CONTENTS

1. INTRODUCTION ·············································································································· 1

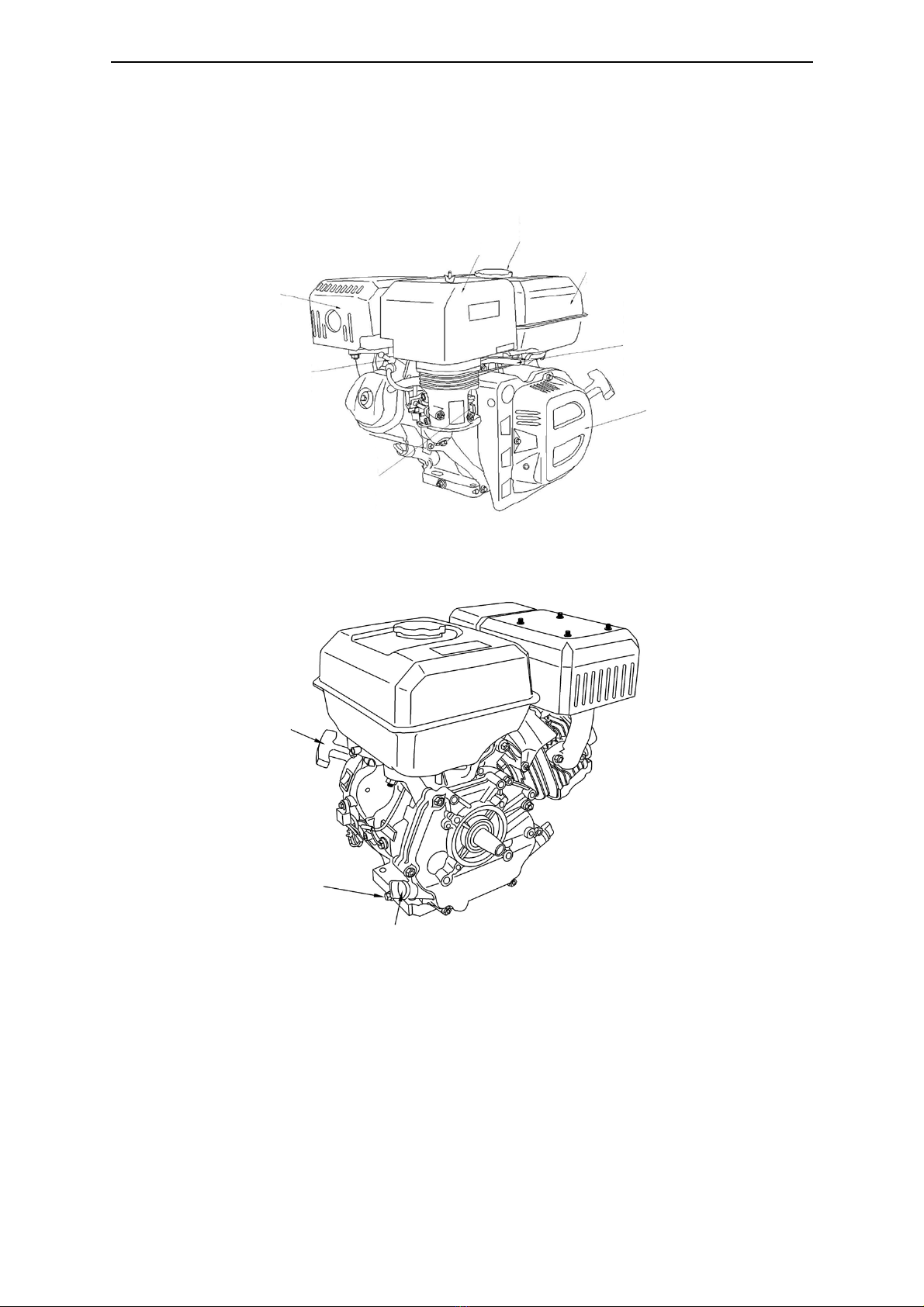

1-1 PARTS DESCRIPTION····························································································· 1

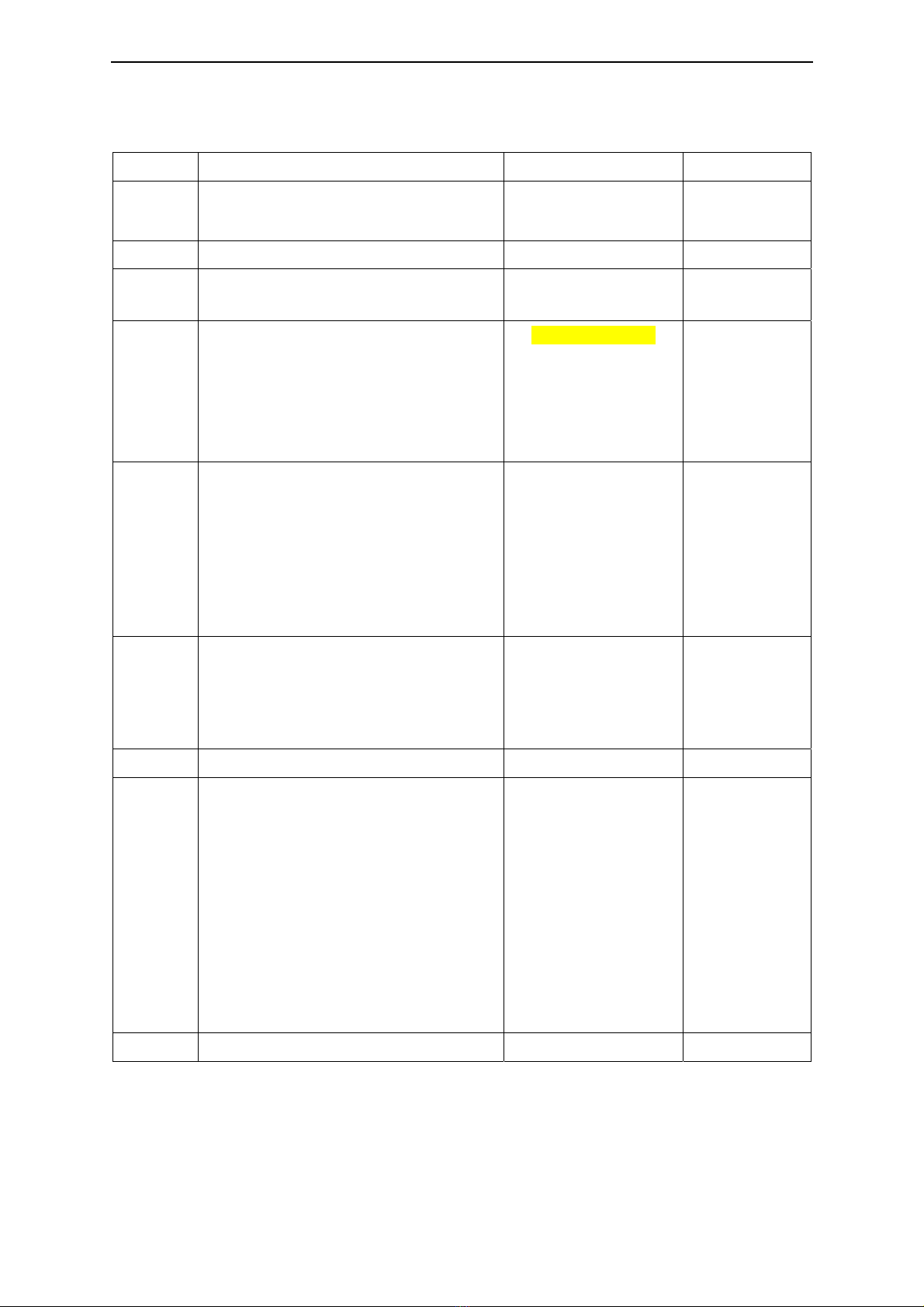

1-2 SPECIFICATION ······································································································ 2

1-3 SERVICE LIMIT······································································································· 3

2. DIMENSIONS AND TORQUE·························································································· 6

2-1 ENGINE DIMENSIONS··························································································· 6

2-1-1 R100······················································································································· 6

2-1-2 R80/R160/R180/R200/R210/R225 ·································································· 7

2-1-3 R270/R280/R300····························································································· 8

2-1-4 R390/R420/R440····························································································· 9

2-2 TORQUE VALUES ································································································· 10

2-3 STANDARD Torque valueS ···················································································· 12

3. MAINTENANCE ············································································································· 13

3-1. Maintenance schedule····························································································· 13

3-2 engine oil ················································································································· 14

3-3 Air cleaner ··············································································································· 15

3-4 Cleaning of the fuel filter························································································· 15

3-5 spark plug cleaning and adjusting ············································································ 16

3-6 valve clearance adjustment ······················································································ 16

3-7 governor··················································································································· 17

4. DISASSEMBLING AND SERVICING ··········································································· 18

4-1 Troubleshooting······································································································· 18

4-1-1 Hard starting·································································································· 18

4-1-2 Engine lacks power························································································ 20

4-1-3 Speed is unstable ··························································································· 21

4-1-4 Motor is unable to start·················································································· 21

4-1-5 Exhaust gas color is abnormal ······································································· 22

4-1-6 Unable to ignite ····························································································· 22

4-1-7 Oil alert system malfunction·········································································· 23