RudderControls

Collecttheseparts.

ÿ 1 rudderServoandmountinghardware(minimum70oztorque)

ÿ 1 rudderwirecable

ÿ 4 cablecrimpfittings

ÿ 4 cableclevises

ÿ 4 cableclevisnuts

ÿ 2 controlhorntrumpetbases

ÿ 1 trumpetscrew

ÿ 2trumpetclevises.(blackplastic)

ÿ 2tailwheelsteeringsprings

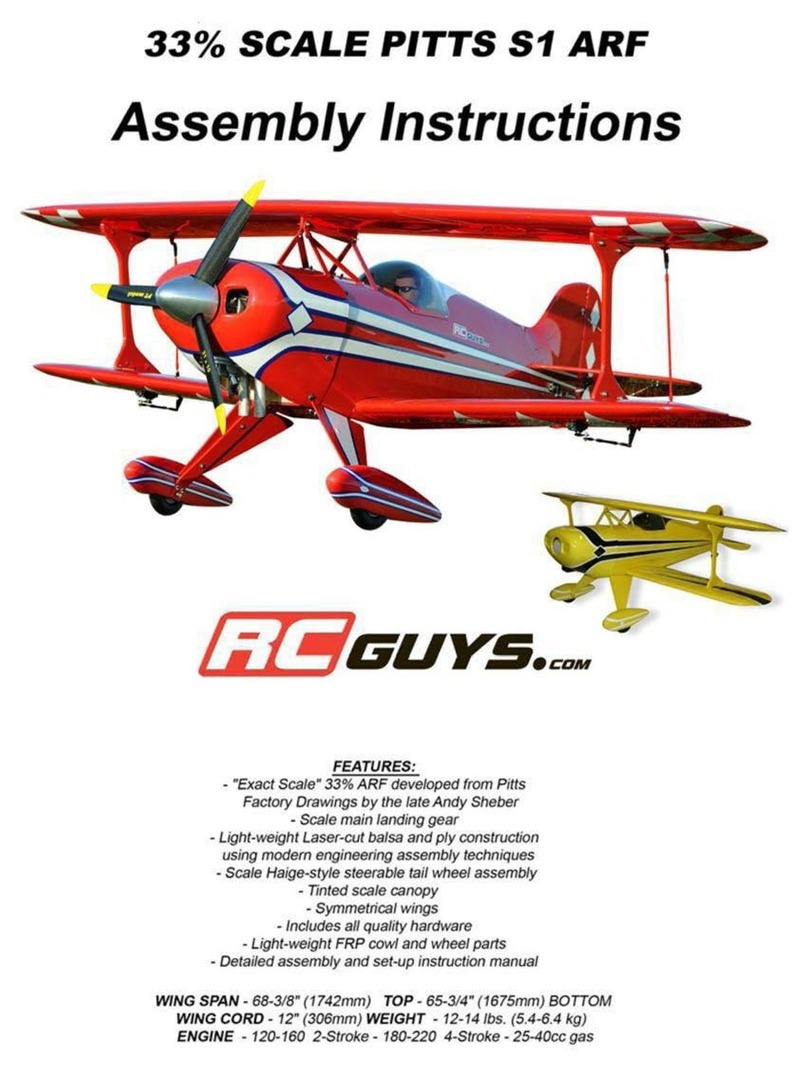

