RE317 SERIES,

Addressable Photoelectric Smoke And/or ROR & Fixed

Temperature Heat Detector

Installation Wiring Diagram

TYPICAL WIRING DIAGRAM

OPTIONAL RETURN WIRING

LOOP

COMPATIBLE

CONTROL

PANEL

RE316 2 WIRE DETECTORS WIRING DIAGRAM

EOL

RESISTOR

OPTIONAL REMOTE LED OPTIONAL REMOTE LED

5

62

45

62

4

Note: Don’t install terminal 4 and 6 for the models without remote LED

output.

THE RE317 SERIES REQUIRE COMPATIBLE ADDRESSABLE COMMUNICATIONS TO

FUNCTION PROPERLY MOREOVER.

THE INSTALLATION MUST BE IN COMPLIANCE WITH THE CONTROL

PANEL SYSTEM INSTALLATION MANUAL.

Panel Compatibility: AVANI by Ravel.

WARNING

TO PREVENT DETECTOR CONTAMINATION AND SUBSEQUENT

WARRANTY CANCELLATION, THE SMOKE DETECTOR MUST REMAIN

COVERED UNTIL THE AREA IS CLEAN AND DUST FREE.

GENERAL DESCRITPTION

RE317 series are the photo electronic smoke detectors and/or ROR & Fixed

temperature detectors combined with advanced addressable-analog

communications. The DIP switches are provided for setting the detector’s

address that is RE317D series; To models without dip-switch, the detector is

addressed by RE317A programmer. Please refer to RE317A PROGRAMMER

USE’S MANUAL

.

Model Dip-switch Smoke

sense

Heat

sense

Remote

LED

RE317D-SHL

√

√

√

√

RE317D-SL

√

√

√

RE317D-HL

√

√

√

RE317D-SH

√

√

√

RE317D-S

√

√

RE317D-H

√

√

RE317A-SHL

√

√

√

RE317A-SL

√

√

RE317A-HL

√

√

RE317A-SH

√

√

RE317A-S

√

RE317A-H

√

Note: 1

、

The base model No. for RE317D(A)-S, RE317D(A)-SH and RE317D(A)-H

is P/N RE-312.

The base model No. for RE317D(A)-SL, RE317D(A)-SHL and

RE317D(A)-HL is P/N RE-314

.

INSTALLING THE BASE

1. To insure proper installation of the detector head to the base, all the wires

should be properly addressed at installation:

(A) Position all the wires flat against terminals.

(B) Fasten the wires away from connector terminals.

2. The detectors are intended for mounting on a ceiling or a wall at open area

must be in accordance with the fire standard in your country

.

3. The base of the smoke detector can be mounted directly onto an electrical

junction box such as an octagonal (75mm, 90mm or 100mm), a round (75mm),

or a square

(100mm) box without using any type of mechanical adapter.

INSTALLING THE HEAD

1. Set the desired address via DIP switch on the back of the detector, see

ADDRESS SETTING section.

(

RE317A Series have no window on the back of

the detector

)

2. Align the components as shown in Figure 2.

3. Mate the detector head onto the base and twist clockwise to secure it.

4. After all detectors have been installed, apply power to the control unit and

activate the communication line.

5. Test the detector(s) as described in the TESTING section of this manual.

Note: Do not install the detector head until the area is thoroughly cleaned

of construction debris, dusts, etc. Please refer to control panel technical

information to decide the maximum number of detector installed in the

same loop.

Fig. 2 Mating detector head onto base.

TESTING

All the alarm signal services, releasing device and extinguisher system should

be disengaged during the test period and must be re-engaged immediately at

the conclusion of testing

.

SMOKE SENSOR TESTING

Allow smoke from a cotton wick or a test smoke aerosol to enter the detector-sensing

chamber for at least 10 seconds. When sufficient smoke has entered the chamber, the

detector will signal an alarm, this being visible by a continuous illumination of the red

LED. Make sure to drive smoke out of the chamber before reset LED in order to keep

the detector a current sensitivity. If the alarm fails in this step, it indicates a defective unit,

which require to be returned to the distributor for servicing.

HEAT SENSOR TESTING

The detector to be tested should be subject to a flow of warm air at a temperature of between

65°C and 80°C. (This requirement can be met by some domestic hair dryers).

Proceed as follows:

1. Switch on the warm airflow and check that temperature is correct and stable.

2. From a distance of several inches, direct the airflow at the guard protecting

the thermistor. The detector should alarm within 30 seconds.

3. Upon alarm immediately remove the heat source and check that the red LED

of the detector is illuminated.

4. If detector fails to go into alarm mode within 30 seconds it is too insensitive

and needs to be returned to the distributor for servicing.

NOTE: After testing, check that the system is set for normal operation and

notify the appropriate authorities that the testing operation is complete and

the system is active again.

