NINOX 640 SU/USER MANUAL/01-21/REV1.0

CONTENTS

1. INTRODUCTION .............................................................................................................. 4

1.1 Scope ......................................................................................................................... 4

2. CAMERA CARE ............................................................................................................... 5

2.1 Cleaning the Sensor Window ................................................................................... 5

3. SPECIFICATION .............................................................................................................. 6

3.1 Camera Overview ...................................................................................................... 6

3.2 Datasheet ................................................................................................................... 6

4. DESIGN OVERVIEW ........................................................................................................ 7

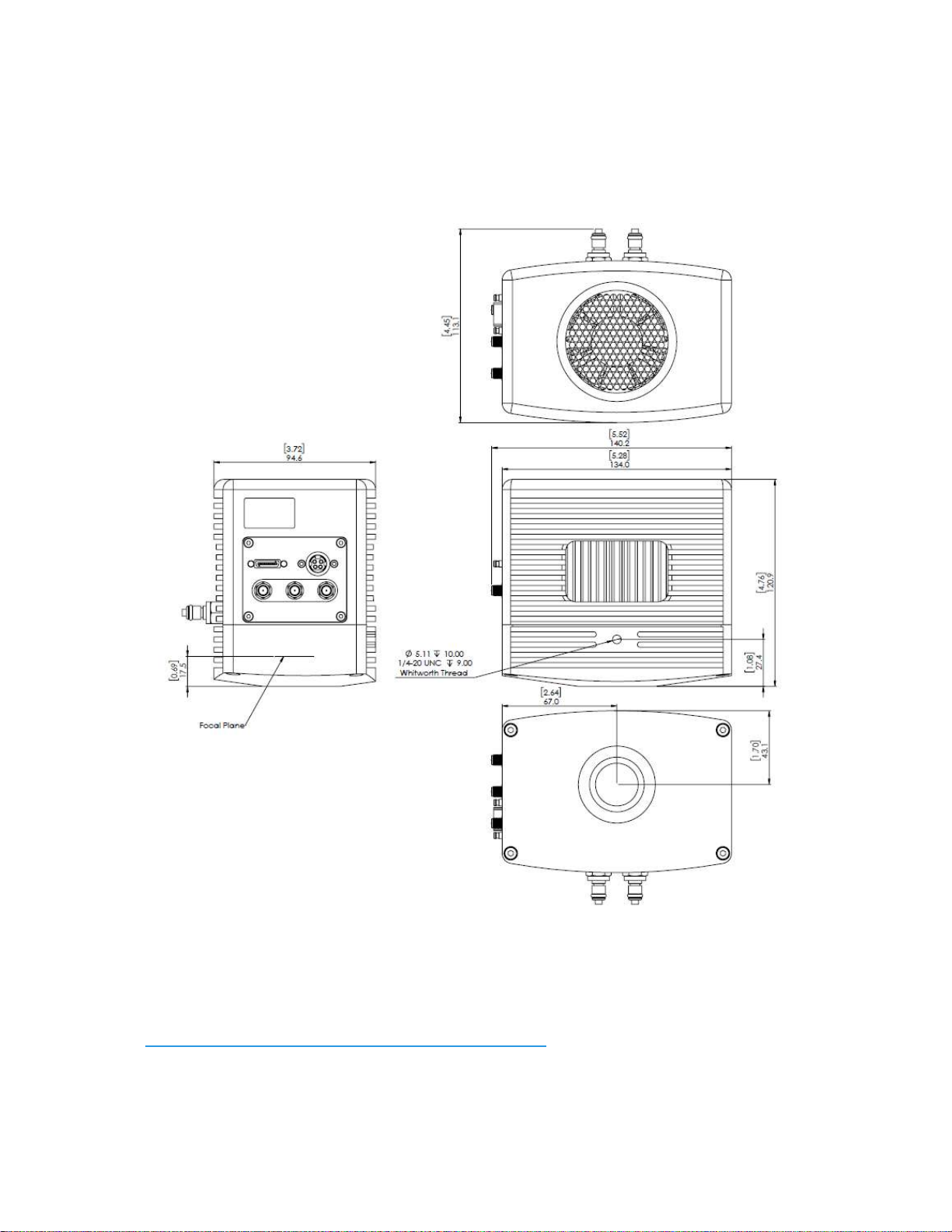

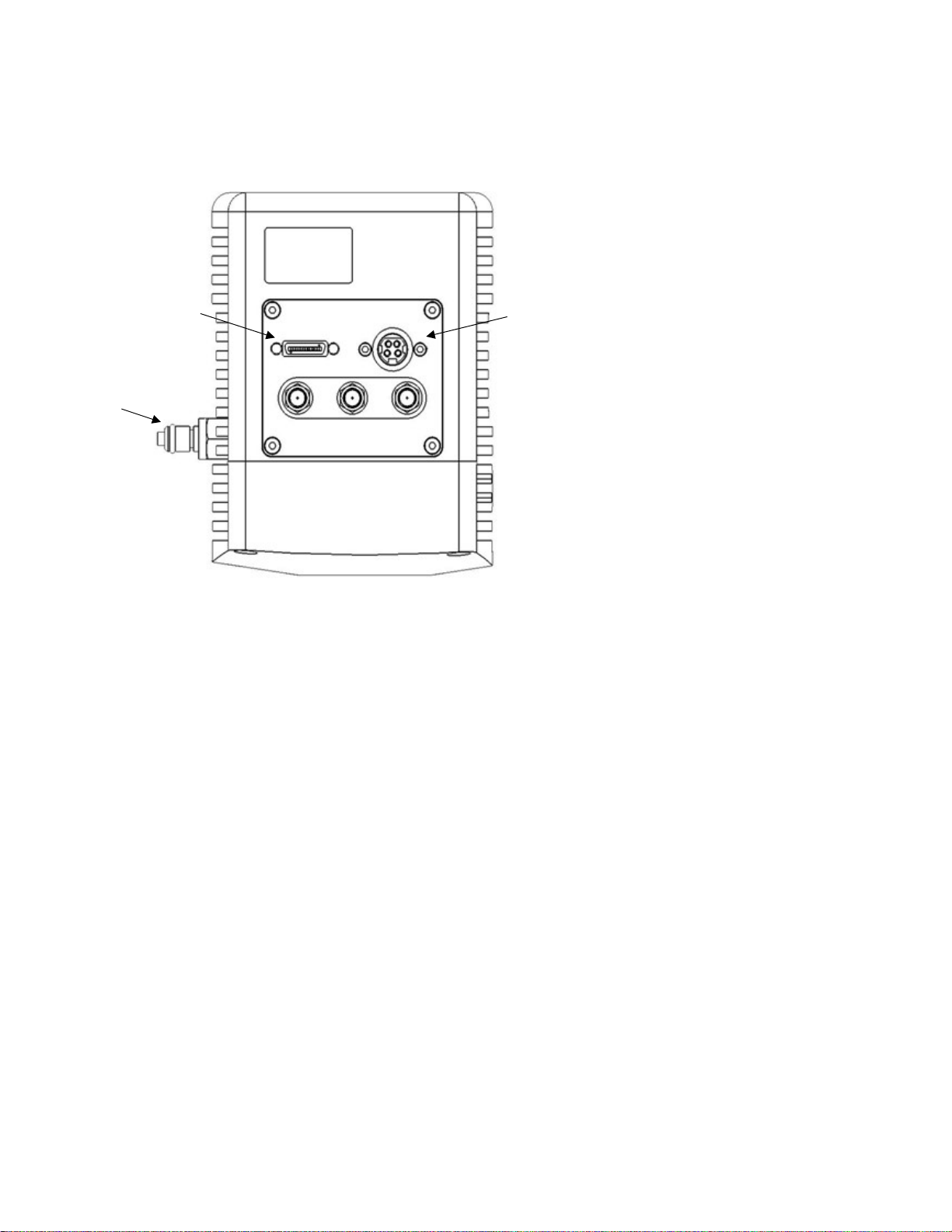

4.1 Mechanical Model ...................................................................................................... 7

4.2 Physical Interface ...................................................................................................... 8

4.3 Power Consumption .................................................................................................. 8

4.4 Mounting to a Microscope ........................................................................................ 8

4.5 Mounting to a Tripod or Optical Table ..................................................................... 8

5. SOFTWARE COMPATIBILITY ......................................................................................... 9

5.1 XCAP Compatibility ................................................................................................... 9

5.2 LabView Compatibility .............................................................................................. 9

