English

2

SafetySafety

Important Safety

Information

Read all safety information before operating

the equipment. Save these instructions

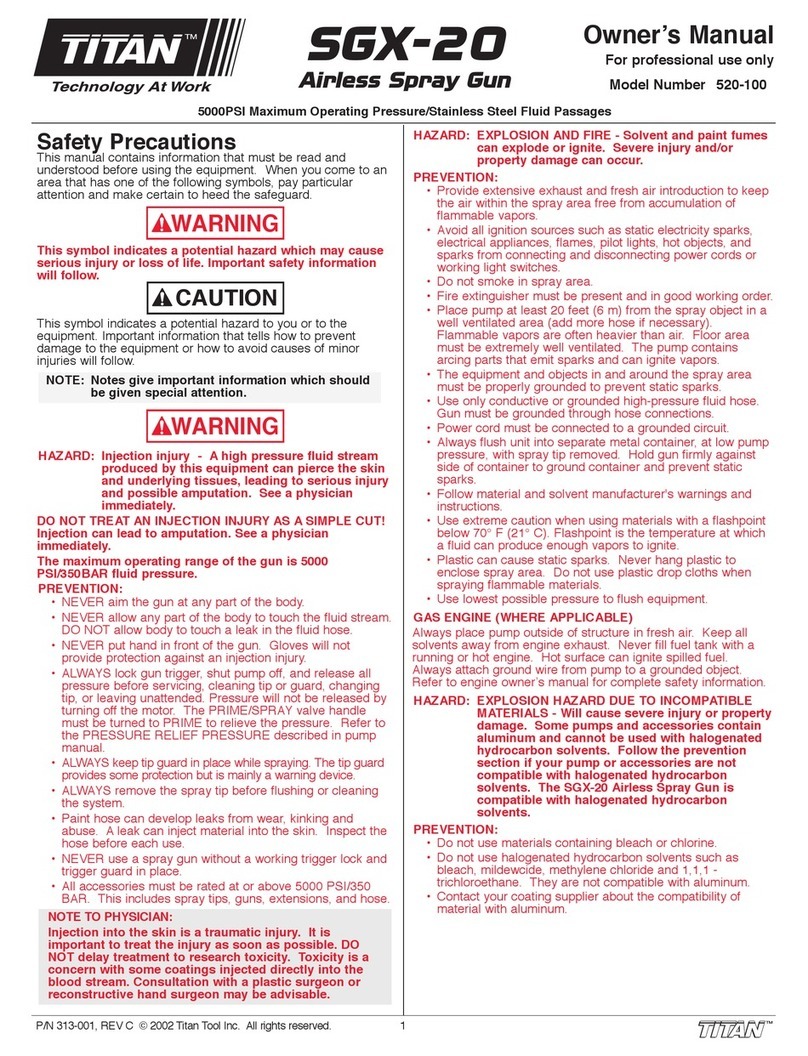

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

a) To reduce the risks of re or explosion, electrical shock

and the injury to persons, read and understand all

instructions included in this manual. Be familiar with the

controls and proper usage of the equipment.

b) WARNING - To reduce the risk of re or

explosion:

1. Do not spray ammable or combustible

materials near an open ame, pilot lights

or sources of ignition such as hot objects, cigarettes, motors,

electrical equipment and electrical appliances. Avoid creating

sparks from connecting and disconnecting power cords.

2. For units intended for use with only water-based materials

— Do not spray or clean with ammable liquids. For use with

water-based liquids only.

3. For units intended for use with only water-based or mineral

spirit-type materials with a minimum ash point of 21ºC

(69.8ºF) — Do not spray or clean with liquids having a ash

point of less than 21ºC (69.8ºF). Flash point is the temperature

at which a uid can produce enough vapor to ignite.

4. Verify that all containers and collection systems are grounded

to prevent static discharge.

5. Connect to a grounded outlet and use grounded extension

cords (electric models only). Do not use a 3 to 2 adapter.

6. Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier about

compatibility of material with aluminum.

7. Keep spray area well ventilated. Keep a good supply of fresh

air moving through the area to keep the air within the spray

area free from accumulation of ammable vapors. Keep pump

assembly in well ventilated area.

