TURBORAM | Edition C - Revision 4

Instruction Manual | 10

Baking with a programme

Proceed as follows to select a programme:

1 - Press (NPROG) once;

2 - Use ( ) or ( ) to search for the desired pro-

gramme;

3 - Once you find the desired programme, press (OK)

once.

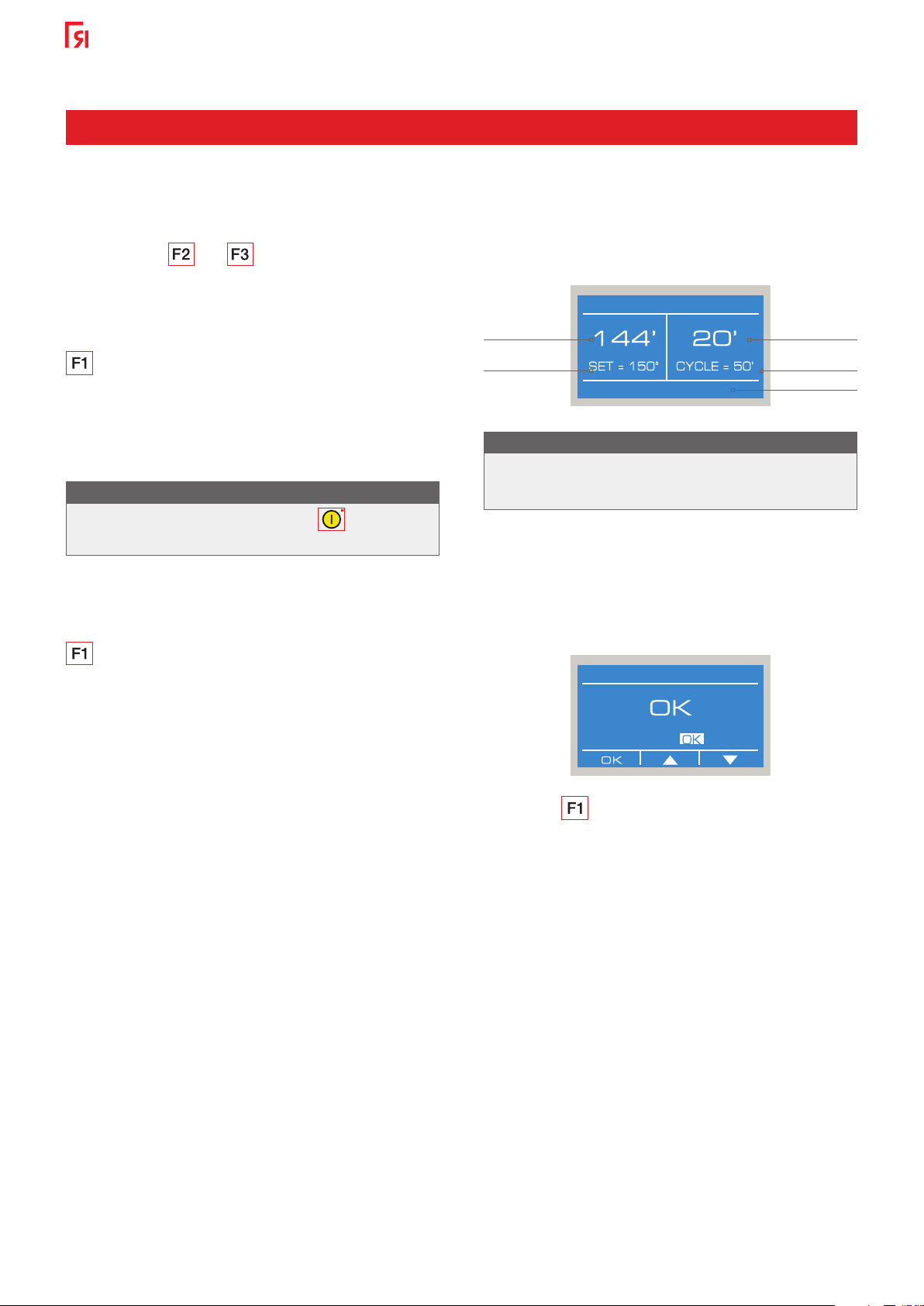

Once the programme appears on the display, proceed as fol-

lows to start the baking cycle:

1 - Press the button once.

The oven will pre-heat until it reaches the selected tempera-

ture.

Once the oven reaches the selected temperature, an acoustic

signal will be heard and the message OPEN and LOAD will

show up on the display intermittently.

Open the oven, load the product to be baked and close the

oven door.

As the oven door is closed the message BAKING IN COURSE

will show up on the display intermittently.

During this stage, steam injection and remaining baking time

will be done automatically.

Once the programmed baking time is over, an acoustic signal

will be heard and the message OPEN TO STOP will show up

on the display intermittently.

