Rapid Spray FieldLink Operators Handbook

Rapid Spray Equipment by Rapid Spray REV OCT 2019

3

PRODUCT RISK ASSESSMENT

TASK HAZARDS RISK CONTROL MEASURES

1. Partially fill the

tank with water,

connect the PTO

sha - DO NOT

exceed RPM for

the PTO and test

the spray unit.

Reaching & handling;

slips, trips or falls; fingers

jammed; pressure blow;

electrocution; PTO sha

entanglement. NOTE: PTO

and machine must match;

can’t be opened when

operating or the shield is

not safely in place.

Med Concentrate on task; follow safe manual

handling techniques; don’t li > 20kg

if on your own, bend knees and keep

back straight; keep fingers clear; no

loose clothing; follow PTO & machine

safe operation steps; ensure guard on

PTO sha before use; keep unit at least

8m away from overhead powerlines;

fire extinguisher nearby; follow warning

stickers on tanks; check hoses; keep

substances away from electrical sources.

2. Check weather

and select the

appropriate PPE to

suit the chemicals

to be used.

Manual handling; slips,

trips and falls.

Low Put on PPE as per the chemical

requirements in the Material Safety Data

Sheet - coveralls, gloves, safety, footwear,

glasses and respirator; follow safe manual

handling procedures: as above.

3. Mix chemicals

and fill spray tank

units.

As above; spray dri,

chemical spillage,

emission of vapours or

flammability; weather;

untrained visitors.

Med As above; user trained in the state’s

chemical mixing and administration

course e.g. Chem Cert; follow the relevant

Environment Protection Authority

requirements, fire extinguisher present;

keep visitors away from the job unless

wearing full PPE.

4. Use spray unit.

DO NOT exceed

the RPM for the

PTO.

As above; loss of load;

work in heat and cold;

noise; exceed load limit

of vehicle; hose and PTO

sha entanglement on

terrain and slopes; run

over by unit when in use.

High As above; wear clothes to suit heat &

cold; wear hearing protection if pump

noise > 85 dBa; follow manufacturer’s

safe operation instructions for

the vehicle and the spray unit; don’t

overload-water weighs 1kg per 1 litre;

secure load to vehicle; hose tidy; brakes

on when vehicle stopped.

5. Clean up,

maintenance and

storage.

As above; PTO greasing;

fresh water tank use.

Low As above; continue to wear PPE for clean

up, store tank in a dry, well ventilated

area.

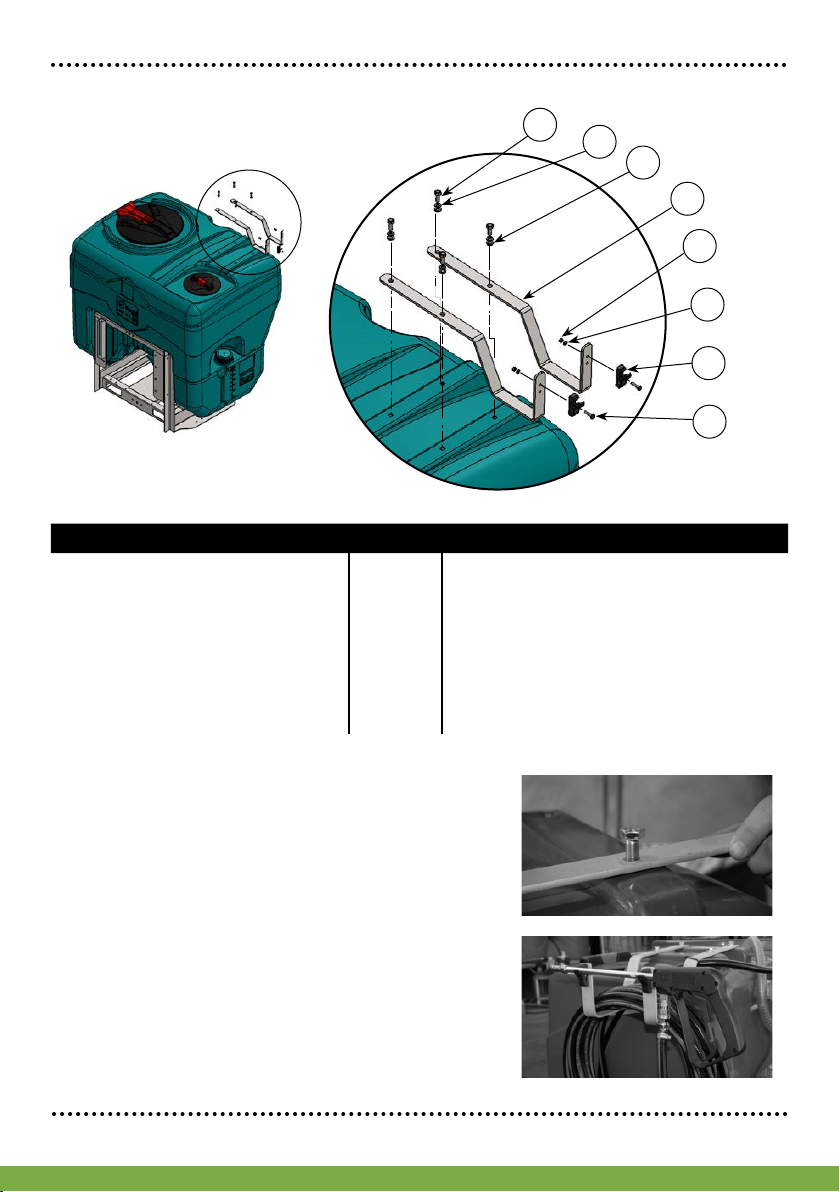

Buddy Smart Reel See ‘ Buddy Smart Reel Operators

Handbook’