www.radialeng.com

© Radial Engineering Ltd. 1845 Kingsway Ave., Port Coquitlam, BC V3C 1S9, Canada

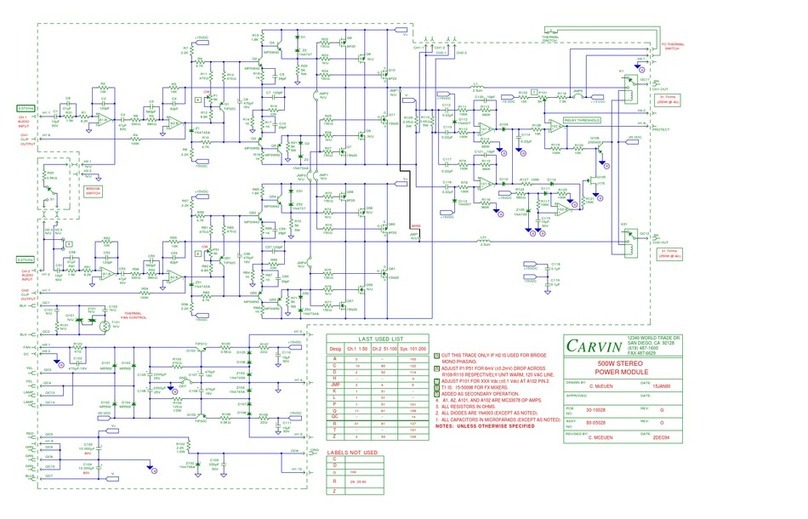

4. ¼" TS JACKS: Place J3 in the assigned designation. Make

sure the hole is facing outwards from the board, ip the board

over and solder two leads on opposite sides of the input jacks

to hold it in place. Then apply pressure while reheating the

leads so the jack becomes ush with the circuit board. Solder

the rest of the pins. You do not need to clip the wire leads for

the jacks. Repeat this process for J2.

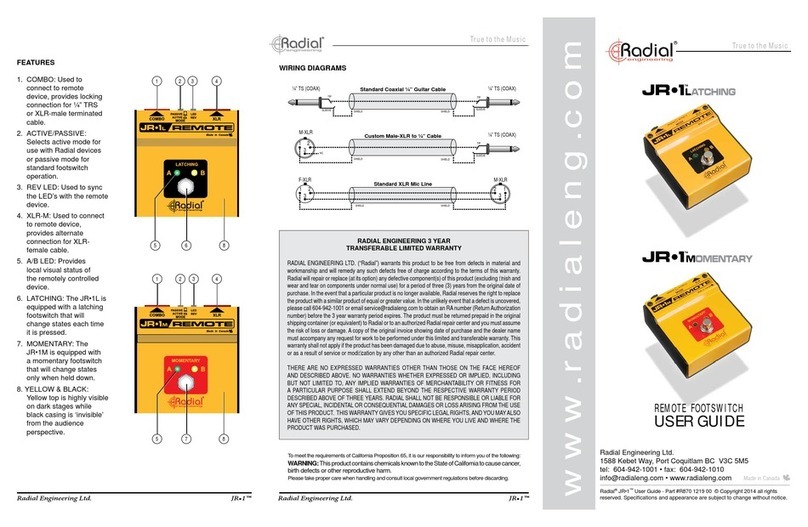

5. TRANSFORMER: Place the Jensen transformer into the T1

designation. Line up the dot on the transformer to the dot on

the circuit board, then ip it over and solder it in the same way

as the jacks. Solder two leads on opposite sides, then apply

pressure to the transformer while reheating the soldered leads

so it becomes ush with the board, then solder the rest of the

leads. Use the side cutters to clip the excess wire leads.

6. INSERTING THE XLR JACK: Position the male XLR connector

into the J1 designation so the pins are in the slots.

7. MOUNTING THE PCB: Before placing the PC board into the

metal insert, push the switches to the “IN” position to allow

more clearance and place the two orange washers on each

of the ¼" jacks. Now you can position the PC board in place.

Using the appropriate hex driver, drive in three of the 3/16"

screws to attach the PC board to the metal.

8. ATTACHING THE XLR JACK: Slide the XLR jack up so it

hangs slightly over the edge of the circuit board. Attach the

connector using the remaining two 3/16" screws. Be careful not

to overtighten them as you can damage the threading on the

XLR. To solder the pins into the slots, ip the EDU-DI upside

down and access the PC board by the hole in the bottom of the

metal. Heat up the pin rst and then apply a fair amount of solder. Repeat this for each pin.

9. SECURING THE TS HEX-NUTS: Insert the two metal hex-nuts into the two plastic black washers so the rounded

sides are facing outwards, then using your hands gently screw these into the jacks. Once they are positioned, you

can use the 7/16th nutdriver to tighten these (just past the tightness you can do with your ngers).

10. SWITCH BUTTONS: Attach the beige button caps to the two switches. Align the cap so that the square lines up, then

push it in rmly with either your ngers or a blunt object such as the end of screwdriver.

11. ASSEMBLY: Slide the metal insert into the metal wrapper. Ensure that the side of the

wrapper that says “LOW-Z OUT” is on the same side as the XLR, and that the side

that says “INPUT and “THRU” corresponds with the two jacks. Drive in two of the

¼" screws with the appropriate hex driver. Flip the EDU-DI over, and drive in the

remaining two screws.

12. NEOPRENE PAD: Remove the white backing from the Neoprene non-slip

pad then apply it to the bottom of the EDU-DI, to prevent it from sliding

around on a stage or studio oor.

13. TEST: Test the EDU-DI by plugging in an instrument into the ¼" input

and the XLR output to a PA system or microphone preamp and begin

playing. Activate the PAD switch to hear the attenuation work correctly.

Basic Instructions (Continued):

T1

S1

R1

C1

J1

J3

S2

R5

C2

R2

R3

R4

J2

Line up the dot on

the transformer

to the dot on the

circuit board.