mod. BIBULLDOG ADV

© Raimondi S.p.a.

Page 2/44-0

machines & tools for the tile & stone professional

Index

TABLE OF CONTENTS

CHAPTER 1 INTRODUCTION

1.1 DECLARATION OF CONFORMITY ________________________________________________________________________ 3/44-1

1.2 TESTING, WARRANTY AND RESPONSIBILITY ______________________________________________________________ 4/44-1

1.3 ENVIRONMENTAL CONDITIONS __________________________________________________________________________ 4/44-1

1.4 INTERVENTION REQUEST AND TECHNICAL SERVICE _______________________________________________________ 5/44-1

1.5 SPARE PARTS ORDERS _________________________________________________________________________________ 5/44-1

1.6 MARKING _____________________________________________________________________________________________ 5/44-1

CHAPTER 2 SAFETY RULES

2.1 SAFETY GENERAL RULES _______________________________________________________________________________ 6/44-2

2.2 DEFINITION OF SAFETY-RELATED TERMS _________________________________________________________________ 7/44-2

2.3 CORRECT USE OF THE MACHINE ________________________________________________________________________ 7/44-2

2.4 CHARACTERISTICS OF THE MACHINE ____________________________________________________________________ 7/44-2

2.5 DESCRIPTION OF MACHINE GROUPS ____________________________________________________________________ 9/44-2

2.6 POSITION OF THE OPERATOR __________________________________________________________________________ 10/44-2

2.7 SAFETY DEVICES _____________________________________________________________________________________ 10/44-2

2.8 ACCESSORIES OF THE MACHINE _______________________________________________________________________ 11/44-2

2.9 NOISE _______________________________________________________________________________________________ 11/44-2

2.10 VIBRATIONS __________________________________________________________________________________________ 12/44-2

2.11 DEMOLITION AND DISPOSAL ___________________________________________________________________________ 14/44-2

2.12 CE MANUFACTURER'S DECLARATION ___________________________________________________________________ 14/44-2

CHAPTER 3 HANDLING, INSTALLATION, ADJUSTMENTS

3.1 PACKING TRANSPORT _________________________________________________________________________________ 15/44-3

3.2 MANUAL HANDLING ___________________________________________________________________________________ 15/44-3

3.3 POWER SUPPLY _______________________________________________________________________________________ 16/44-3

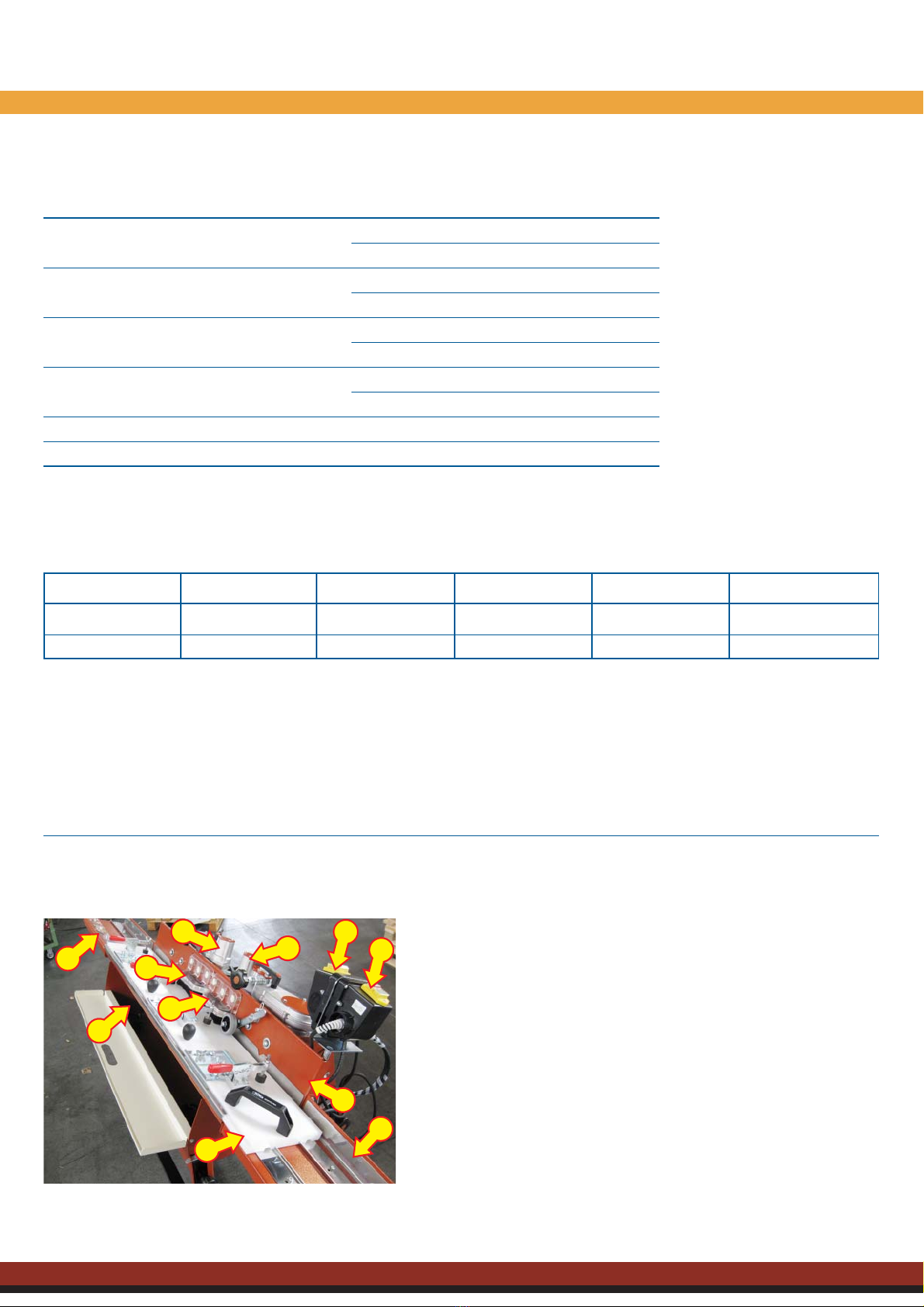

3.4 ASSEMBLY OF THE MACHINE ___________________________________________________________________________ 17/44-3

3.4.1 TANK FILLING ________________________________________________________________________________________ 18/44-3

