2

BA_BM_HS-200_EN_43-21.docx

Table of Contents

1Introduction.............................................................................................................................................................4

1.1 Legal Notice.................................................................................................................................................................................. 4

1.2 Illustrations .................................................................................................................................................................................. 4

2Symbols ...................................................................................................................................................................4

2.1 General Symbols .......................................................................................................................................................................... 4

2.2 Symbols in Safety Instructions...................................................................................................................................................... 5

3General ....................................................................................................................................................................6

3.1 Advantages................................................................................................................................................................................... 6

3.2 Applications.................................................................................................................................................................................. 6

3.3 Target Group and Previous Experience ........................................................................................................................................ 6

3.4 Requirements for the Operators.................................................................................................................................................. 6

3.5 Accident Prevention..................................................................................................................................................................... 7

3.6 General Safety Regulations .......................................................................................................................................................... 7

3.7 Standard Equipment .................................................................................................................................................................... 7

3.8 Options and Accessories .............................................................................................................................................................. 7

4Safety.......................................................................................................................................................................8

4.1 Basic Safety Instructions............................................................................................................................................................... 8

4.2 Application Area and Intended Use.............................................................................................................................................. 8

4.3 Improper Use ............................................................................................................................................................................... 8

4.4 Consequences in Case of Disregard.............................................................................................................................................. 9

4.5 Conversions and Modifications of the Lift Tables......................................................................................................................... 9

