Rapid Spray Spot Ranger Operators Handbook

Rapid Spray Equipment by Rapid Spray REVA 11/05/2018

3

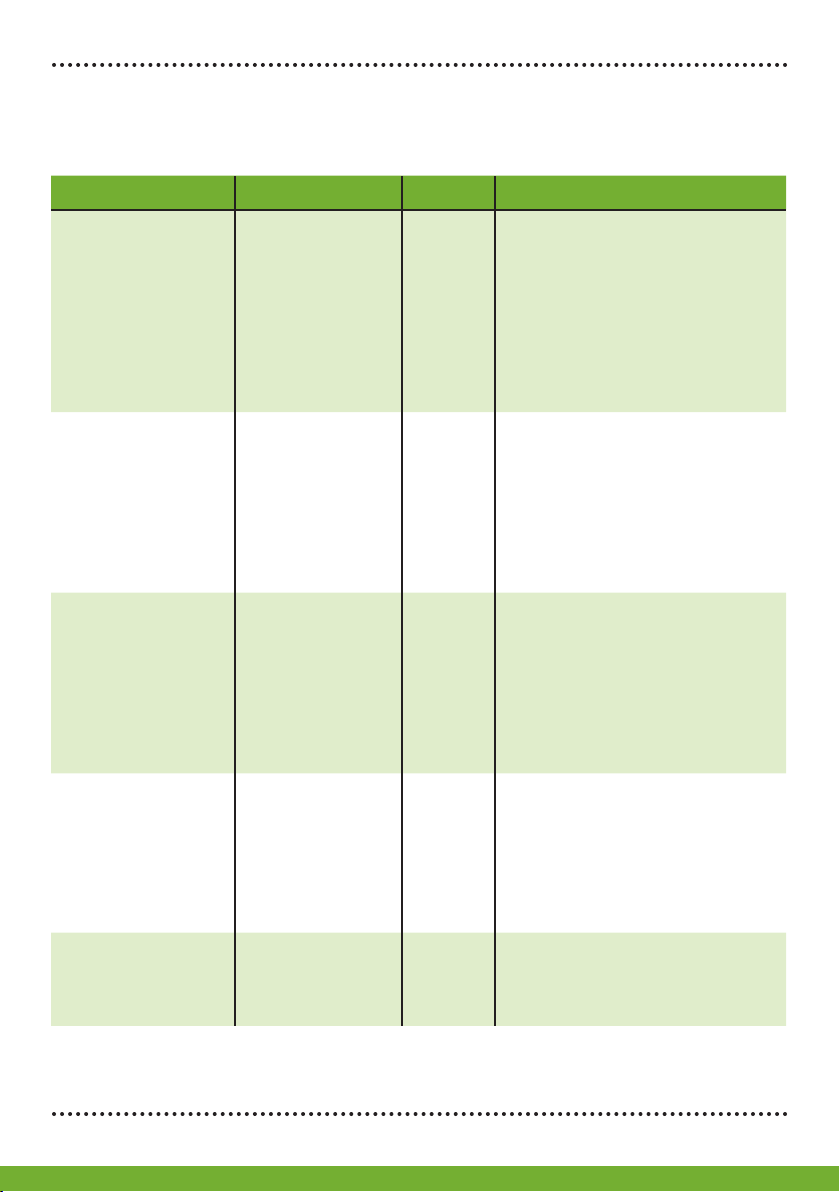

PRODUCT RISK ASSESSMENT

TASK HAZARDS RISK CONTROL MEASURES

1. Partially fill the

tank with water,

connect the battery (if

applicable) and test

the spray unit.

Manual handling;

slips, trips or falls;

finger jammed;

electric shock or

electrocution.

Medium Concentrate on tasks; follow safe

manual handling techniques: - don’t

li on your own if > 20kg, bend knees

& keep back straight; keep fingers

clear; keep unit at least 8m way

from overhead power lines; ensure

AS 3760:2001 Testing Electrical

Equipment applies; water away from

electrical sources.

2. Check weather and

weather and select the

appropriate PPE to suit

the chemicals to be

used.

Manual handling;

slips, trips and falls.

Low Put on PPE as per the chemical

requirements in the Material Safety

Data Sheet - coveralls, gloves, safety,

footwear, glasses and respirator;

follow safe manual handling

procedures: don’t li on your own if

> 20kg, bend knees and keep back

straight.

3. Mix chemicals and

fill spray tank units.

As above; spray dri,

chemical spillage,

emission of vapours

or flammability;

weather; untrained

visitors.

Medium As above; user trained in the state’s

chemical mixing & administration

course e.g. Chem Cert; follow the

relevant Environment Protection

Authority requirements, fire

extinguisher present; keep visitors

away from the job unless wearing

full PPE.

4. Use spray unit. As above; loss of

load; work in heat

and cold; noise;

exceed load limit

of vehicle; hose

entanglement;

terrain and slopes

High As above; wear clothes to suit heat &

cold; wear hearing protection if pump

noise > 85 dBa; follow manufacturer’s

safe operation instructions for

the vehicle & the spray unit; don’t

overload-water weighs 1kg per 1 litre;

secure load to vehicle; hose tidy.

5. Clean up,

maintenance and

storage.

As above. Low As above; continue to wear PPE for

clean up, store tank in a dry, well

ventilated area.

5. Once the spraying operation has been

completed, decontaminate the spray tank

and spray accessories. Dispose of rinsing’s

in compliance with current environmental,

work place health and safety regulations.

6. Personal Protection Equipment must

still be worn while decontaminating your

hose reel as per warning at 3 above.