Table of Figures

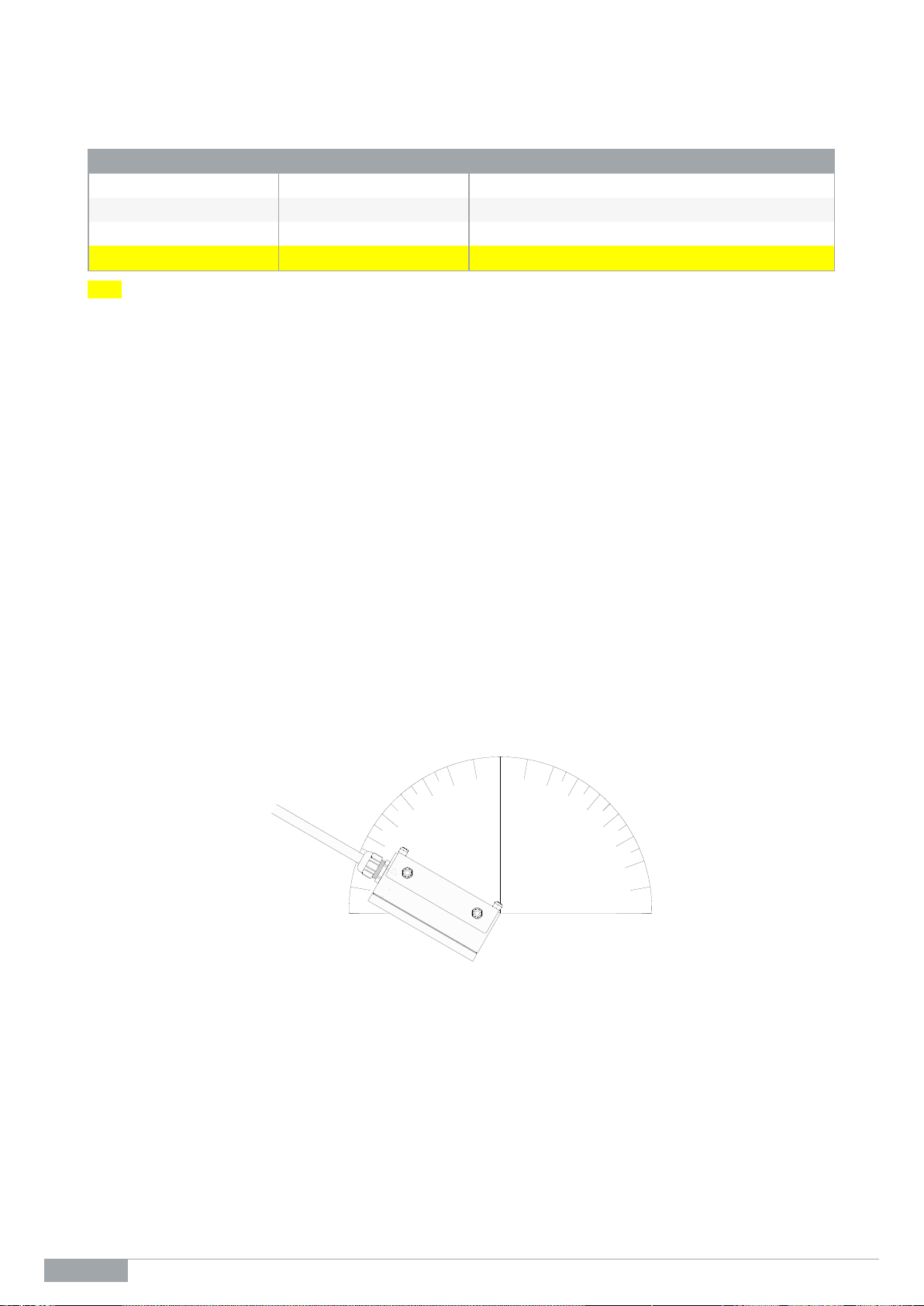

Figure 1 Muirhead® Incline Alarm Shutdown 35-Degree Detect Controller.......................................................5

Figure 2 Drawing 195n –External wiring for energized-to-stop machines........................................................7

Figure 3 Tilting the controller to approximately 35° ± 10°..................................................................................8

General Safety Warnings

Personal Safety

■Everyone is responsible for safety.

■The installer/service personnel should be trained and authorized to complete the required work.

■Ensure that the machine is safely isolated during installation and testing to protect all personnel.

■Complete all required risk assessments and job safety analysis (JSA) before commencing work.

■Observe all site specific and machine OEM procedures regarding the following:

–working at heights

–working in heat

–working in confined spaces

–all other site specific occupational health and safety (OH&S) procedures

Machine

■Carry out all pre-start operations as per site and machine OEM procedures.

■Ensure the machine is safely isolated during installation and testing to protect the machine and other

equipment in the area.

■Do not operate any machine with a known fault and report all findings to the supervisor in writing.

■Test and operate machine as per machine OEM and site procedures.

■Read and understand machine and site specific operational and testing instructions.

Product

Before applying power to the equipment, the user/repairer/installer must read all product instructions. If in

doubt, seek assistance.

■Ensure electrical connections are made as per RCT’s recommendations. Test circuits prior to connecting

power to any component.

■The equipment contains no user serviceable parts inside. Return the unit to RCT for repairs.

■Retain product and installation instructions for future use.

■Ensure that RCT’s recommended service procedures are included in the machine’s service routine.

■Observe all machine, site and RCT product warnings.

■Follow all machine, site and RCT product operating procedures at all time.

The application of safety should not be limited to the above recommendations.