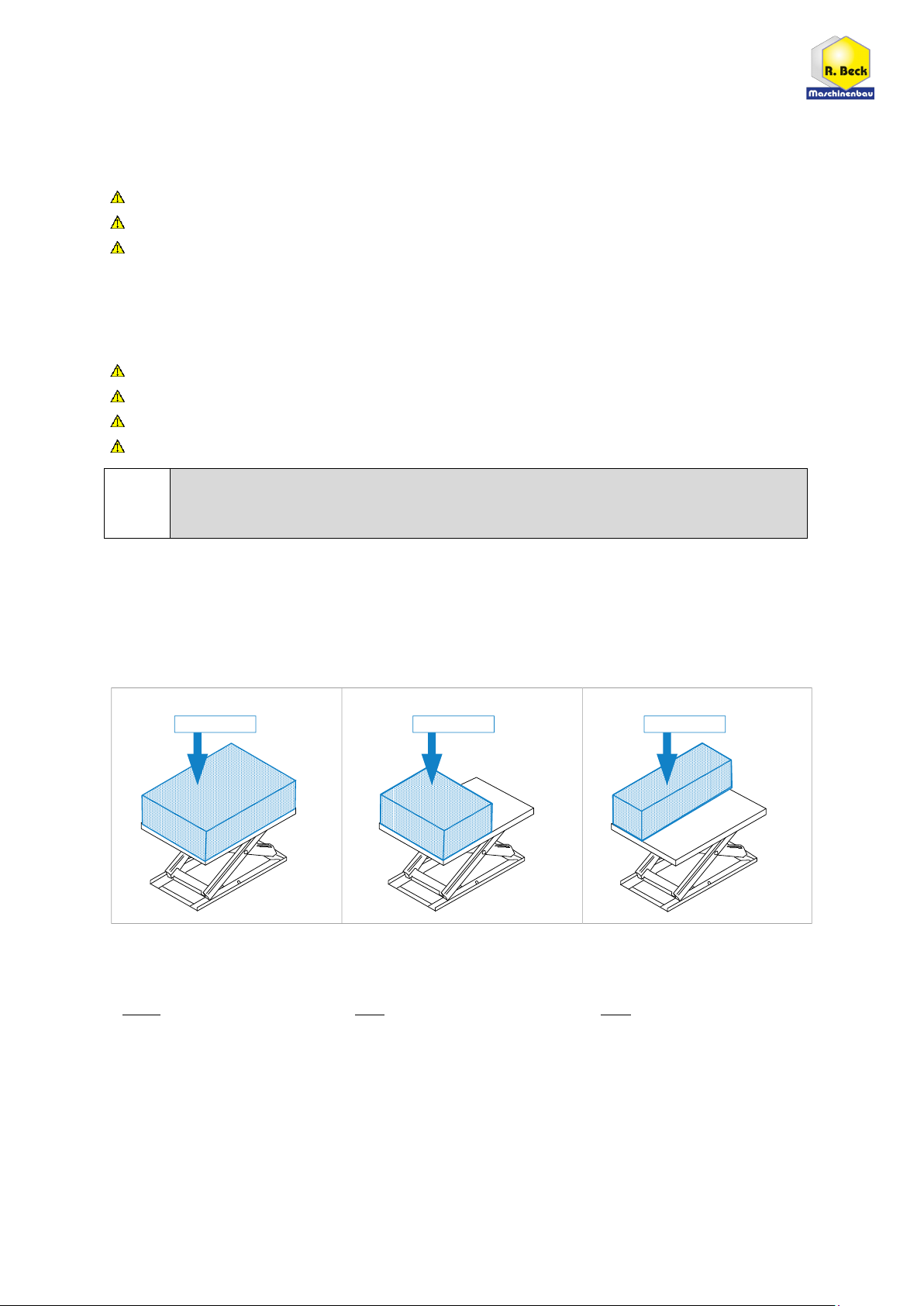

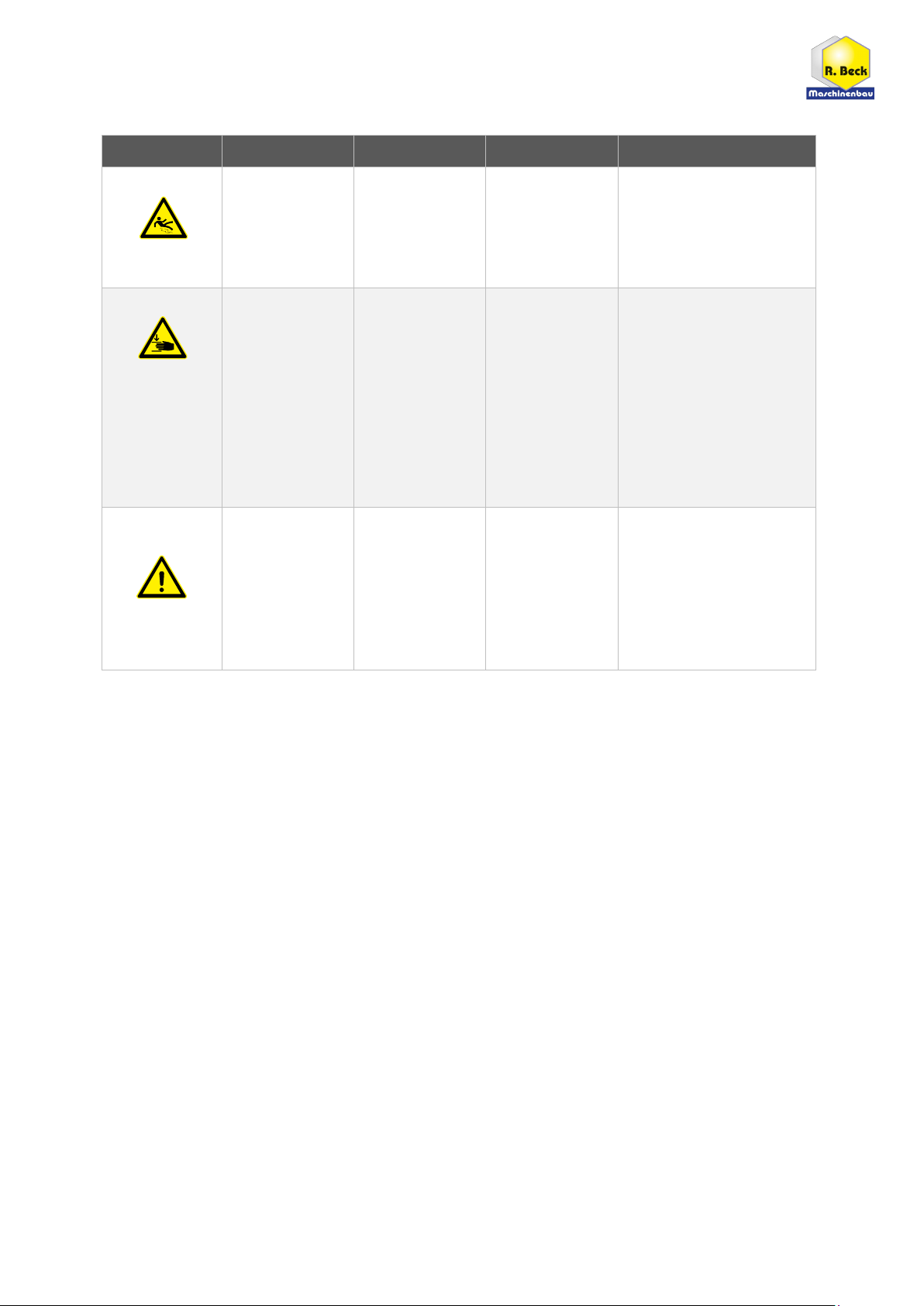

4.6 Load Distribution and Influence on the Nominal Load................................................................................................................. 9

4.7 Hazardous Areas ........................................................................................................................................................................ 10

4.8 Residual Risks............................................................................................................................................................................. 11

4.9 Observe the Environmental Protection Regulations .................................................................................................................. 11

4.10 Organisational Measures ........................................................................................................................................................... 12

4.11 Personnel Selection and Qualification - Basic Duties.................................................................................................................. 12

5Technical Specifications.........................................................................................................................................13

5.1 Manufacturer and Nameplate.................................................................................................................................................... 13

6Transport to the Installation Site...........................................................................................................................14

6.1 Unloading the Lift Table ............................................................................................................................................................. 14

6.2 Requirements for the Installation Site ....................................................................................................................................... 15

6.3 Temporary Storage..................................................................................................................................................................... 15

6.3.1 Short Term Storage ......................................................................................................................................................... 15

6.3.2 Long Term Storage .......................................................................................................................................................... 15

6.4 Lashing on a Transport Vehicle .................................................................................................................................................. 15

7Components and Controls.....................................................................................................................................16

8Installation and Commissioning.............................................................................................................................17

9Operation ..............................................................................................................................................................17

9.1 Load and Unload the Lift Table................................................................................................................................................... 17

9.2 Moving the Lift Table via Swivel Castors .................................................................................................................................... 17

9.3 Lifting and Lowering the Platform.............................................................................................................................................. 17

9.3.1 Height Adjustment .......................................................................................................................................................... 18