WARNING INSTRUCTIONS

1. This equipment incorporates parts such as electrical

switches which tend to produce sparks. When located in a

service facility, the unit should be in a ventilated room or

enclosure provided for the purpose, or should be at least 18

inches or more above floor to minimize the risk of igniting

fuel vapors.

2. Eye and face protection is required and strongly

recommended: “Protective eye and face equipment is

required to be used where there is a reasonable probability

of injury that can be prevented by use of such equipment.”

OSHA1910.133 (a) Protective goggles, safety glasses, or a

face shield must be provided by the purchaser/user and

worn by the operator of the equipment. Make sure all eye

and face safety precautions are followed by the operator(s).

Keep bystanders out of the area.

3. Do not remove any safety equipment such as guards,

control switches or shut-off devices.

4. Make sure rotors are properly mounted and square

before starting the lathe. Check to make sure all parts are

secure.

5. Make sure the rotors are clean and mounted properly

before attaching lathe to the caliper.

6. Do not overload the lathe. Read and understand the lathe

capabilities prior to operation. Overloading the lathe can

shorten the lifespan of the unit, and could cause a failure

resulting in personal injury.

7. Check damaged parts carefully. Before further use of the

lathe, a guard or other part that is damaged should be

carefully checked. Immediately replace all damaged,

missing, or non-functional parts. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

operation. Guards and other parts that are damaged should

be properly repaired or replaced before lathe is used again.

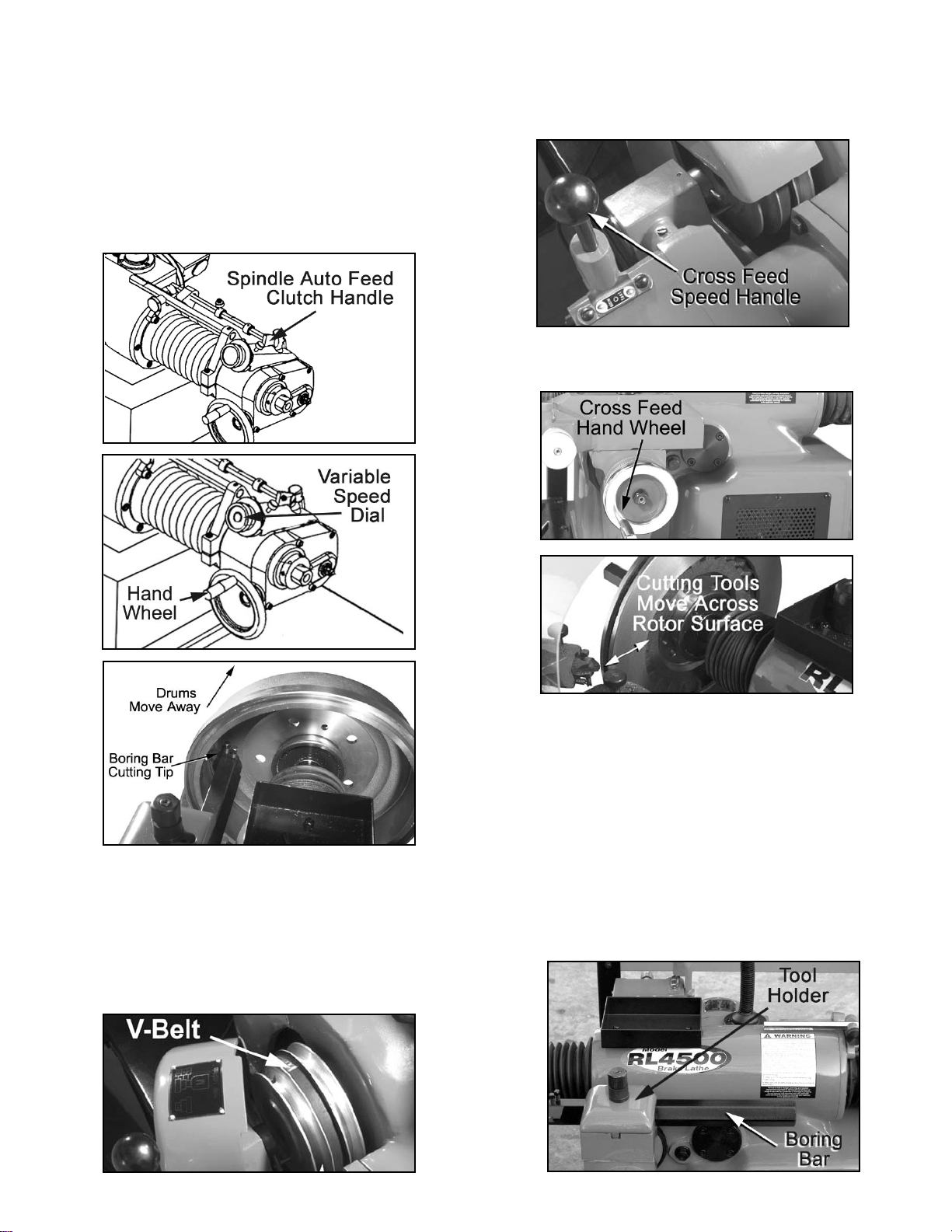

8. Always feed the blade or cutter into the work and against

the direction of rotation. Cutters and tool bits are designed

to begin the cut from near the center of the rotor to the outer

edge. Do not attempt to cut from the outside edge into the

center.

9. Never leave the brake lathe running unattended. Turn the

power off. Don’t leave the brake lathe until the power switch

is turned to the OFF position.

10. Never use compressed air to blow and clear chips.

Chips and dust may be driven between machined parts and

into bearings, causing undue wear. They may also contact

persons in the area causing personal injury.

