1

TABLE OF CONTENTS

016-0190-037

08/04

1903 without POWER BEYOND ........................................................................................................ 2

MOUNTING THE UNIVERSAL BRACKET......................................................................................... 2

MOUNTING THE STEERING POSITION SENSOR ........................................................................... 2

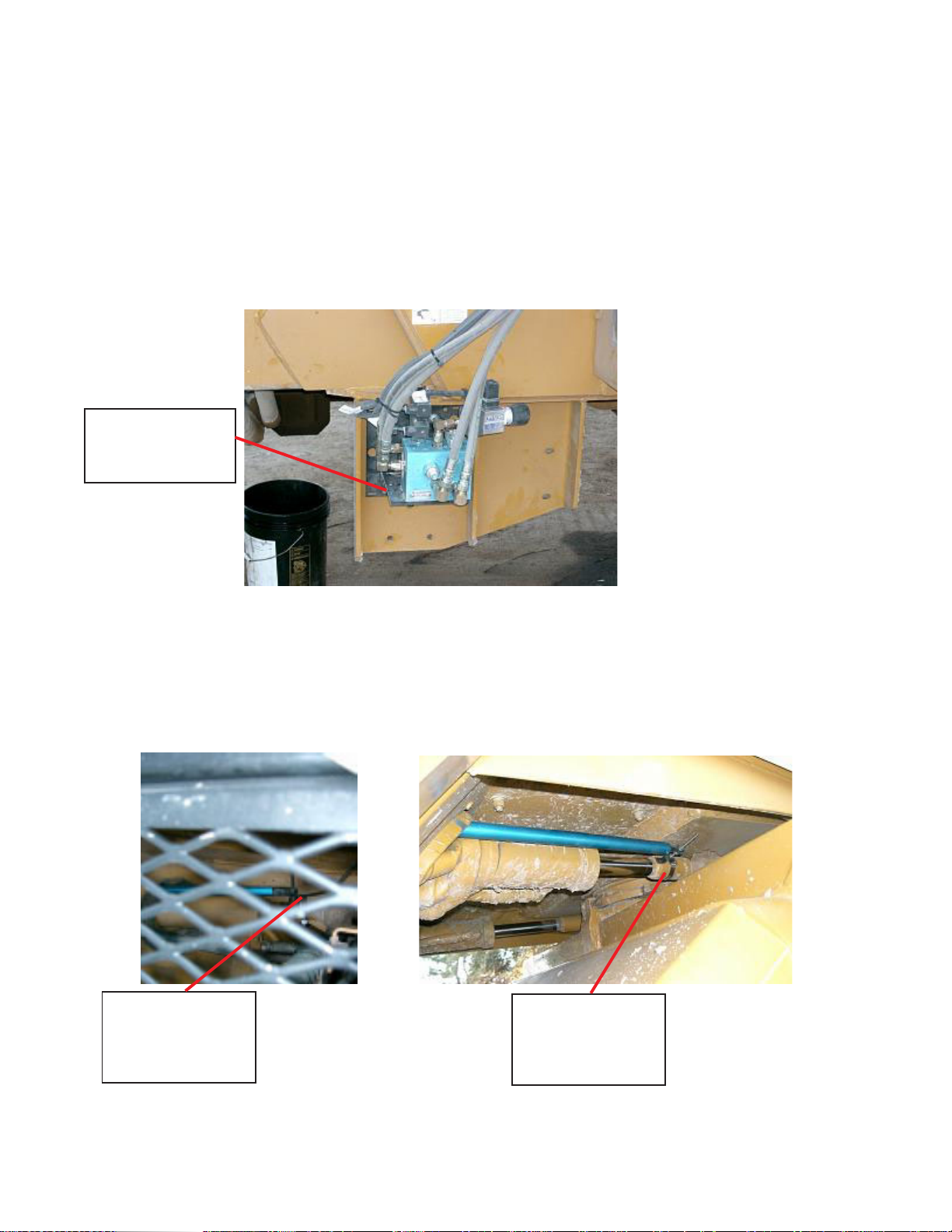

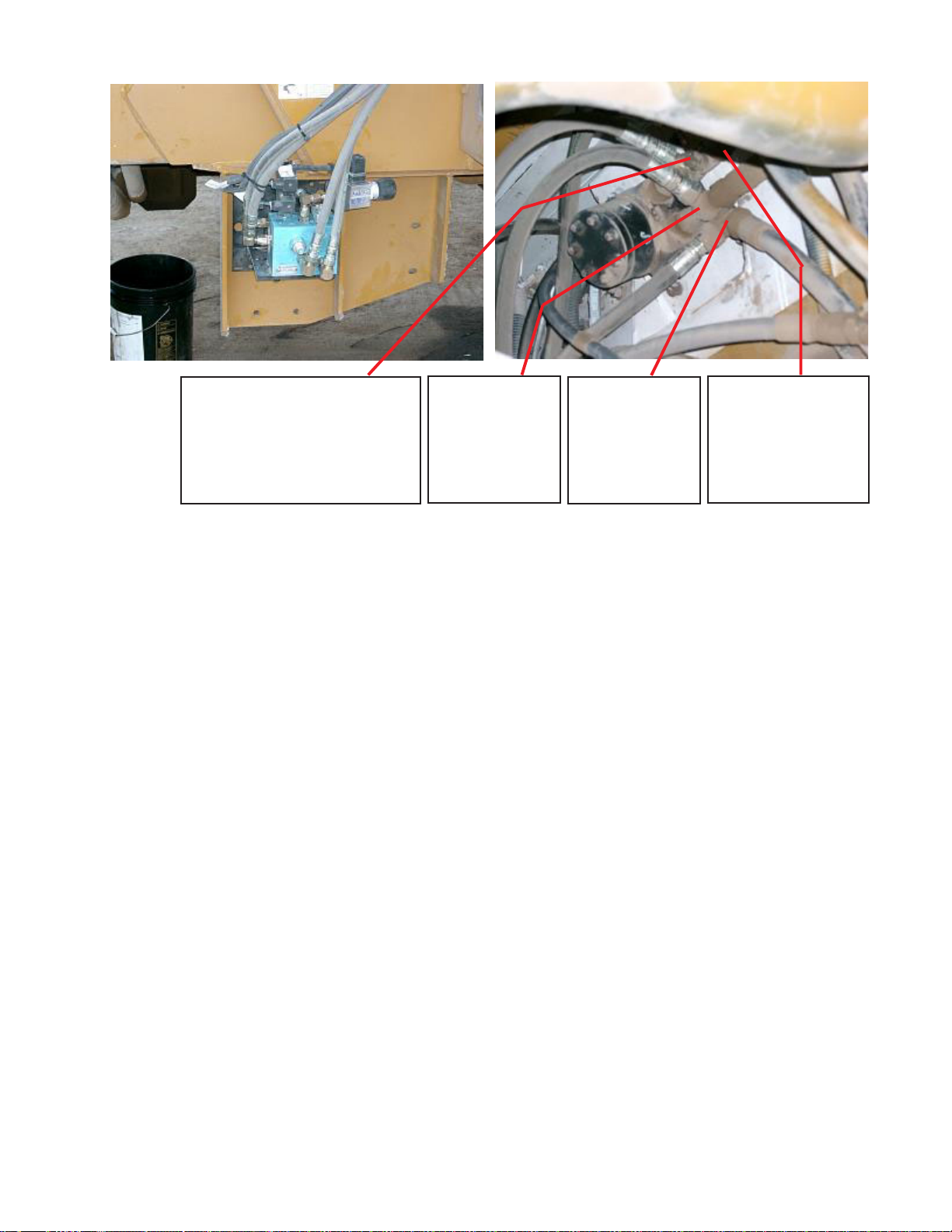

MOUNTING THE HYDRAULIC VALVE............................................................................................... 3

MOUNTING THE PRESSURE SWITCH ............................................................................................. 3

HOSE CONNECTIONS AND ROUTING ............................................................................................. 4

PRESSURE HOSE .................................................................................................................. 5

EXCESS FLOW HOSE ............................................................................................................ 5

TANK PORT HOSE..................................................................................................................5

LEFT STEER HOSE ................................................................................................................ 5

RIGHT STEER HOSE .............................................................................................................. 6

1903 with POWER BEYOND .............................................................................................................. 7

MOUNTING THE UNIVERSAL BRACKET.......................................................................................... 7

MOUNTING THE STEERING POSITION SENSOR ........................................................................... 7

MOUNTING THE HYDRAULIC VALVE............................................................................................... 8

MOUNTING THE COUNTERBALANCE VALVE, PRESSURE SWITCH & NEEDLE VALVE ........... 8

HOSE CONNECTIONS AND ROUTING ............................................................................................. 8

PRESSURE HOSE .................................................................................................................. 9

EXCESS FLOW HOSE ............................................................................................................ 9

TANK PORT HOSE..................................................................................................................9

NEEDLE VALVE HOSE ........................................................................................................... 9

CB TO LEFT STEER HOSE .................................................................................................. 10

CB TO RIGHT STEER HOSE................................................................................................ 10

B-PORT TO COUNTERBALANCE HOSE ............................................................................ 10

A-PORT TO COUNTERBALANCE HOSE ............................................................................ 10