TABLE OF CONTENTS

1SCOPE ............................................................................................................... 5

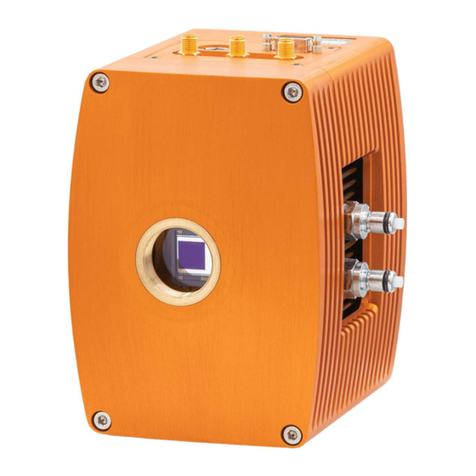

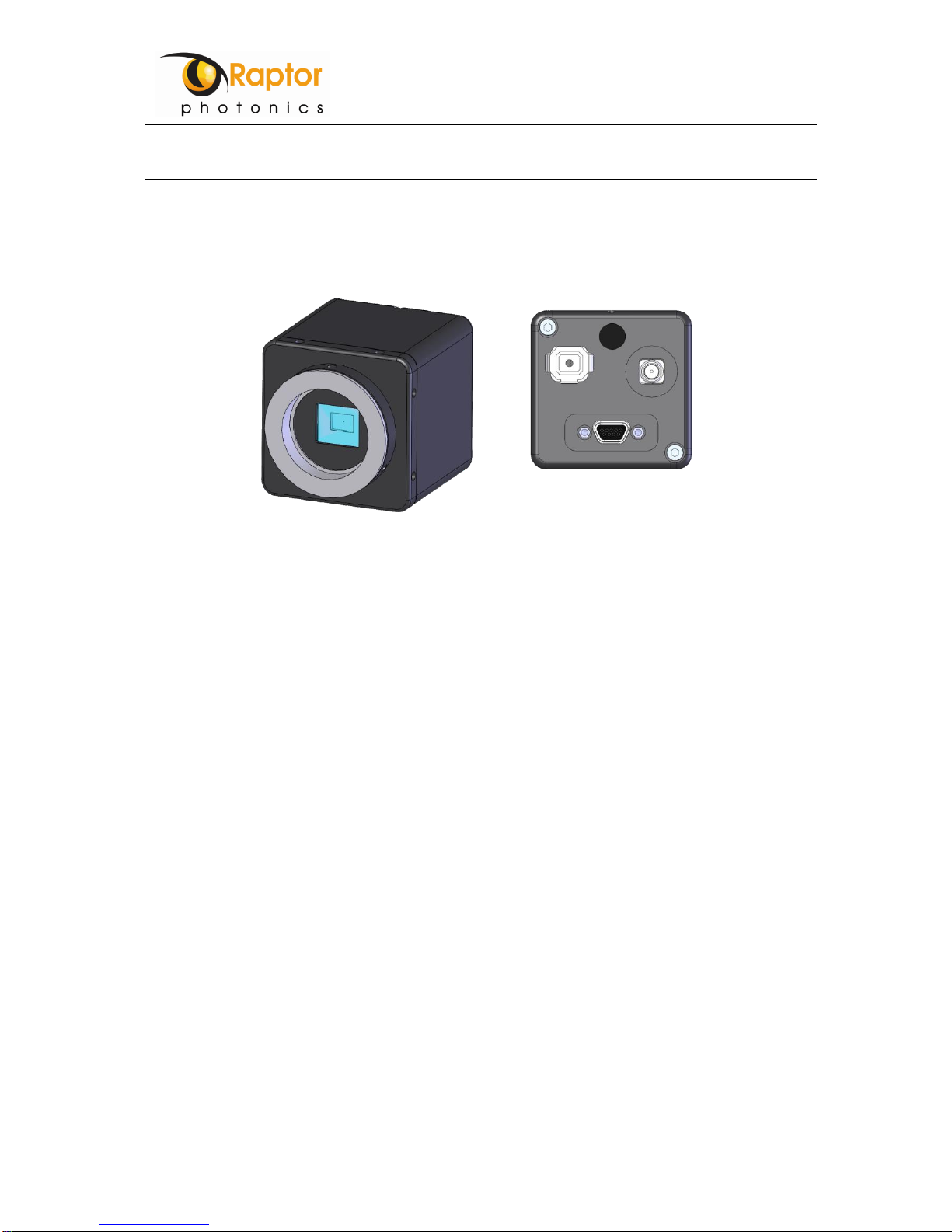

2DESIGN OVERVIEW.......................................................................................... 6

2.1 Physical Interfaces.................................................................................................................................... 6

2.1.1 Power, Trigger & Communications - 9 pin Micro-D socket (Glenair MDM-9SBSP)......................... 6

2.1.2 Video Output - SMA ........................................................................................................................ 6

2.1.3 Iris Control - 4 pin socket................................................................................................................. 6

