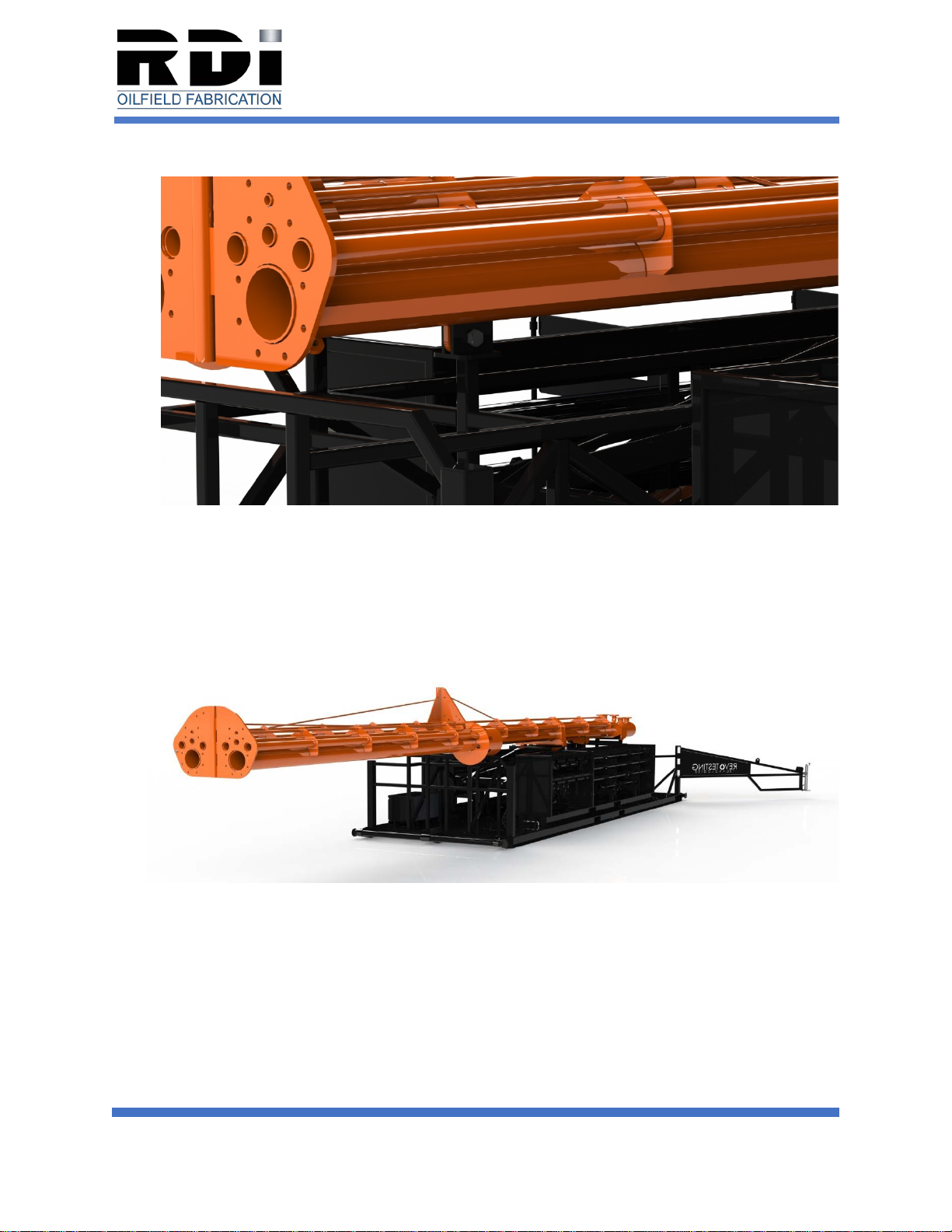

860 FLARE SKID

INSTALLATION AND OPERATION

SPECIAL PRECAUTIONS

WARNING: Failure to comply with the general safety information may result in

extensive property damage, severe personal injury or death.

WARNING: Do not alter or damage the unit. Severe personal injury or death may

occur.

Follow all installation and operation instructions CAREFULLY to avoid creating unsafe

conditions. All wiring should be done and checked by a qualified electrician. All gas

connections should be made, and leak tested, by a suitably qualified individual per

instructions in this manual. Follow all procedures listed in “Standard Operating

Procedures” located in this manual.

WARNING: Disconnect all power and gas supplies before servicing the unit. Failure to

do so could result in fatal electric shock or severe personal injury.

WARNING: Do not insert fingers or other objects into electrical compartments of the

unit. Do not block or tamper with the unit in any manner while in operation or

immediately following the unit being turned off. Some parts may be hot enough to

cause injury.

This unit has multiple pinch point hazards. Exercise extreme caution when working on

or around this unit and avoid placing fingers or extremities in these locations.

Pipe being stored or shipped on this trailer needs to be secured with pins prior to travel.

Do not attempt to move flare skid in standing position.

Prior to towing or moving the skid, insert and double-check that all bolt locking

mechanisms are installed to secure the flare stack, outriggers and jacks. Jacks need to

be perpendicular to the trailer frame before travel. Outriggers need to be in closed

position before travel.

Ensure that safety pin at headache rack for flare pipe ins pinned during unpacking and

unpinned during lifting to assist with side torque.

Before raising or lowering the stack, the REMOVABLE SKIDS MUST BE FULLY

LOADED AND PINNED INTO PLACE on the main skid.