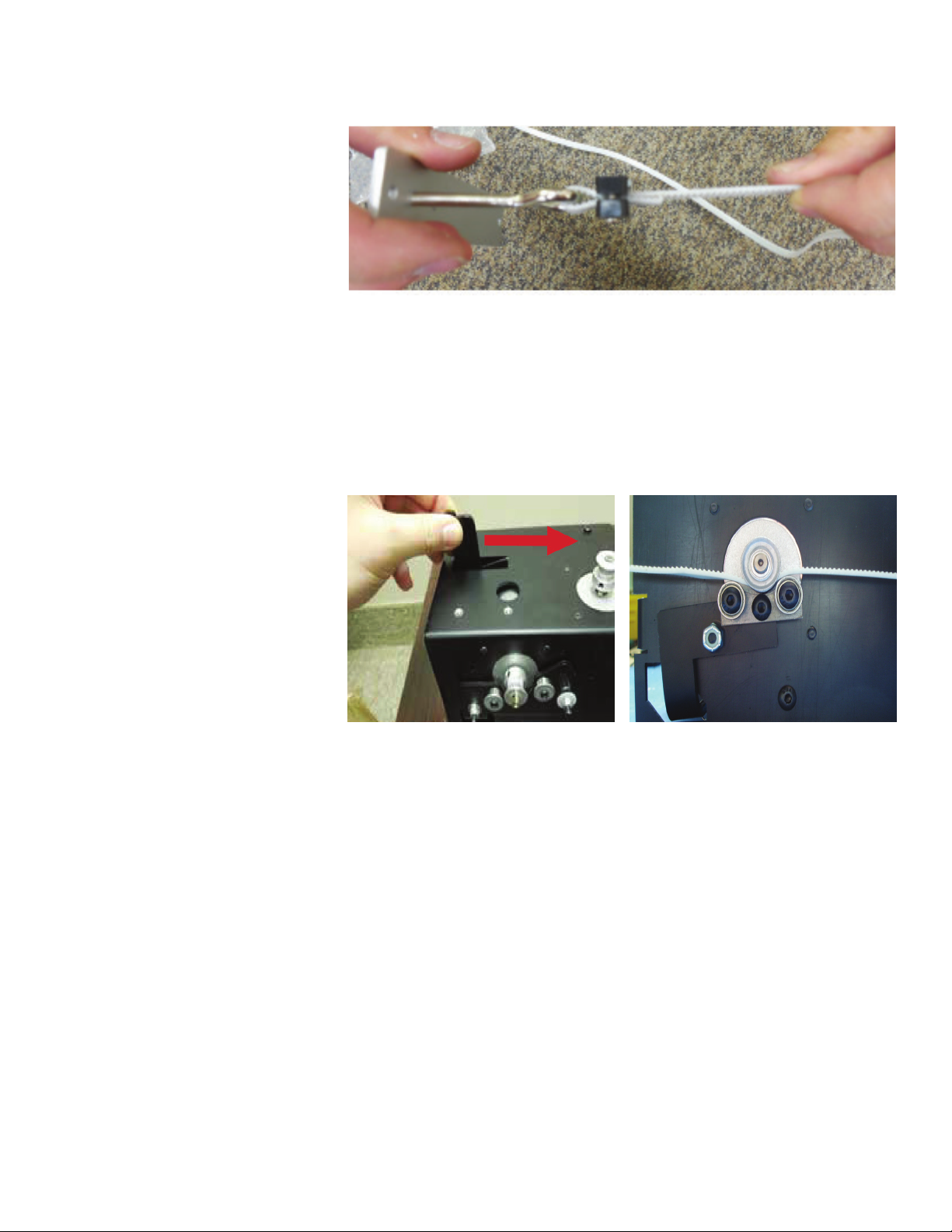

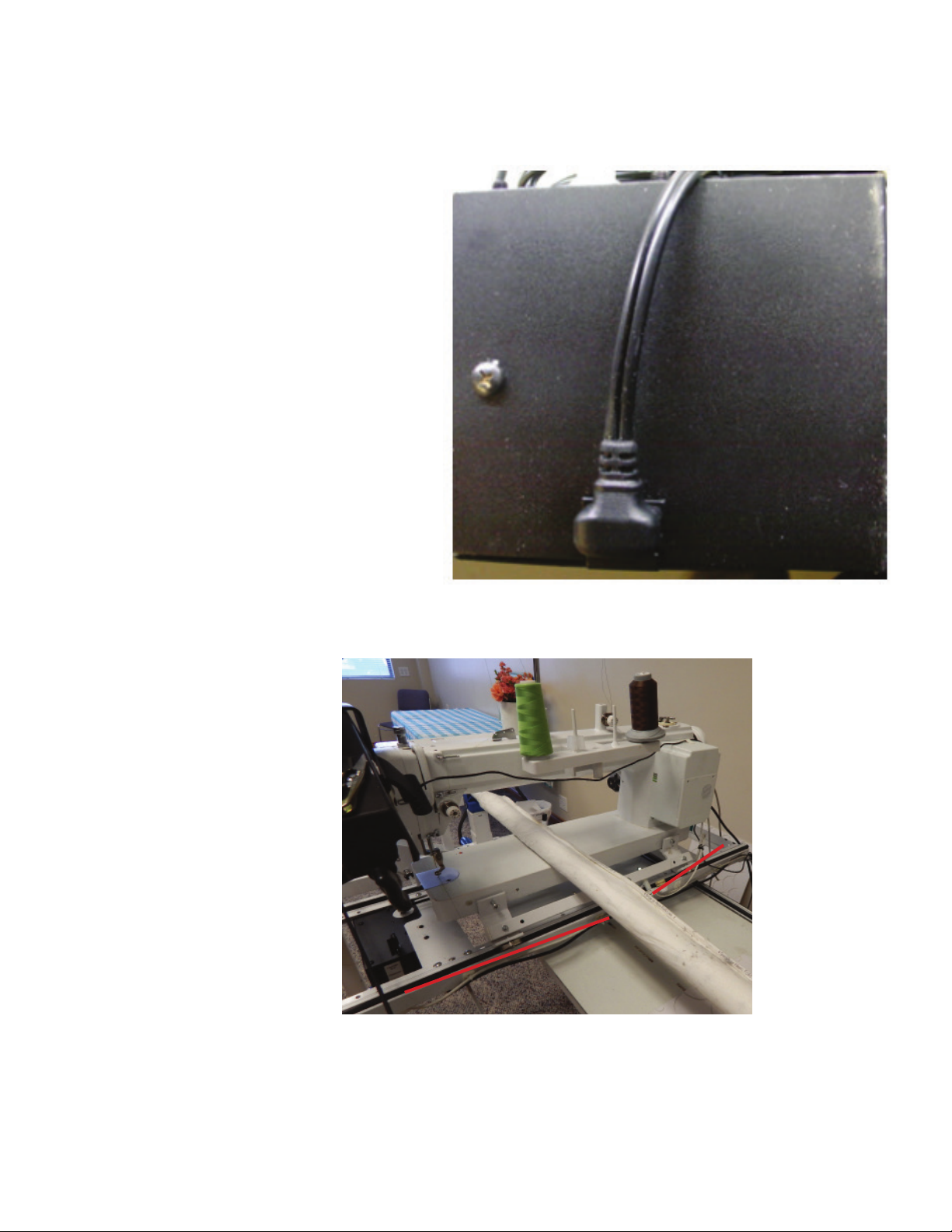

Install the White Belt (Bag X10 and Bag X1)

1ere are many dierent

options to mount the

clamp brackets to the

frame.

e brackets must be

mounted in a way that

the eye bolts are in line

with the x-axis pulley on

the motor.

Displayed are two

options for mounting, but

options are not limited to

these two.