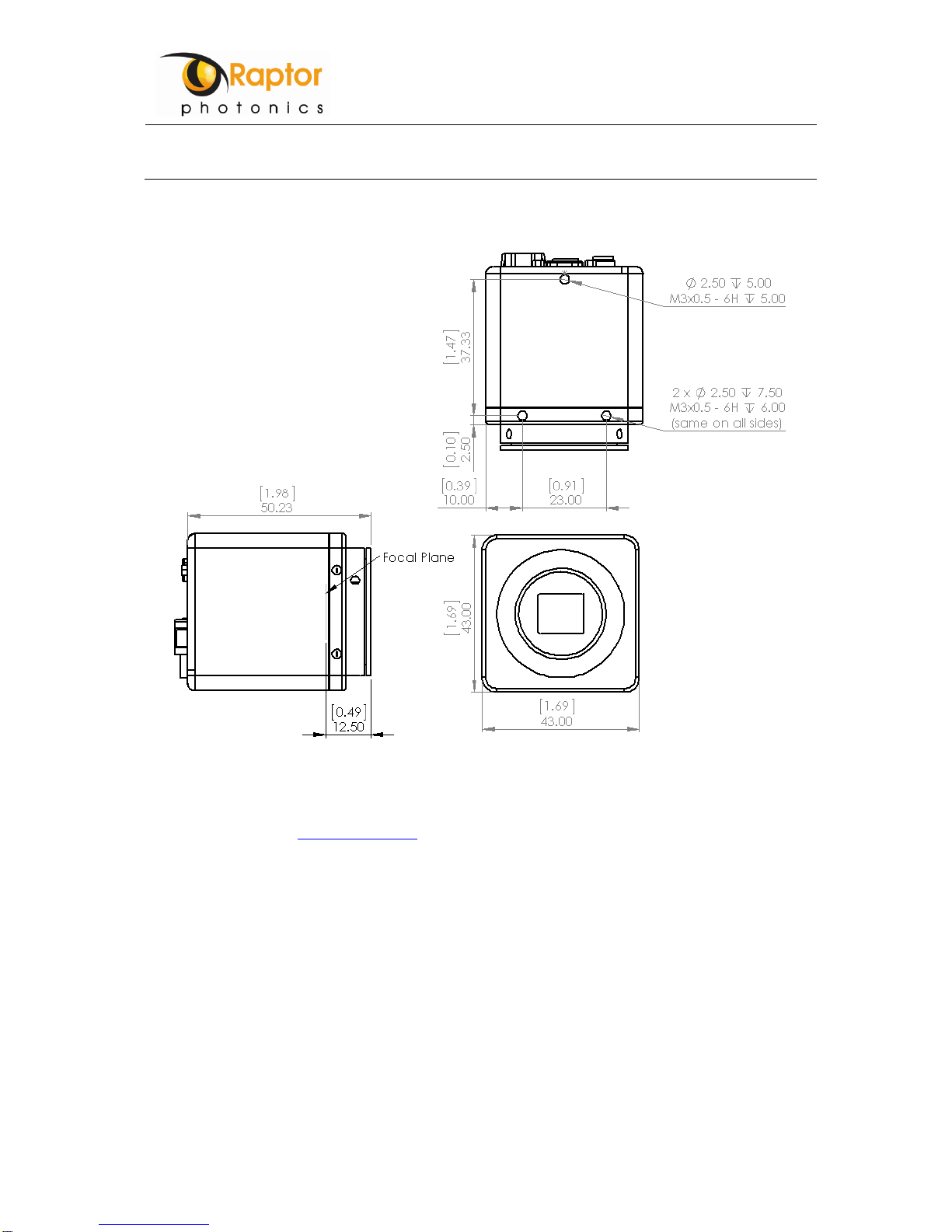

2.2 Mechanical Profile .................................................................................................................................... 7

3DESIGN DETAILS.............................................................................................. 8

3.1 Electrical Design....................................................................................................................................... 8

3.1.1 Power Input..................................................................................................................................... 8

3.1.2 Communications Interface............................................................................................................... 8

3.1.3 Trigger Output................................................................................................................................. 8

3.1.4 Analogue Video out......................................................................................................................... 8

3.1.5 Iris Control....................................................................................................................................... 9

3.2 Functionality.............................................................................................................................................. 9

3.2.1 Automatic Light Control (ALC)......................................................................................................... 9

4SERIAL COMMUNICATION (RS485) ...............................................................10

4.1 Overview..................................................................................................................................................10

4.2 ETX/Error Codes .....................................................................................................................................11

4.3 Set Commands........................................................................................................................................12

4.4 Query Commands....................................................................................................................................13

4.5 Examples.................................................................................................................................................14

4.5.1 Get System Status .........................................................................................................................14

4.5.2 Get Micro version...........................................................................................................................14

4.5.3 Read internal temperature..............................................................................................................14

4.5.4 Command acknowledge.................................................................................................................14

Figure 1: Mechanical profile drawing –SolidWorks model..................................................................................... 5

Figure 2: 9 Pin MDM connector............................................................................................................................... 6

Figure 3: Mechanical external dimensions.............................................................................................................. 7

Figure 4: Trigger Output HK829-AC........................................................................................................................ 8