BEFORE YOU BEGIN

Receiving:

The shipment should be thoroughly inspected as soon as it

is received. The signed bill of lading is acknowledgement by

the carrier of receipt in good condition of shipment covered

by your invoice. If any of the goods called for on this bill of

lading are shorted or damaged, do not accept them until the

carrier makes a notation on the freight bill of the shorted or

damaged goods. Do this for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or

damage is discovered after receipt and request the carrier

to make an inspection. If the carrier will not do so, prepare

a signed statement to the effect that you have notified the

carrier (on a specific date) and that the carrier has failed to

comply with your request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAM-AGE

AFTER YOU HAVE GIVEN THE CARRIER A CLEAR

RECEIPT. File your claim with the carrier promptly. Support

your claim with copies of the bill of lading, freight bill,

invoice, and photographs, if available. Our willingness to

assist in helping you process your claim does not make

Ranger Products responsible for collection of claims or

replacement of lost or damaged materials.

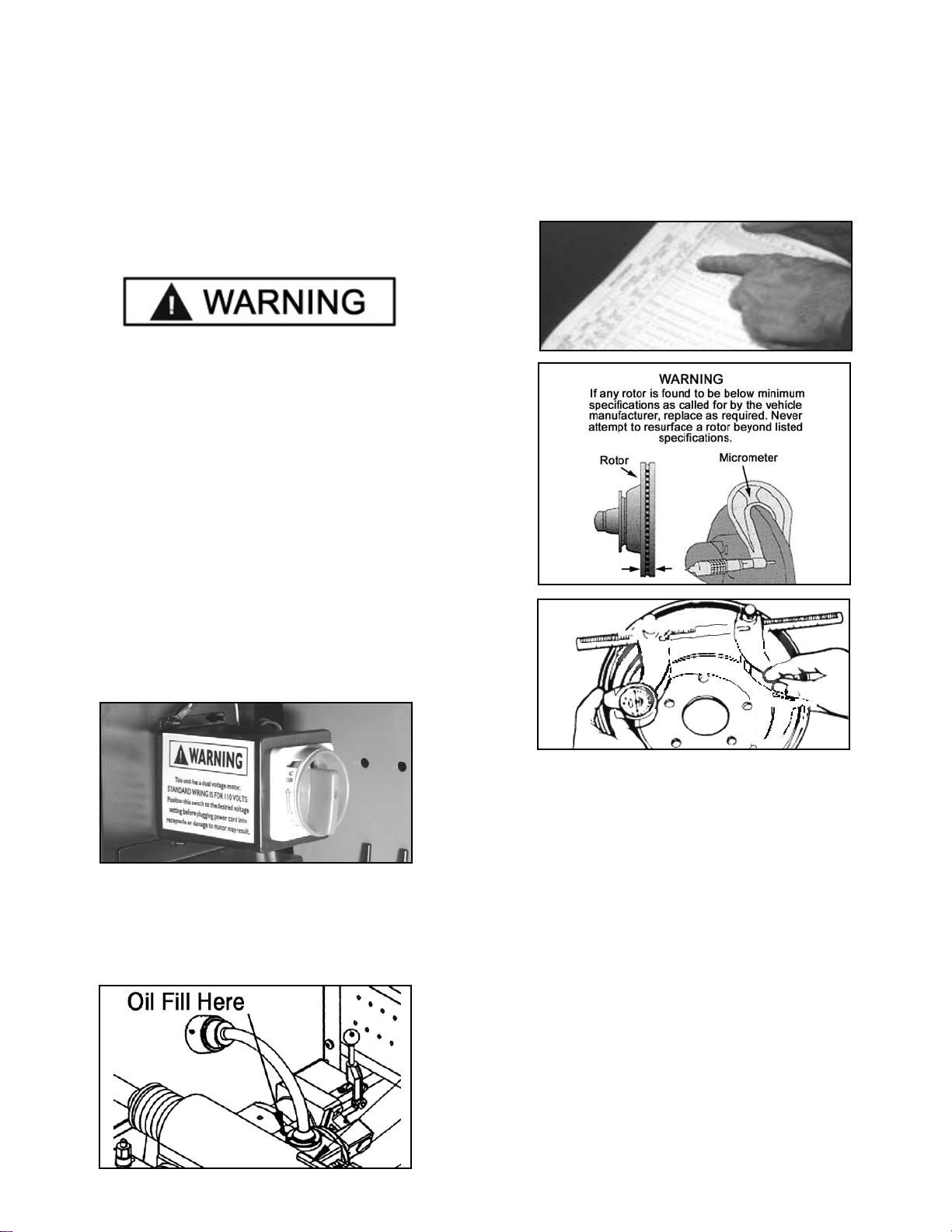

ELECTRICAL REQUIREMENTS

This unit requires power from a 15 amp 110 volt electrical

circuit. The lathe must be properly grounded to protect the

operator from shock. The RL4500 is equipped with an

approved power cord and 3-prong grounding-type plug.

Should an extension cord be required, be sure to use a

similar size power cord with 3-prong grounding plug and a

3-prong grounding receptacle properly rated to handle the

electrical requirement of this unit. Do not modify a cord or

plug to match a receptacle; have a qualified electrician

install an appropriate outlet to match the lathe

requirements. Repair or replace any worn or damaged

power cords immediately.

IMPORTANT NOTE

For 220 volt operation it will be necessary to replace the

110 volt 3-prong plug with an appropriate 220 volt 3-prong

plug with ground. After changing the plug, position the

voltage selector switch at the rear of the unit to the 220

setting. Verify that the lathe plug and grounding-type

receptacle match.

4