Open the oven door and unload the baked produce.

If the oven door is kept open for more than 10 seconds when

the product is unloaded, the oven will remain inactive until a

new baking cycle is started.

EDITING PROGRAMMES DURING THE BAKING CYCLE

Proceed as follows to alter the temperature or baking time

during a baking cycle (while the message BAKING IN COURSE

appears intermittently on the display):

• Temperature

1 - Press the temperature button on the display once to see

the selected temperature.

2 - Use ( ) or ( ) to alter the temperature.

3 - Press (OK) to set the desired temperature.

• Baking time

1 - Press the time button on the display once to see the se-

lected baking time.

2 - Use ( ) or ( ) to alter the baking time.

3 - Press (OK) to set the desired baking time.

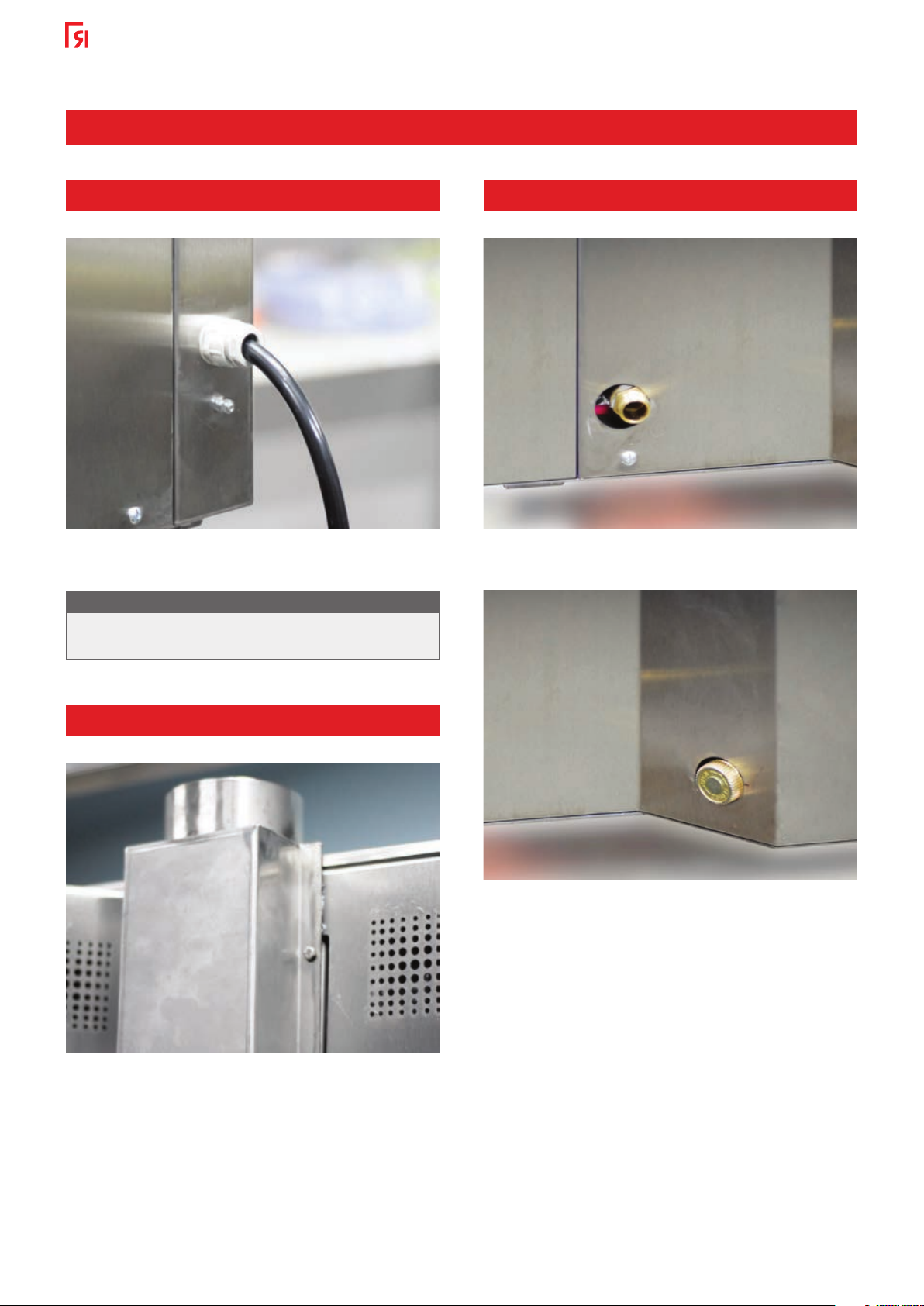

• Open or close the steam output valve manually

The steam output valve may be opened or closed by press-

ing the button.

If the LED of the button is turned off it means the valve is

closed. If the LED is on it means the valve is opened.

