1

TABLE OF CONTENTS

SYMBOL DEFINITION .............................................................................................................................................. 3

INTRODUCTION....................................................................................................................................................... 4

INSTALLATION ......................................................................................................................................................... 5

1. INSTALLATION OF DRIVE SHAFT SPEED SENSOR ......................... 5

2. MOUNTING THE FLOW METER ........................................... 6

3. MOUNTING THE GRANULAR ENCODER ..................................... 7

4. MOUNTING THE LIQUID AND GRANULAR CONTROL VALVES .................. 8

5. MOUNTING THE CONSOLE AND CABLING.................................. 8

CONSOLE FEATURES ............................................................................................................................................ 9

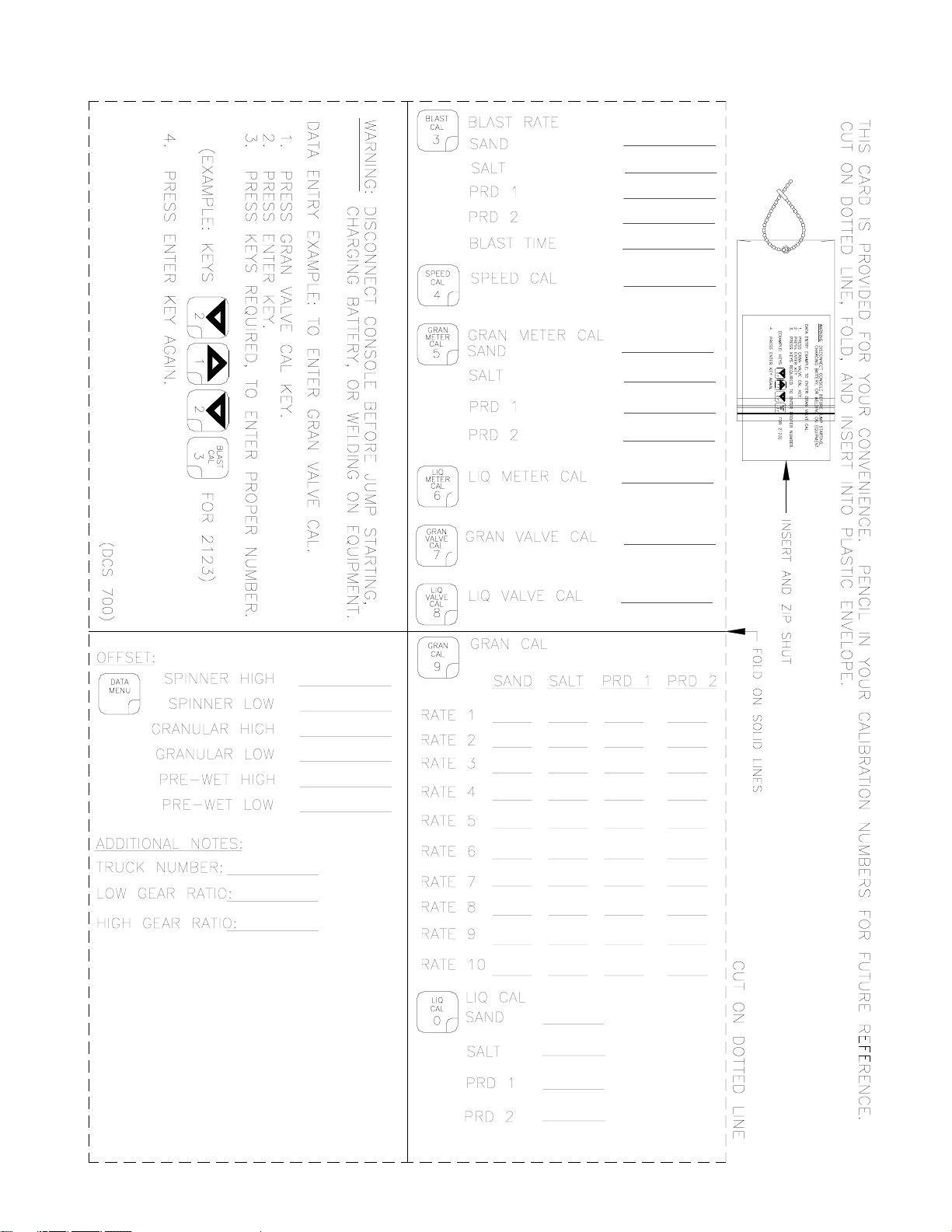

CONSOLE PROGRAMMING ................................................................................................................................. 10

1. INITIAL CONSOLE PROGRAMMING ...................................... 11

CONSOLE CALIBRATION ..................................................................................................................................... 14

1. CALCULATING OFFSETS .............................................. 14

2. CALCULATING "SPEED CAL" .......................................... 17

3. CALCULATING "GRAN METER CAL" ..................................... 18

4. VERIFYING "GRAN METER CAL" ....................................... 19

5. CALCULATING "LIQ METER CAL" ...................................... 20

6. CALCULATING "GRAN AND LIQ VALVE CAL" ............................ 20

OTHER CONSOLE FEATURES ............................................................................................................................ 20

1. SELF TEST FEATURE ................................................ 20

2. SPEED LIMIT FEATURE .............................................. 22

3. DISTANCE & VOLUME DISPLAYS ....................................... 22

4. VOLUME/GRAN AND VOLUME/LIQ ....................................... 24

5. BLAST BUTTON ..................................................... 24

6. MANUAL MODE LOCK OUT ............................................. 24

7. CONTROL VALVE DELAY .............................................. 24

8. AUTOMATIC RATE +/- ............................................... 25

9. LOW TANK ALARM ................................................... 25

10. LOW LIMIT FLOW ALARM ............................................ 25

DATA MENU ........................................................................................................................................................... 26

SERIAL PORTS SCREENS ................................................................................................................................... 26

GLOBAL POSITIONING SYSTEM SCREENS ...................................................................................................... 29

DATE SCREENS .................................................................................................................................................... 29

FLOW RATE SCREENS......................................................................................................................................... 30

ALARM SCREENS.................................................................................................................................................. 31

MISCELLANEOUS SCREENS............................................................................................................................... 33

OFFSET SCREENS................................................................................................................................................ 34

CAL SCREENS ....................................................................................................................................................... 34

SAND BLAST SCREENS ....................................................................................................................................... 35

SALT BLAST SCREENS ........................................................................................................................................ 35

PRODUCT 1 BLAST SCREENS ............................................................................................................................ 36

PRODUCT 2 BLAST SCREENS ............................................................................................................................ 36

PREWET BLAST SCREENS ................................................................................................................ 36

Continued on page 2

016-0159-775

7/99