5.3 Custom Software Interfacing .................................................................................... 9

6. CAMERA AND CHILLER SETUP .................................................................................. 10

6.1 Connecting the Camera to the Frame Grabber ...................................................... 10

6.2 Connecting Camera to Chiller ................................................................................ 10

6.3 Recommended Coolants for Chiller ....................................................................... 10

6.4 Setting the Coolant Temperature for Re-circulation ............................................. 10

6.5 Draining the Chiller, Camera and Tubing ............................................................... 11

7. FRAME GRABBER AND SYSTEM REQUIREMENTS ................................................... 12

7.1 Computer/Laptop System Requirements ............................................................... 12

7.2 Frame Grabber Requirements ................................................................................ 12

8. XCAP IMAGING SOFTWARE ........................................................................................ 13

8.1 Downloading XCAP ................................................................................................. 13

8.2 Opening the Camera Configuration ....................................................................... 13

8.3 Acquiring a Live Image Sequence .......................................................................... 15

9. CONTROLLING THE CAMERA (XCAP) ........................................................................ 16

9.1 Exposure Time and Frame Rate ............................................................................. 16

9.2 Gain Mode ................................................................................................................ 17

9.3 Trigger Mode ............................................................................................................ 18

9.4 Thermoelectric Cooler (TEC) .................................................................................. 19