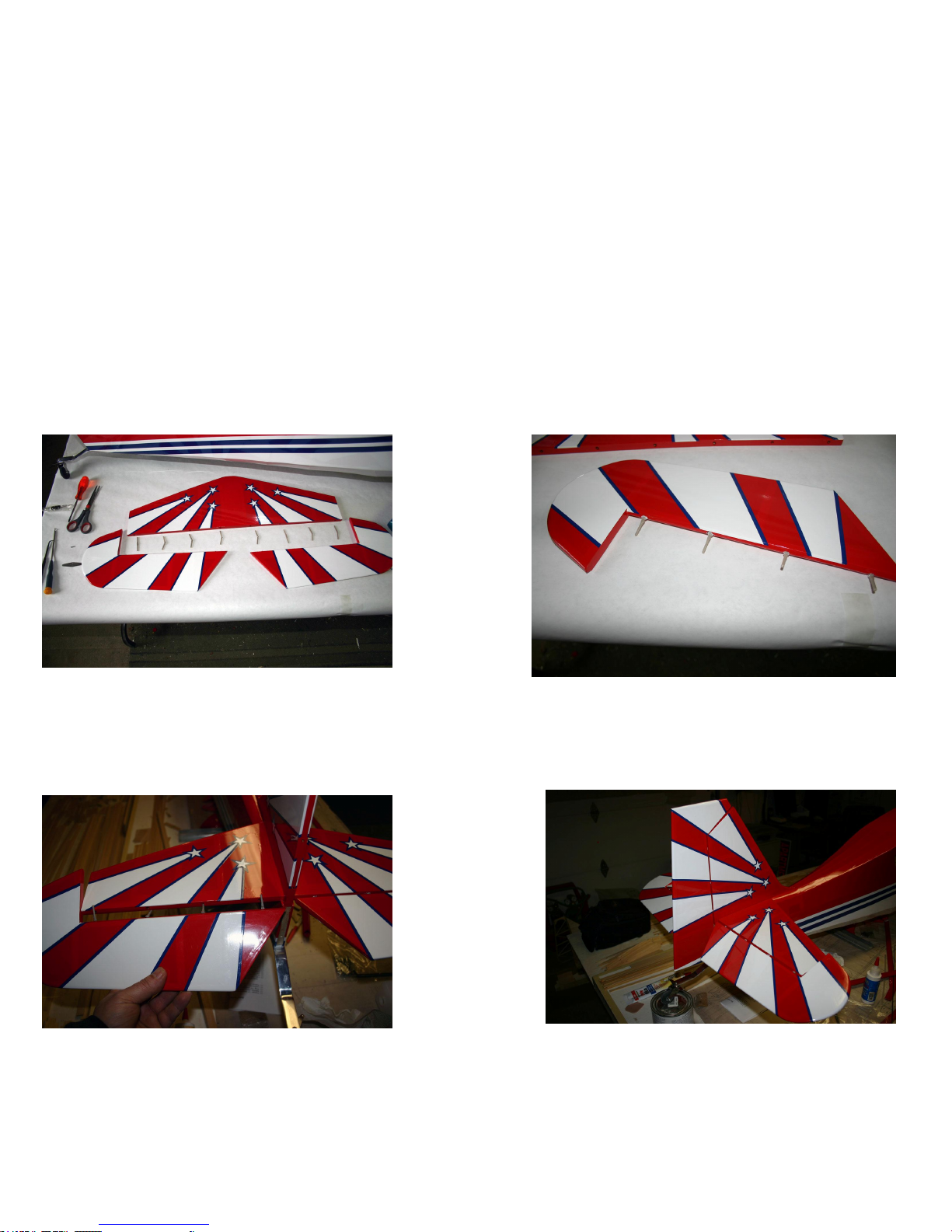

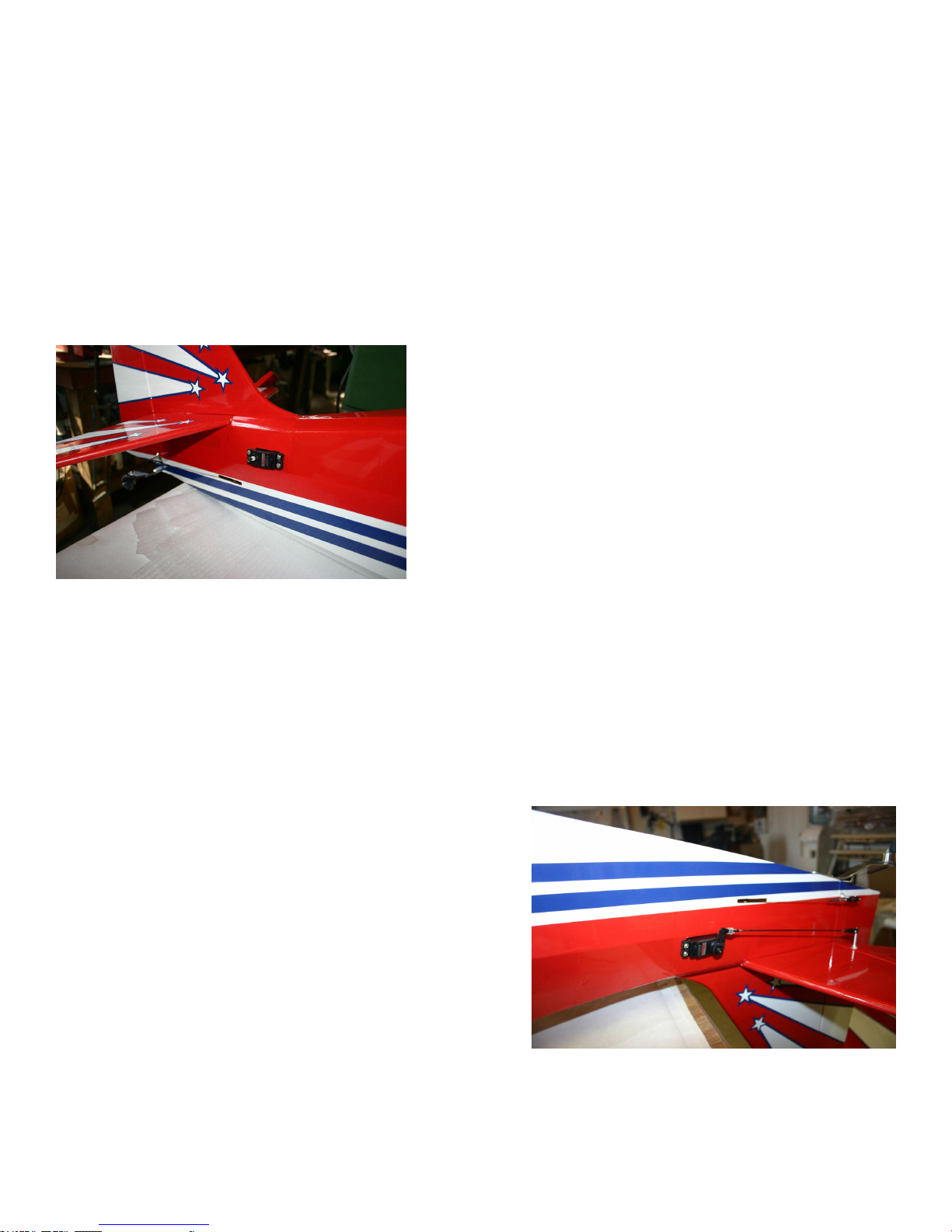

UsingasharpXactoknife,removethecoveringfromtheServoand

pullpullRuddercablecutoutsinbothsidesoftheFuselage.