• Manual steam injection

The oven will inject steam automatically in the beginning of

the baking cycle (as mentioned previously). However, should

you need to inject more steam press the button once

and the control panel will inject steam.

If the operator realizes that baking time needs to be extend-

ed as the product is unloaded, he/she should close the oven

door within ten seconds and the oven will automatically add

minutes to the baking cycle.

Even when the oven is in standby mode in between baking

cycles, the turbines will continue functioning until the tem-

perature drops below 150ºC to allow the motors to cool

down.

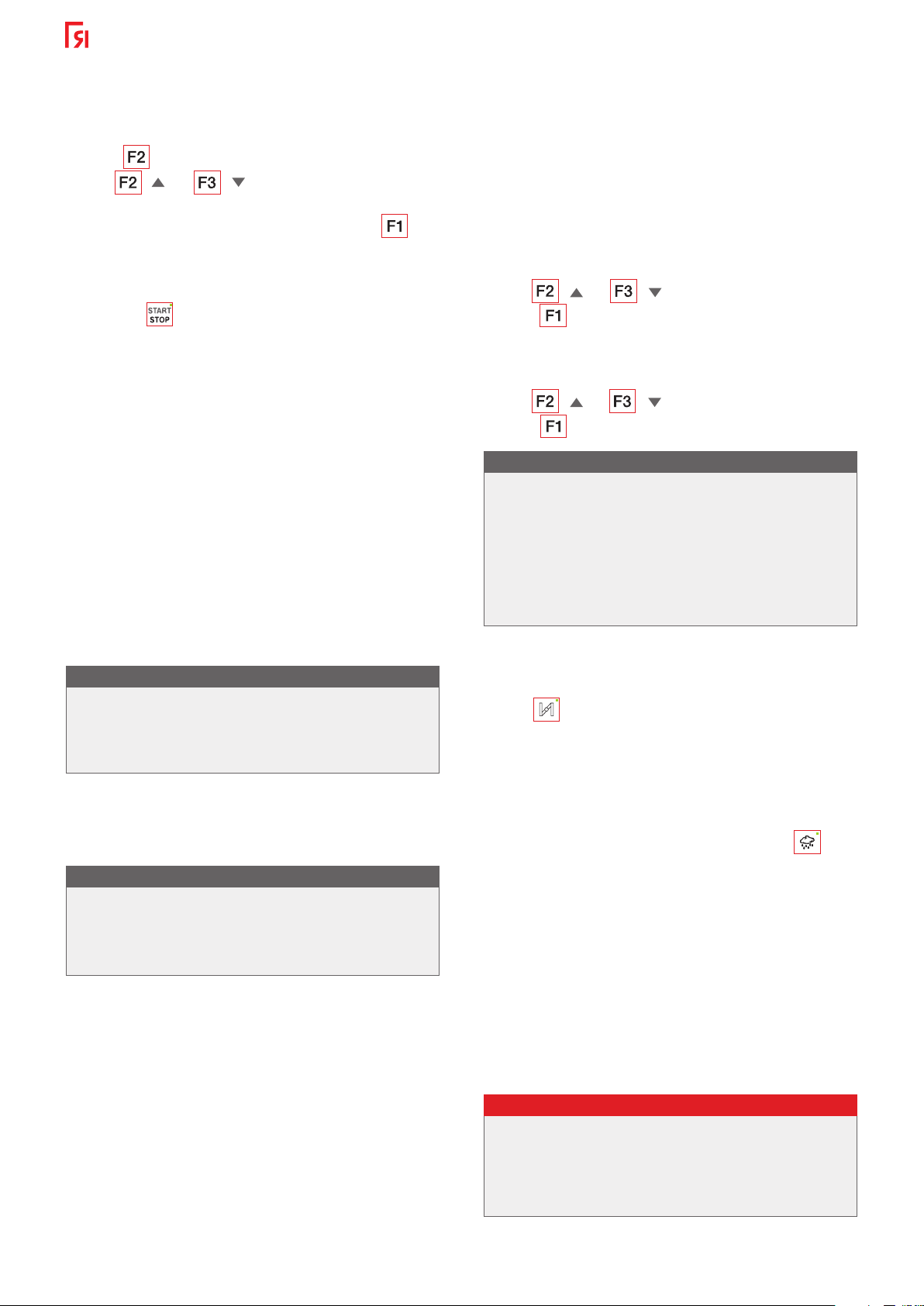

If the changes are made in the programme 0---Manual, they

will be immediately stored in that programme.

If the changes are made in a different programme (not

0---Manual), they will only be effective for that baking cycle

and will not be stored in the programme for future baking

cycles.

Important note

Baking of products with high alcohol content is strongly

disadvised due to potential danger of explosion and fire.

If reduced alcohol content products are used, the steam

valve must remain open throughout baking in order to

easily evaporate alcohol content.