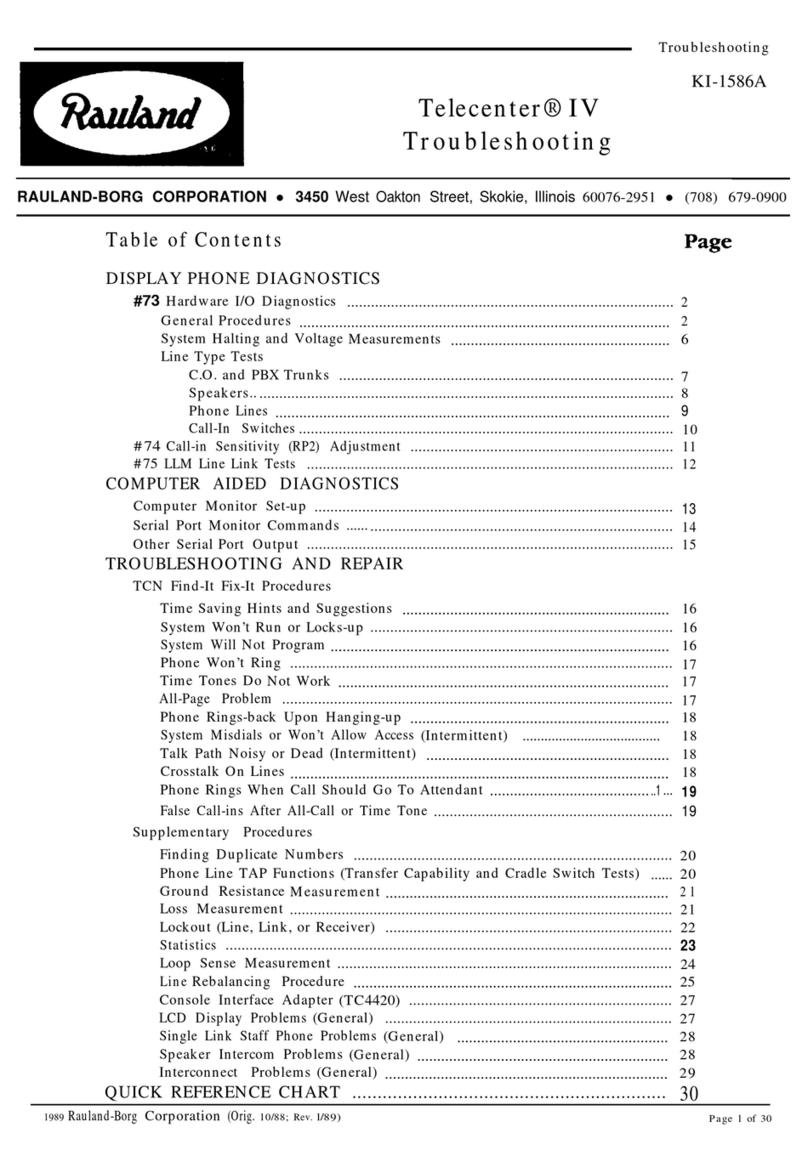

Installation

FCC Requirements

Rauland-Borg’s Model

TC4171

(COA Module) conforms to the requirements of the Federal

Communica-

tion Commission’s Rules and Regulations, Part 68, which governs the connection of circuitry to protect

the telephone network. The user must be aware of the requirements pertaining to the installation and

the operation of this protective device. The rules are summarized below; the complete current rules will

be in the current copy of the FCC’s Rules.

All

of the pertinent rules must be followed.

1.

The TC4171 (COA) should only be connected to a standard subscriber line via the proper

coupler installed by the telephone company; it should never be connected to a party line or

coin line.

2. You must give the local telephone company:

a.

notice that you want to install an FCC-approved device to their line (similar notice is

required of a final disconnect.)

b. the registration number and the ringer equivalence, which are marked on the

compliance

label,

and

C. the connection required for the TC4 171 (COA)

-

the

RJ2

1X, RJ 1

lC,

or RJ 11W (see this

manual, KI-1583, the

Interconnect

Planning Manual, KI-1582 and wiring diagrams

KM-0714 and KM-0716).

3. Once the telephone company has installed the proper connector, insert the plug coming from

the TC4 171 (COA) wire-wrap terminals.

4. No repairs may be made to the TC4171 (COA) or to the

TC4001

(main central assembly) while

the TC4171 is

connected

to the phone line. If any malfunction occurs on this interconnect

device or with the

TC4001,

disconnect the TC4171 and replace it with a unit known to be

operating. If the Telecenter equipment is adjudged to be operating properly but the problem

still exists, contact the telephone company. Reconnect the phone system only after determining

that this equipment is not the source of the malfunction.

5. If the TC4171 (CGA) should cause harm to the telephone network, the telephone company is

required, where practicable, to notify you that temporary discontinuance of service may be

required. If advance notice is not practicable, the telephone company is permitted to discon-

tinue its service immediately, provided that such an action is reasonable under the circum-

stances In the case of temporary discontinuance, the telephone company is required to:

a.

Promptly notify you of the temporary discontinuance.

b.

Give you the opportunity to

correct

the situation that caused the discontinuance

C.

Inform you of your rights to bring a complaint to the FCC pursuant to the procedures set

forth in that agency’s Rules. Copies of the procedure for making a complaint can be

obtained from Rauland-Borg.

6. The telephone company can make changes in its facility, operations, equipment, or procedures,

provided that the changes are reasonably required and are consistent with the FCC’s regulations.

If these changes render the customer’s equipment incompatible or require that it be

modifed,

the

telephone company is required to give sufficient advance notice in writing to allow the customer

the opportunity to maintain uninterrupted service.

7. Do not modify, repair, or alter this registered interconnect device, the

TC4171

(COA): any such

actions will void the warranty and could result in discontinuance of service from the telephone

company. If the TC4171 requires service, return it to the Rauland-Borg Corporation.

Page 2 of 20

©

1989 Rauland-Borg Corporation (Orig.

10/88;

Rev. 1/89)