SERIES AJ

4

EXPLANATION & USE OF

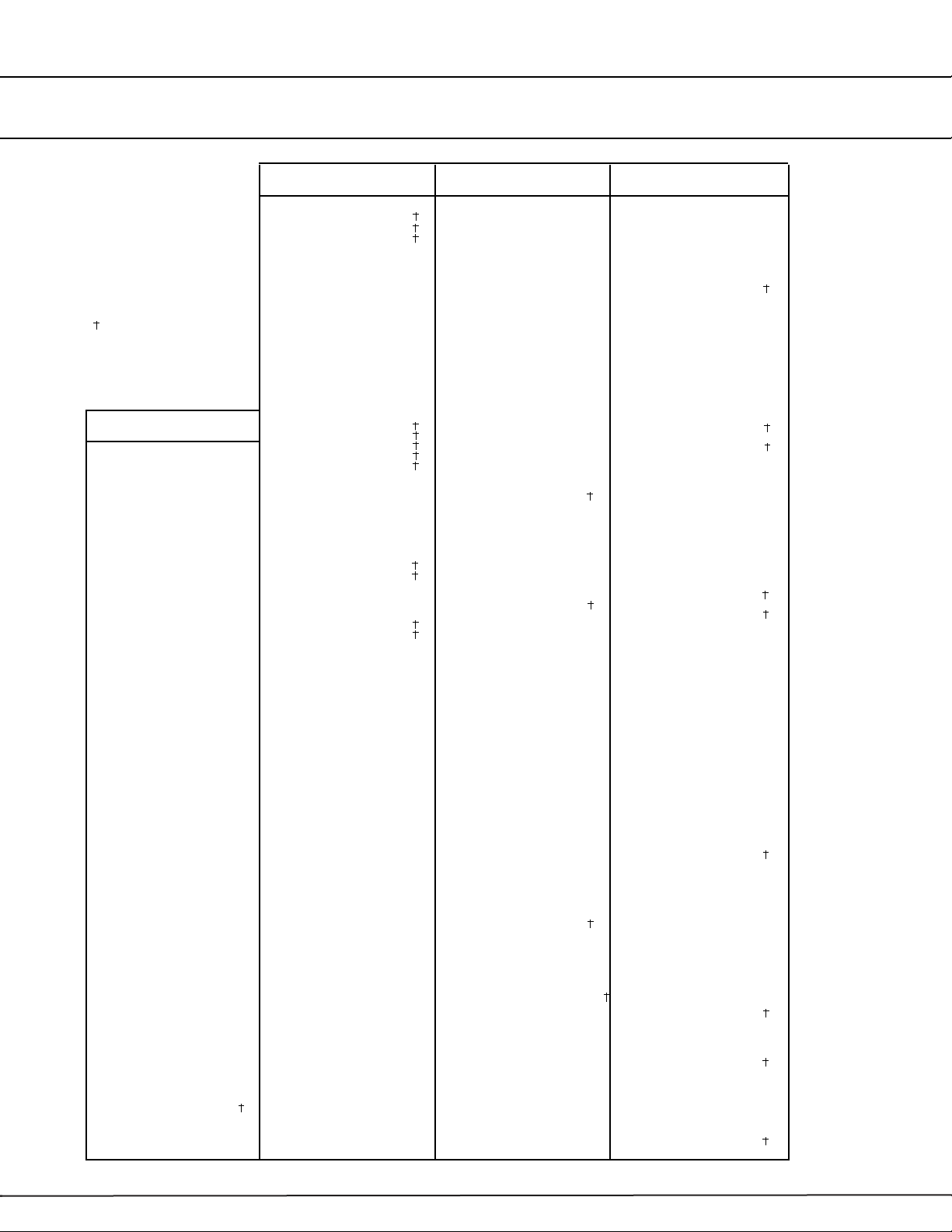

RATINGS & SERVICE FACTORS

Mechanical ratings and service factor FM

hour of operation.

used instead of Fm.

refer to application engineering.

application engineering.

Thermal ratings and service factors

Double Reduction Units

General

250

500

875

1160

1450

1750

2400

3500

280-610

730

860

280-610

730

860

280-610

730

860

280-610

730

860

280-610

730

860

280-610

730

860

280-610

730

860

280-610

730

860

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.46

1.44

1.46

1.46

1.38

1.46

1.46

1.34

1.41

1.46

1.30

1.37

1.46

1.28

1.34

1.46

1.26

1.32

1.46

1.22

1.30

1.46

1.13

1.24

1.72

1.52

1.72

1.72

1.56

1.72

1.72

1.47

1.60

1.72

1.43

1.54

1.72

1.39

1.50

1.72

1.36

1.46

1.72

1.30

1.42

1.72

1.23

1.34

1.96

1.92

1.96

1.96

1.75

1.96

1.96

1.64

1.79

1.96

1.56

1.72

1.96

1.52

1.66

1.96

1.47

1.61

1.96

1.39

1.55

1.96

1.30

1.45

2.32

2.26

2.32

2.32

2.02

2.32

2.32

1.84

2.07

2.32

1.75

1.96

2.32

1.69

1.88

2.32

1.63

1.81

2.32

1.53

1.75

2.32

1.41

1.61

2.86

2.75

2.86

2.86

2.38

2.86

2.86

2.16

2.45

2.86

2.05

2.32

2.86

1.97

2.21

2.86

1.89

2.14

2.86

1.75

2.03

2.86

1.58

1.85

Input

shaft

speed

Unit

>60 >50-60 >40-50 >30-40 >20-30 >20

% Running time per hour

Table 4. Thermal service factor Fd

0 to 100

>100 to 200

>200 to 300

>300 to 400

>400 to 500

>500 to 600

>600 to 700

>700

Output

Speed

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

DEF

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

KMN

Refer to

Engineering

PST

Mounting Position (See pages 9 and 10)

Table 3. Thermal service factor Fp (Single Reduction units)

temperature oF

Factor Ft

-20 020 40 60 68 80 100 120

1.64 1.50 1.36 1.22 1.07 1.00 0.92 0.77 0.63

Table 2. Thermal service factor Ft

Prime mover

or

internal

engine

internal

engine

Duration of

service hrs

Under 3

3 to 10

Over 10

Under 3

3 to 10

Over 10

Under 3

3 to 10

Over 10

Table 1. Mechanical service factor Fm

0.80

1.00

1.25

1.00

1.25

1.50

1.25

1.50

1.75

Uniform

0.80

1.00

1.25

1.00

1.25

1.50

1.25

1.50

1.75

Moderate

Shock

0.80

1.00

1.25

1.00

1.25

1.50

1.25

1.50

1.75

Shock