12. Slip one coil over the free end of the armature and then slip the second coil

off the armature and stylus. All parts before re-assembling should be thoroughly

cleaned and freed from all traces of dust or dirt and metal filings, etc. Use a brush to

remove foreign matter from the parts. Avoid the use of liquid cleaners as they often

induce corrosion.

The re-assembly should be a reversal of the operation just described.

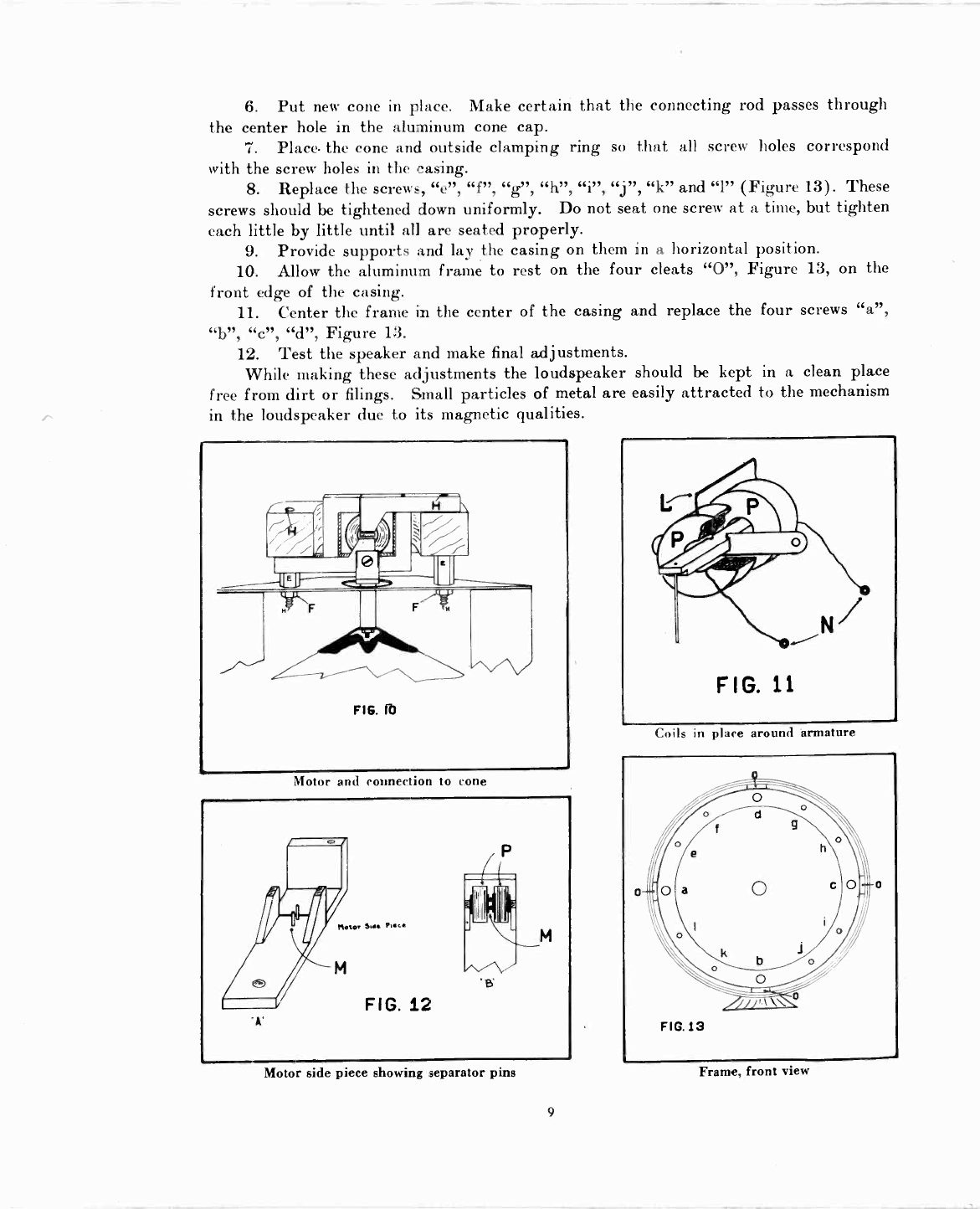

1. Place the coils "P"-"P", Figure 11, in proper position around the armature.

The small length of wire connecting the two coils in series should be at the outside of

each coil when assembled, "L", Figure 11.

