Instruction Manual

UBG –Round bale grapple –1 hydralic cylinder

UBG2C - Round bale grapple –2 hydralic cylinder

UBGS - Round bale grapple SMART

USBG –Square bale grapple

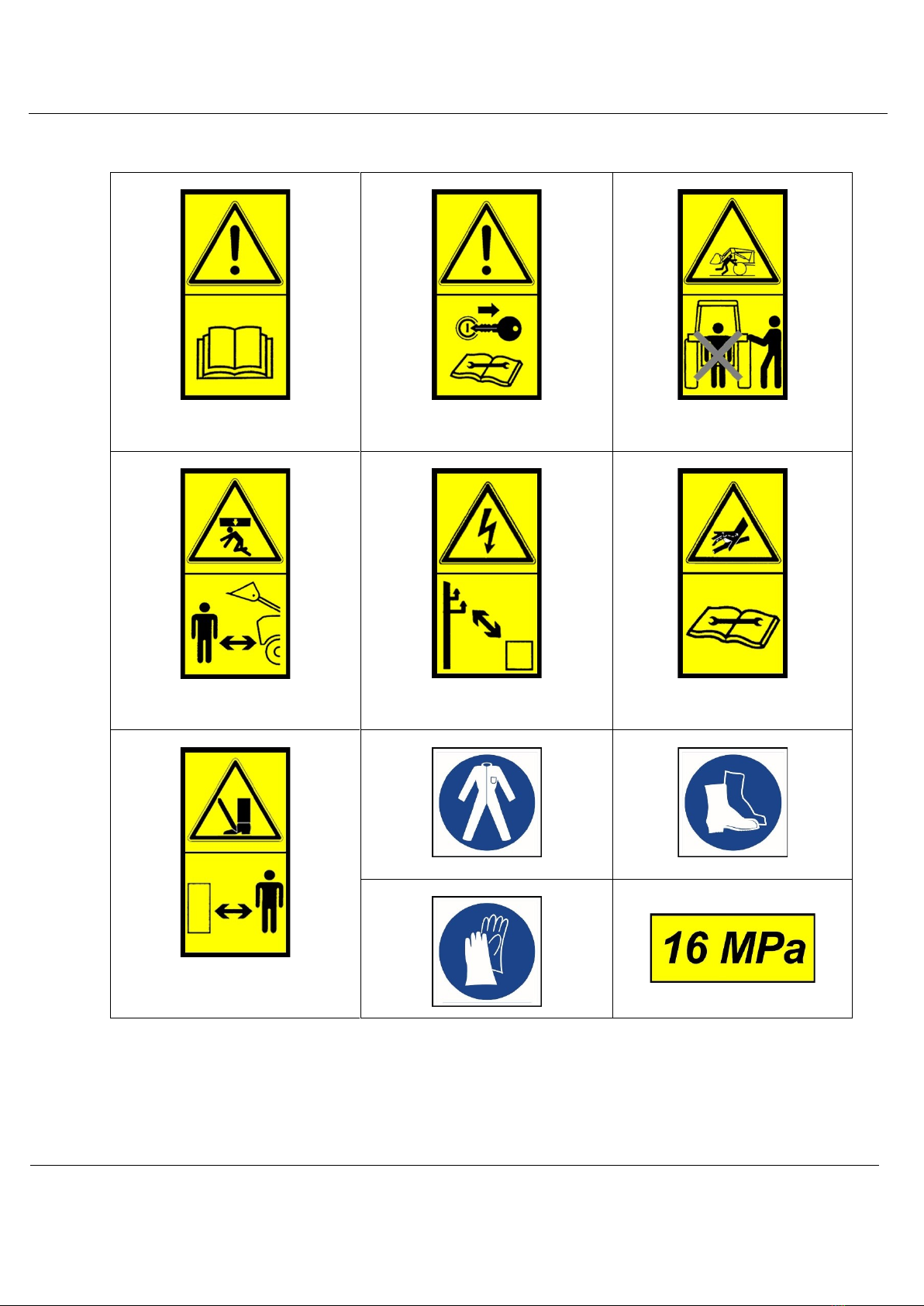

•When working on company's area you should use outline electric lighting of the vehicle

and warning signalling device (yellow), and check their working order, cleanness and

visibility. You should attach in a visible way a triangular plate distinguishing slow-moving

vehicles on a machine or in the rear of the vehicle. Reflective light and warning signs

placed on machine's construction elements should be kept clean and visible.

•In order to keep suitable control, the grapple should be adjusted to the vehicle in

accordance with the recommendations of both the vehicle and the grapple

manufacturers as well as the suspension used. Manufacturer's clamping rules are

described in chapters . 4.4 Assessing stability of a tractor with the machine attached and

5.1. Grapple assembly.

•Please remember that during work with the grapple the load of vehicle steering axle

cannot be lower than 20% and the load of driving axle cannot be lower than 45% of total

weight.

•Never leave the vehicle with the grapple attached on slopes or other terrain inclinations

without protecting it against self-rolling downwards. The grapple should be lowered on

the ground. You should place wedges under the vehicle wheels.

•Before you start any activity connected with preparation, assembly, disassembly or

adjustment you should stop the engine, switch off the drive, make the vehicle immobile

and wait until all moving parts of the machine stop and pressures cease.

•After the first hour of operation you should check the condition of all temporary

fastenings, e.g. bolted joints

•During grapple assembly and disassembly you should take special caution and be

especially careful about construction elements responsible for fastening it with the

vehicle.

•Before you start working with the grapple you should check its technical condition as well

as of a vehicle working with it. The vehicle and the grapple unit must be in good technical

condition. Worn and damaged parts should be immediately replaced with the new ones.

•The grapple must be equipped with all protective shields (if they are provided by the

manufacturer) which protect against accessing to movable parts. The protective covers

must be complete and in good working order.

•Weight of the grapple suspended on a vehicle may affect vehicle's manoeuvrability. In

such a situation great caution should be exercised.

•Keep this Instruction Manual accessible near the grapple. When you loan the grapple you

should hand it over in good working and technical condition along with the Instruction

Manual.

•Before you start working you should prepare the grapple in accordance with the

recommendations given in chapter: 5. Machine use, Grapple assembly.

•Lashing additional transport means to the grapple is strictly forbidden.