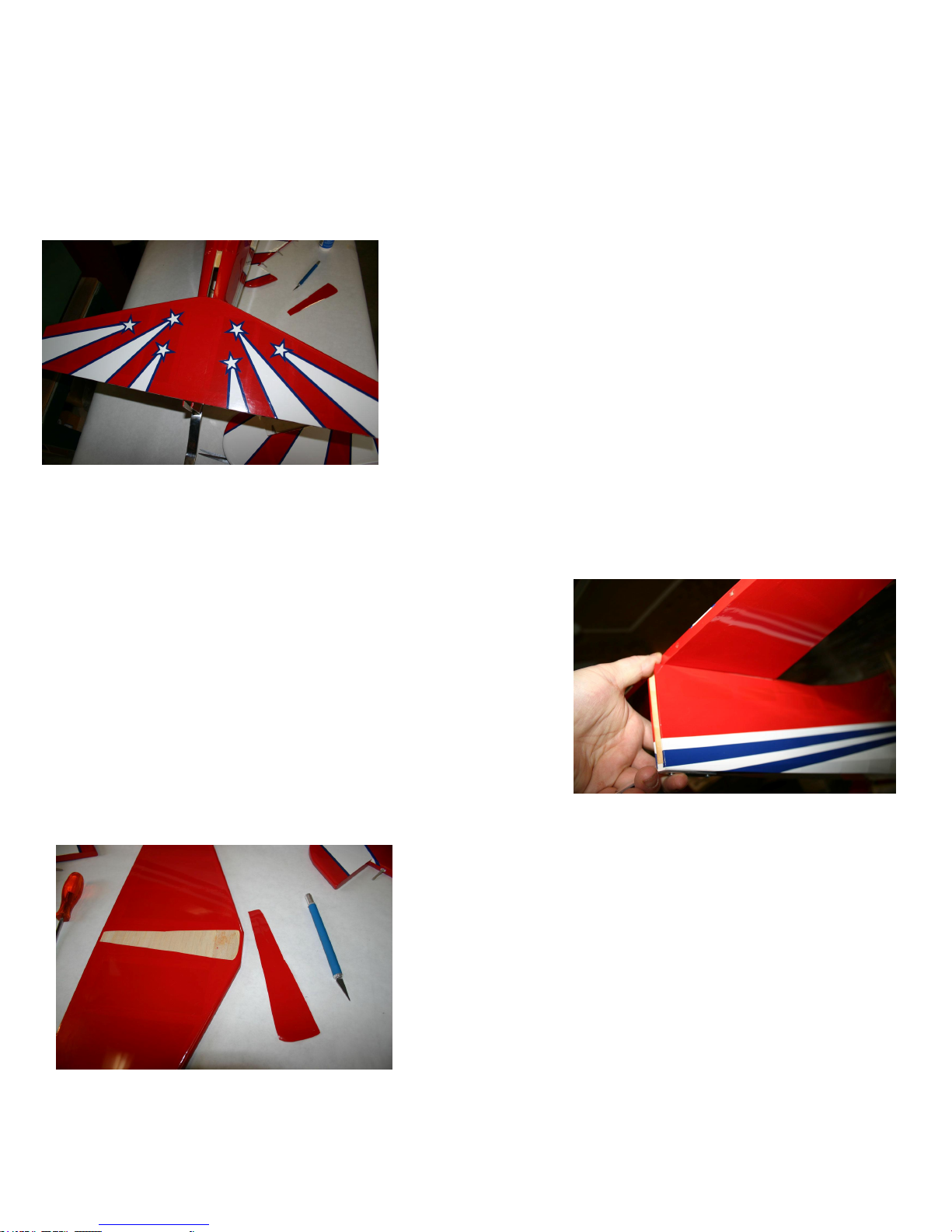

Cutthesuppliedpullpullcableinto2equallengths.Youwillnotice

theyareverylongwhichwillmakeitmucheasiertothreadthroughthe

Fuselagelater.

NOTE:Savethescrappiecesifyouwanttoinstalloptionalflying

wiresfromthestabtoverticalfinonbothsides.