2. Place the coils with armature in position onone of the motor side pieces, Figure

12. Place the other motor side pieces in place and screw the assembly together by means

of the screw. In making this assembly make certain that the small pins "M", Figure 12,

projecting from the inner side of the motor side piece, separate the two field coils as shown

in "B", Figure 12.

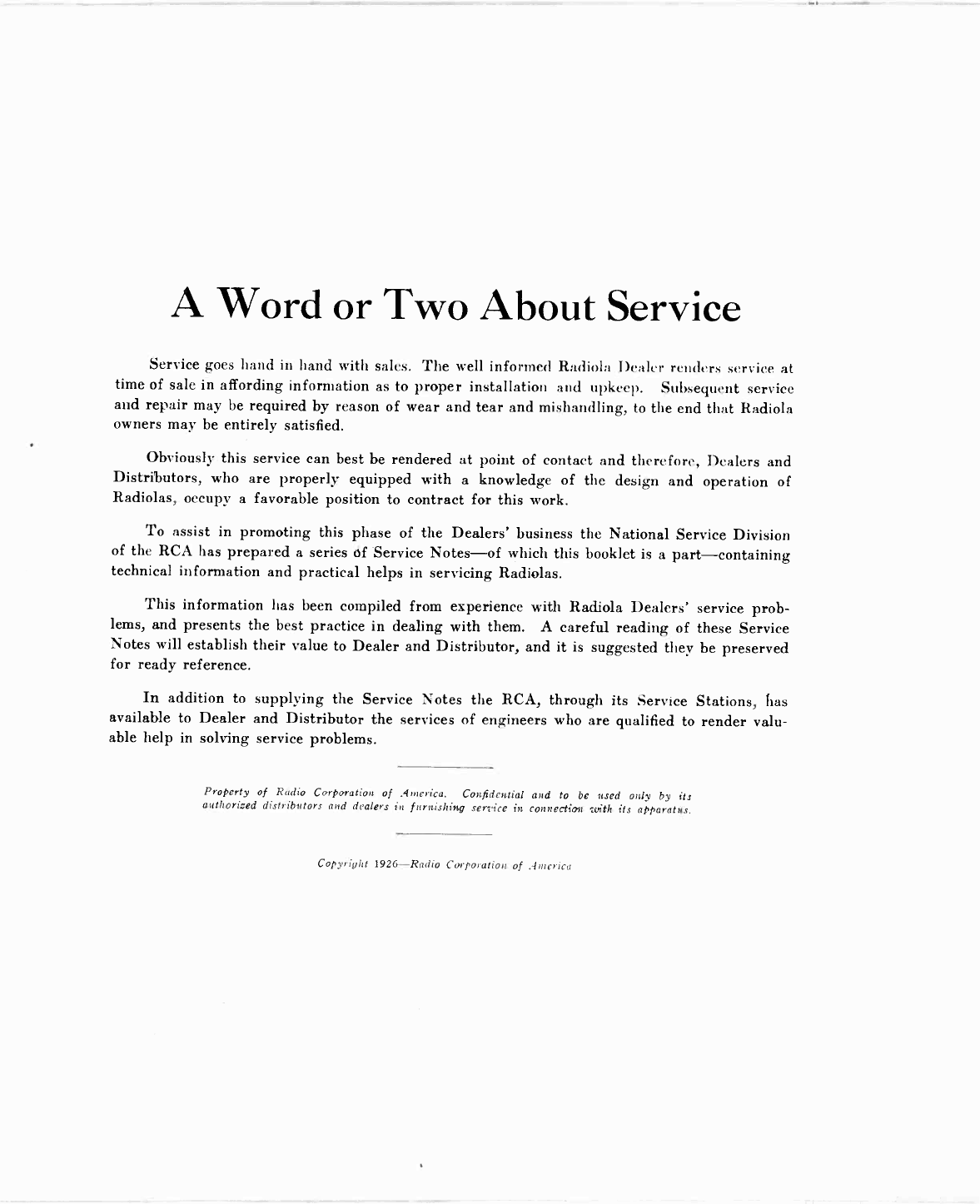

3. Place the thrust lever in position and screw it in place "d", Figure 2, but, do

not solder to the stylus at this time.