8. Do not smoke in the spray area.

9. Do not operate light switches, engines, or similar spark

producing products in the spray area.

10. Keep area clean and free of paint or solvent containers, rags,

and other ammable materials.

11. Know the contents of the paint and solvents being

sprayed. Read all Material Safety Data Sheets (MSDS)

and container labels provided with the paints and

solvents. Follow the paint and solvent manufacturer’s

safety instructions.

12. Fire extinguisher equipment shall be present and working.

c) WARNING - To reduce the risk of skin

injection:

1. Do not aim the gun at, or spray any person or

animal.

2. Keep hands and other body parts away from the

discharge. For example, do not try to stop leaks with any

part of the body.

3. Always use the nozzle tip guard. Do not spray without the

nozzle tip guard in place.

4. Only use a nozzle tip specied by the manufacturer.

5. Use caution when cleaning and changing nozzle tips.

6. High-pressure spray is able to inject toxins into the body

and cause serious bodily injury. In the event that injection

occurs, seek medical attention immediately.

7. This system is capable of producing 2800 PSI / 193

Bar. Only use replacement parts or accessories that

are specied by the manufacturer and that are rated a

minimum of 2800 PSI. This includes spray tips, nozzle

guards and extensions.

8. Verify that all connections are secure before operating the

unit.

d) WARNING - To reduce the risk of injury:

1. Always wear appropriate gloves, eye protection, clothing

and a respirator or mask when painting. Hazardous

vapors – Paints, solvents, insecticides, and other

materials can be harmful if inhaled or come in contact

with body. Vapors can cause severe nausea, fainting or

poisoning.

2. Do not operate or spray near children. Keep children

away from equipment at all times.

3. Do not overreach or stand on an unstable support. Keep

effective footing and balance at all times.

4. Stay alert and watch what you are doing.

5. Do not operate the unit when fatigued or under the

inuence of drugs or alcohol.

e) WARNING - To reduce the risk of electric

shock:

1. Keep electrical cord plug and spray gun

trigger free from paint and other liquids.

Never hold cord at plug connections to support cord.

Failure to observe may result in an electrical shock.

2. Never immerse electrical parts in water or any other

liquid. Wipe the exterior of the sprayer with a damp cloth

for cleaning.

Important safety instructions about your charger

and battery

• Before using charger, read all instructions and cautionary

markings on (1) charger, (2) battery pack, and (3) product

using battery pack.

• DANGER: 120 volts present at charging terminals. Do

not probe with conductive objects. Danger of electric

shock or electrocution.

• DANGER: If battery pack case is cracked or damaged,

do not insert into charger. Danger of electric shock or

electrocution.

• The charger and battery pack are specically designed

to work together. DO NOT attempt to charge the battery

pack with any chargers other than the ones in this

manual.

• Do not recharge battery in damp or wet environment.

• Do not expose the charger to rain or snow.

• Charge battery pack in temperatures above 40ºF (4ºC)

and below 105ºF (41ºC). Store tool and battery pack

in locations where temperatures will not exceed 120ºF

(49ºC). This is important to prevent serious damage to

the battery cells.

• These chargers are not intended for any uses other than

charging Titan rechargeable batteries. Any other uses

may result in risk of re, electric shock, or electrocution.

• To reduce risk of damage to electric plug and cord, pull by

plug rather than cord when disconnecting charger.

• Make sure cord is located so that it will not be stepped on,

tripped over, or otherwise subjected to damage or stress.

• An extension cord should not be used unless absolutely

necessary. Use of improper extension cord could result in

risk of re, electric shock, or electrocution.

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the

gauge number of the wire the greater the capacity of the

cable, that is 16 gauge has more capacity than 18 gauge.

When using more than one extension to make up the total

length, be sure each individual extension contains at least

the minimum wire size.

Recommended Minimum AWG Size for Extension Cords

Total extension cord length (feet)

25 50 75 100 125 150 175

Wire gauge

18 18 16 16 14 14 12

• The charger is ventilated through slots in the housing.

Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation

slots and result in excessive internal heat. Place the

charger on a at, non-ammable surface in a position

away from any heat source. If smoke or melting of the

case are observed, unplug the charger immediately and

do not use battery pack or charger.

• Do not operate charger with damaged cord or plug - have

them replaced immediately.