CHAPTER 4 USE OFTHE COMMANDS

4.1 ADJUSTING THE GRINDING WHEEL FOR HALF-ROUND SHAPING __________________________________________ 19/44-4

4.2 ADJUSTING THE 45° GRINDING WHEEL FOR JOLLY CUTS/BEVELLING ______________________________________ 20/44-4

4.3 BLOCKING OF MATERIAL ______________________________________________________________________________ 21/44-4

4.4 COMPLY WITH THE FOLLOWING WARNINGS FOR ALL PROFILING TYPES ____________________________________ 22/44-4

4.5 HALF-BULLNOSE SHAPING ____________________________________________________________________________ 23/44-4

4.6 PERFORMING JOLLY CUTS (MITERING 45°) AND BEVELLING _______________________________________________ 24/44-4

4.7 GRINDING EDGES ____________________________________________________________________________________ 24/44-4

4.8 SEQUENCE OF WHEELS _______________________________________________________________________________ 26/44-4

4.9 COMBINATION OF DIFFERENT MACHINES _______________________________________________________________ 28/44-4

CHAPTER 5 MAINTENANCE INTERVENTIONS

5.1 CLEANING THE MACHINE ______________________________________________________________________________ 29/44-5

5.2 TANK EMPTYING AND CLEANING _______________________________________________________________________ 29/44-5

5.3 SLIDING DEVICE REPLACEMENT _______________________________________________________________________ 30/44-5

5.3.1 ADJUSTING THE SLIDING DEVICE ______________________________________________________________________ 30/44-5

5.4 REPLACING THE GRINDING WHEEL _____________________________________________________________________ 31/44-5

5.4.1 SHARPENING THE GRINDING WHEEL ___________________________________________________________________ 32/44-5

5.5 STARTER REPLACEMENT ______________________________________________________________________________ 32/44-5

5.6 RECYCLE PUMP REPLACEMENT ________________________________________________________________________ 33/44-5

5.7 STARTER OR THERMAL RELAY REPLACEMENT ___________________________________________________________ 34/44-5

CHAPTER 6 ACCESSORIES

6.1 ACCESSORIES ________________________________________________________________________________________ 35/44-6

6.2 SET-SQUARES ________________________________________________________________________________________ 35/44-6

6.3 TUBULAR JUNCTION __________________________________________________________________________________ 35/44-6

CHAPTER 7 DIAGNOSTICS

7.1 TROUBLE-SHOOTING _________________________________________________________________________________ 36/44-7

CHAPTER 8 SPARE PARTS AND ELECTRIC DIAGRAM

8.1 SPARE PARTS ________________________________________________________________________________________ 38/44-8

8.2 ELECTRIC DIAGRAMS _________________________________________________________________________________ 42/44-8