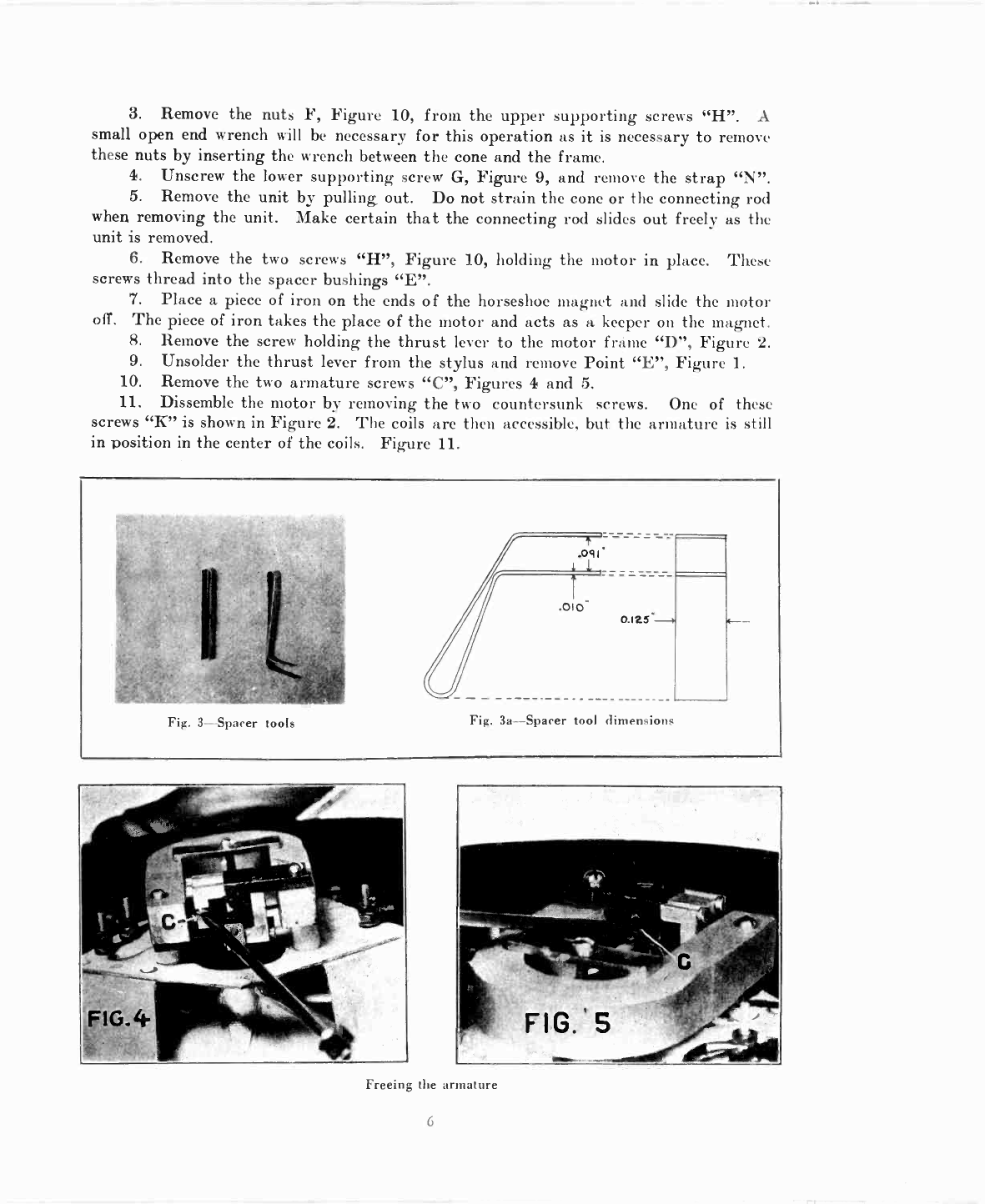

4. Replace the armature screws "C", Figures 4 and 5, but do not seat them firmly.

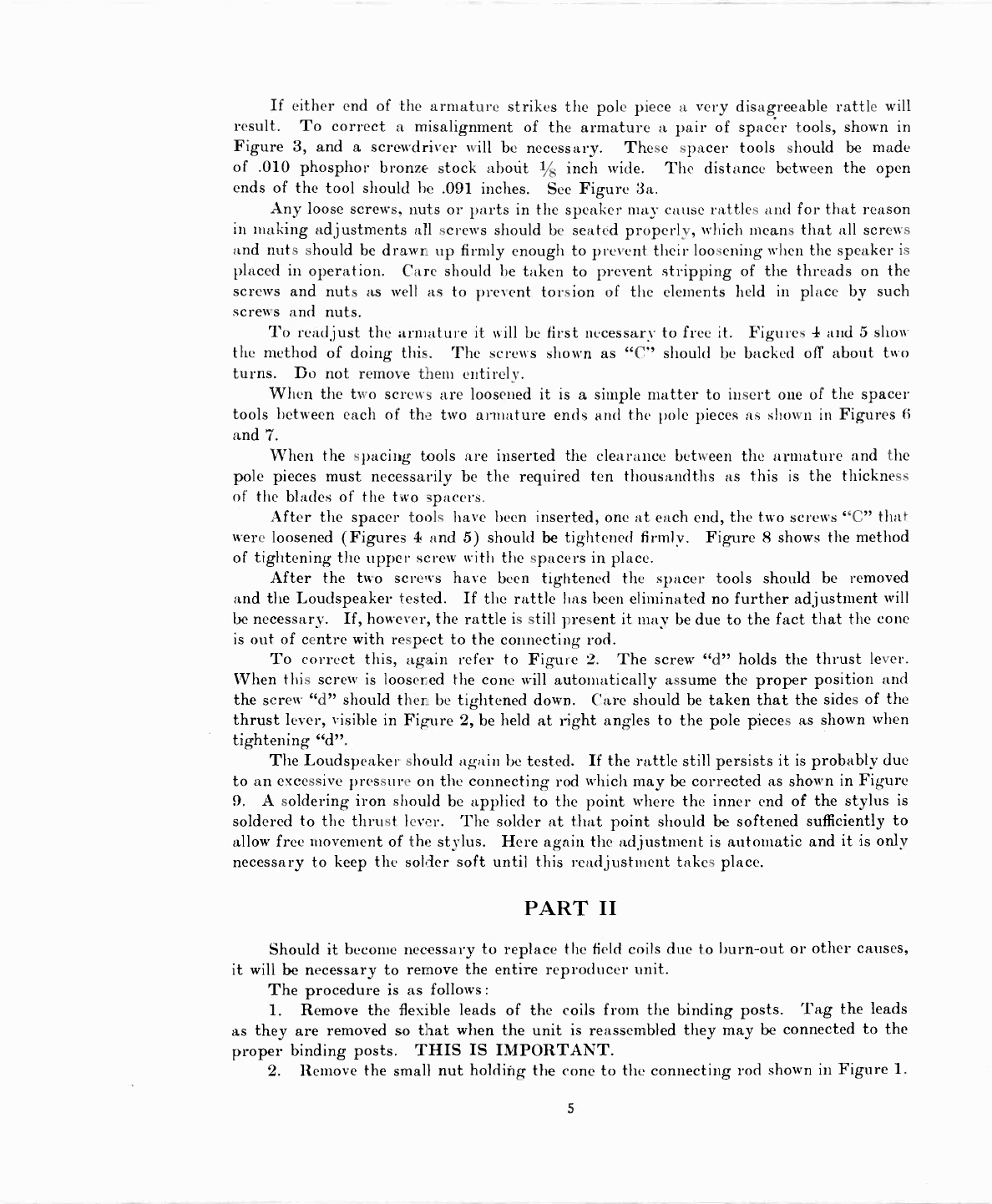

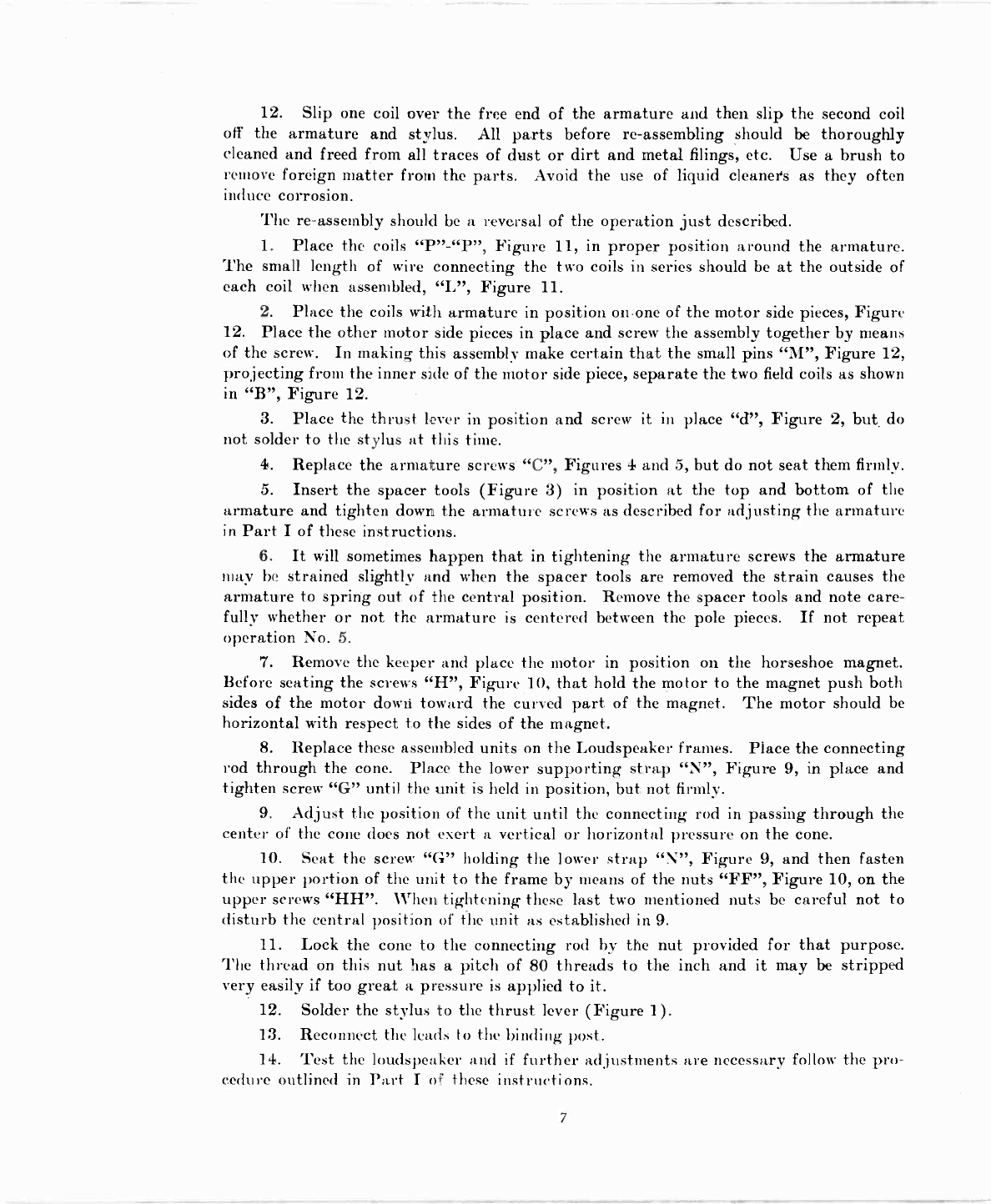

5. Insert the spacer tools (Figure 3) in position at the top and bottom of the

armature and tighten down the armature screws as described for adjusting the armature

in Part I of these instructions.

6. It will sometimes happen that in tightening the armature screws the armature

may be strained slightly and when the spacer tools are removed the strain causes the

armature to spring out of the central position. Remove the spacer tools and note care-

fully whether or not the armature is centered between the pole pieces. If not repeat

operation No. 5.

