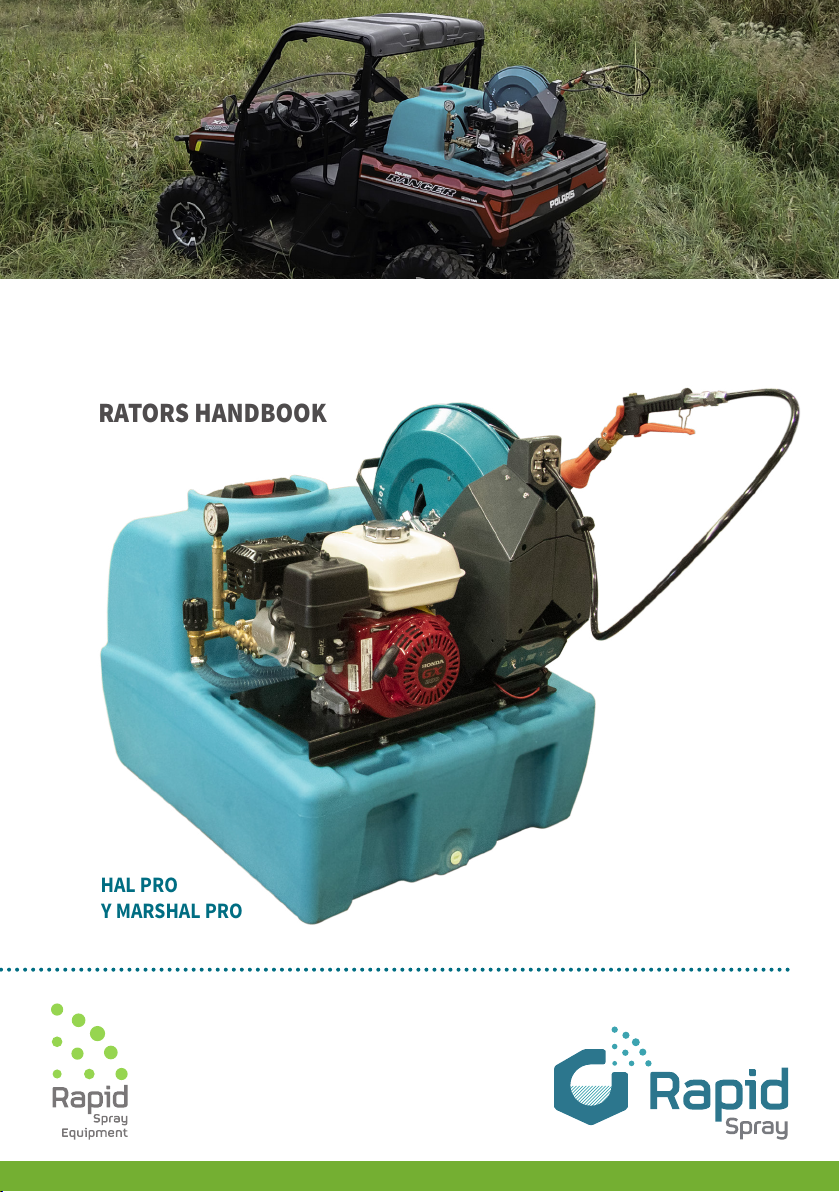

Compact Field Sprayers by Rapid Spray

Rapid Spray Marshal Pro Operators Handbook2

WARNINGS

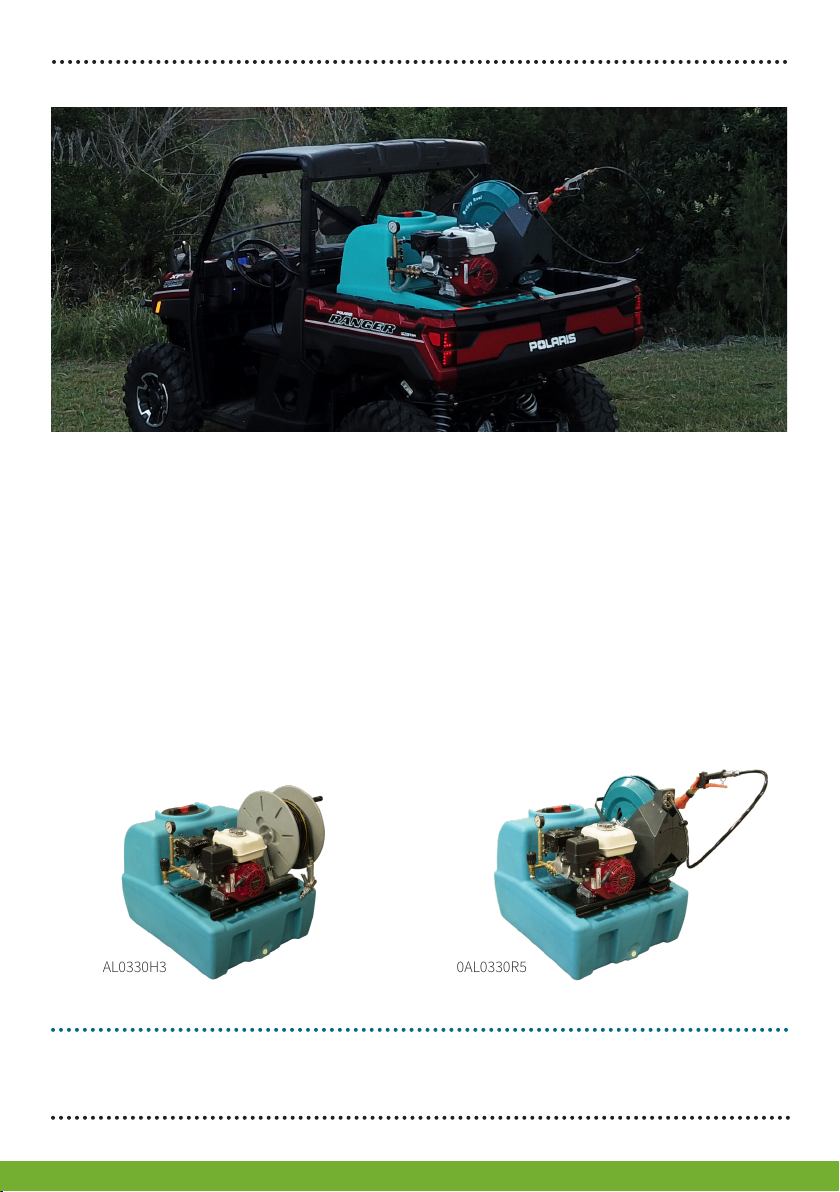

1. When mounting to any vehicle, ensure that you have read the Vehicle Owner’s Manual and

that you comply with all the weight restrictions as specified by the vehicle manufacturer,

as overloading can cause injury or death. Remember that one litre of water weighs one

kilogram. Ensure equipment is secure during transport.

2. To ensure your own safety and that of your employees or colleagues (if applicable) you

must comply with all relevant environmental, work place health and safety legislation and

codes of practice.

3. You must be in good mental health to operate this sprayer and not be under the influence of

alcohol or any drugs that could impair your vision, physical strength, dexterity, judgment or

other mental capacity.

4. Improper or careless use of this sprayer can cause serious injury. Minors should never be

allowed to use this sprayer. This sprayer should not be used when bystanders or animals

are in the area. This sprayer should never be used while children are in the area.

5. Before spraying, check the electrical and fuel systems for damage and deterioration.

Replace parts as necessary. Do not modify the equipment or use any attachments other

than those specified by the manufacturer.

6. Select and wear appropriate Personal Protective Equipment (PPE) in accordance with the

label of the product you intend on using and your own safe work practices. PPE must still

be worn while decontaminating your sprayer. Any accidental spills on the skin must be

immediately be washed with clean water and soap.