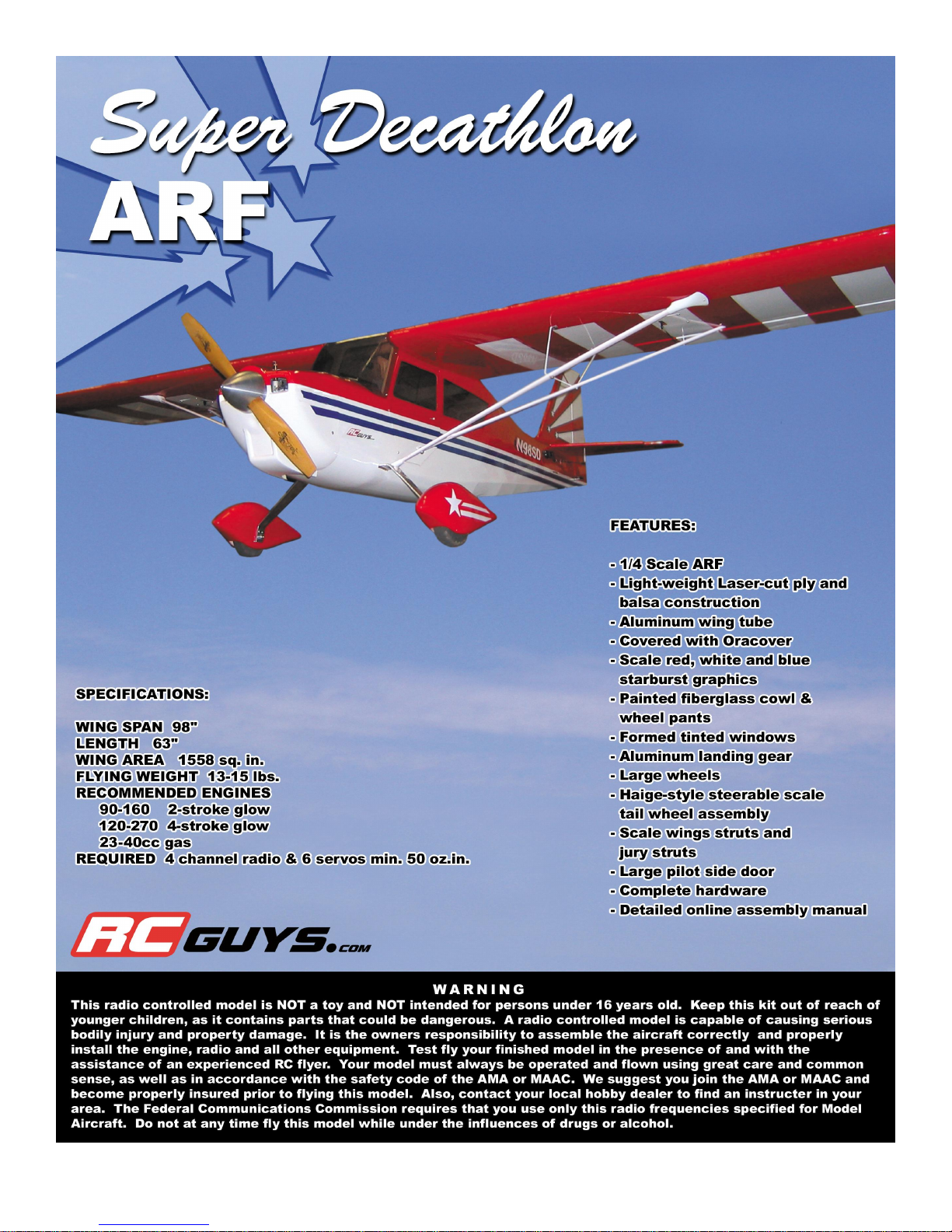

ThreadtheCablethroughthesenewuncoveredholesintherearoftheFuselage.ThreadoneCrimpFittingovertheendof

oneCable,thenthreadtheCablethroughtheouterholeintheyourLargeRudderServoArm.FoldbacktheCable1inch

andslidetheCrimpFittingovertheCableend.Whensatisfiedwiththefit,crimpthefitting.Repeatfortheotherendof

theServoArmwiththeotherCable.

TIP:Usea3/4inchpieceof1/8inchshrinktubingtocoverthesharpendoftheCablestickingoutofthecrimped

jointatbothendsoftheCable.YouwillhavetoslidethisonCableinadvance.

6