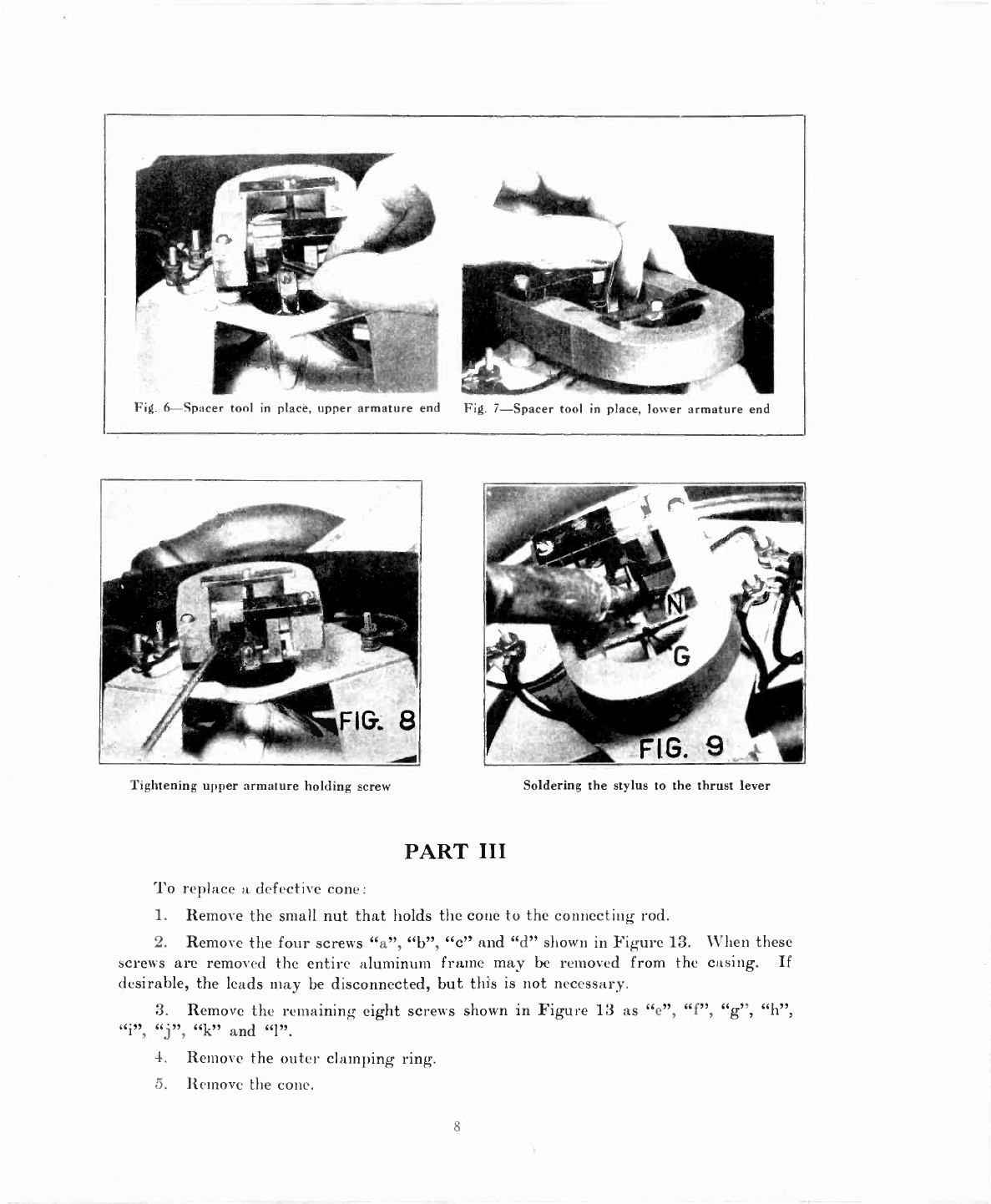

7. Remove the keeper and place the motor in position on the horseshoe magnet.

Before seating the screws "H", Figure 10, that hold the motor to the magnet push both

sides of the motor down toward the curved part of the magnet. The motor should be

horizontal with respect to the sides of the magnet.

8. Replace these assembled units on the Loudspeaker frames. Place the connecting

rod through the cone. Place the lower supporting strap "N", Figure 9, in place and

tighten screw "G" until the unit is held in position, but not firmly.

9. Adjust the position of the unit until the connecting rod in passing through the

center of the cone does not exert a vertical or horizontal pressure on the cone.

10. Seat the screw "G" holding the lower strap "N", Figure 9, and then fasten

the upper portion of the unit to the frame by means of the nuts "FF", Figure 10, on the

upper screws "HH". When tightening these last two mentioned nuts be careful not to

disturb the central position of the unit as established in 9.

11. Lock the cone to the connecting rod by the nut provided for that purpose.

The thread on this nut has a pitch of 80 threads to the inch and it may be stripped

very easily if too great a pressure is applied to it.

12. Solder the stylus to the thrust lever (Figure 1).

13. Reconnect the leads to the binding post.

14. Test the loudspeaker and if further adjustments are necessary follow the pro-

cedure outlined in Part I of these instructions.

7

www.americanradiohistory.com