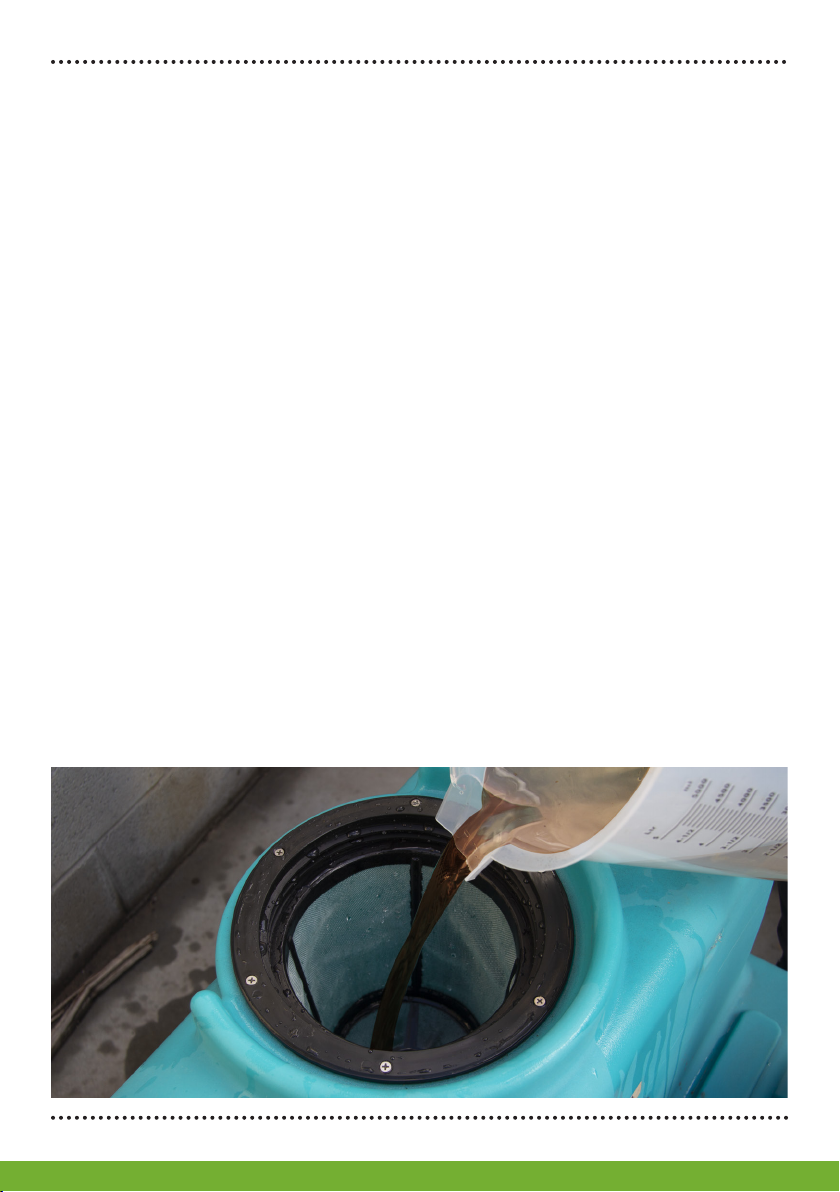

7. Turn o the engine before filling the chemical tank. Spray during the morning or evening

when it is cool. Intense sunlight will condense chemicals and may cause damage. Care

should be taken when spraying in windy conditions as spray dri may contaminate the air

and may aect the operator or damage adjacent non-target vegetation.

8. Spray only in well ventilated areas to keep away from flames or cigarettes. Keep all hoses

and equipment away from the hot engine to avoid fire hazards.

9. Do not eat, drink or smoke while spraying to avoid ingestion of chemicals. Do not carry or

store lunch boxes or other food and drink with spraying equipment.

10. Once the spraying operation has been completed, decontaminate the spray tank and spray

accessories. Store any remaining chemicals in a safe place in a sealed container. Dispose

of tank rinsing in compliance with the current environmental, work place health and safety

regulations.

11. Never leave the sprayer unattended without turning o the engine and relieving the line

pressure, and flushing the sprayer of any harmful chemicals.

12. Carry out maintenance as per the recommendations. Ensure that the unit is cool and

securely stabilised on a level surface before commencing maintenance.

Read all warnings below and obey any instruction stickers or warnings on the spray unit.

Failure to do so may result in serious bodily harm or death.