Smoke detectors are not to be used with detector guards

unless the combination has been evaluated and found

suitable for that purpose.

MAINTENANCE

The recommended minimum requirement for detector maintenance consists of

an annual cleaning of dust from the detector head by using a vacuum cleaner

cleaning program should be agreed to the individual environment in

conformance with the fire standard in your country.

CAUTION: DO NOT ATTEMPT TO DISASSEMBLY OF THE FACTORY

SEALED SMOKE DETECTOR. THIS ASSEMBLY IS SEALED FOR YOUR

PROTECTION AND IS NOT INTENDED TO BE OPENED FOR SERVICING BY

USERS. OPENING THE DETECTOR HEAD WILL VOID THE WARRANTY.

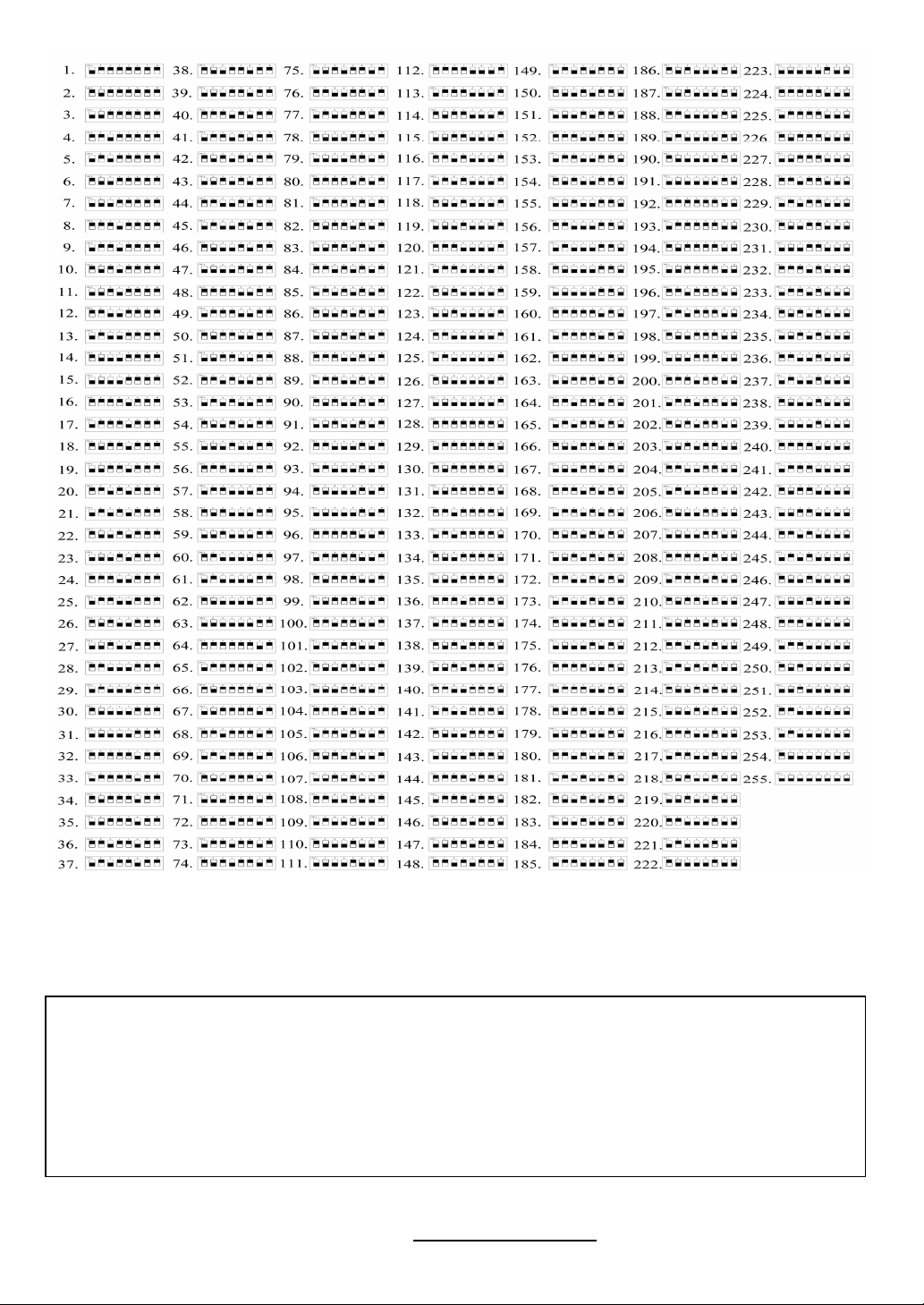

ADDRESS SETTING

.

1.Please refer to fig.3 to via DIP SWITCH to set detector address.

Fig.3: the location of dip switch

2. The definition of address is depicted as follows.

BRACKET

LED ALIGN

LED

DETECTOR HEADRECTANGULAR