Page 9SpecicationsPage 8 Igea Motor Installation Page 9Igea Motor Installation

12. Repeat these steps for the other leaf, if installed

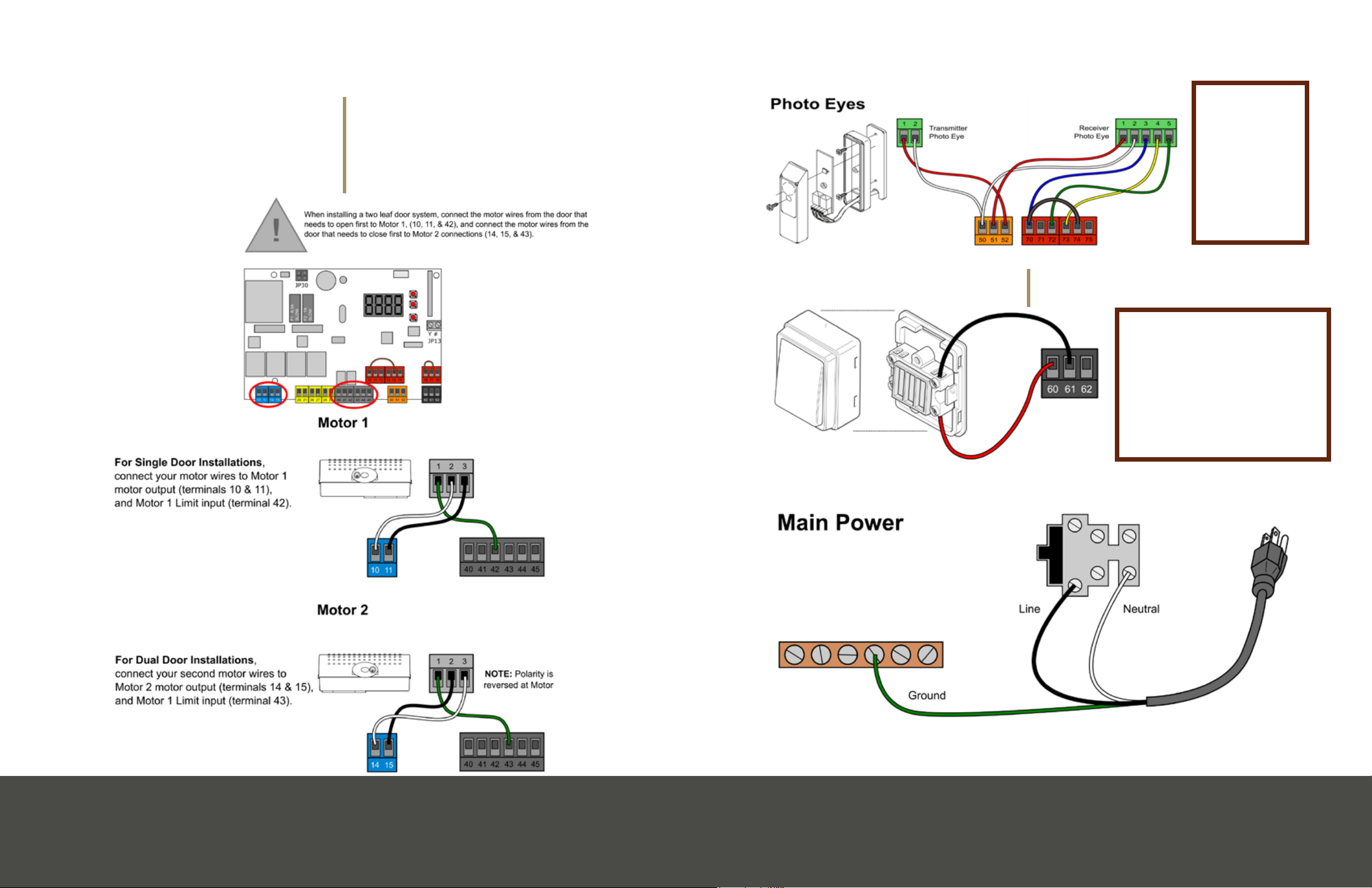

Wiring the Motor

1. Locate the stress relieving cord-grip

2. Attach connecting nut (F) to grip body (G).

Tighten securely using nger pressure only

3. Slip compression nut (H) over a length of 16/3

(16 Gauge, 3 strand) motor wire and thread wire

through the assembled cord-grip

4. Tighten the compression nut (H) with nger

pressure only

5. Refer to Wiring Simplied for wiring from motor

to control board terminals

Installing the Limit Switches

1. Install the full cam on top of the metal shaft

• Then install the ring cam on top of the full cam

• Do not fully tighten the xing screws.

2. When the door

is fully open,

rotate the

corresponding

cam (g.

4), until you

hear a ‘click’

indicating the limit switch has been depressed

• Lock it in position by tightening the appropriate

screws

• Repeat for the fully closed position

• Refer to “Manual Operation Mode” to manually

swing the door.

3. Swing the door slowly to its open and close

positions, listening to see that the ‘click’ of the

limits switch occurs where desired

Note: that the left motor’s cams (close vs open) are

inverted from those of the right motor. Adjust as

necessary

Left Motor (as viewed from inside)

Stop Position Cam Position

Close Top

Open Bottom

Right Motor (as viewed from inside)

Stop Position Cam Position

Close Bottom

Open Top

Installa�onofLimitSwitches

1.Installthelimitswitchreferncecamsas

showning.3.Installthefullcamontopof

themetalsha,theninstalltheringcamon

topofthefullcam.Donotfullyghtenthe

xingscrews.

2.Whenthedoorisfullyopen,rotatethe

correspondingcam(g.4),unlyouheara

‘click’indicangthelimitswitchhasbeen

depressed,thenlockitinposionby

ghteningtheappropriatescrews.Repeatfor

thefullyclosedposion.Referto“Manual

OperaonMode”tomanuallyswingthedoor.

3.Swingthedoorslowlytoitsopenandclose

posions,listeningtoseethatthe‘click’of

thelimitsswitchoccurswheredesired.Adjust

asnecessary.

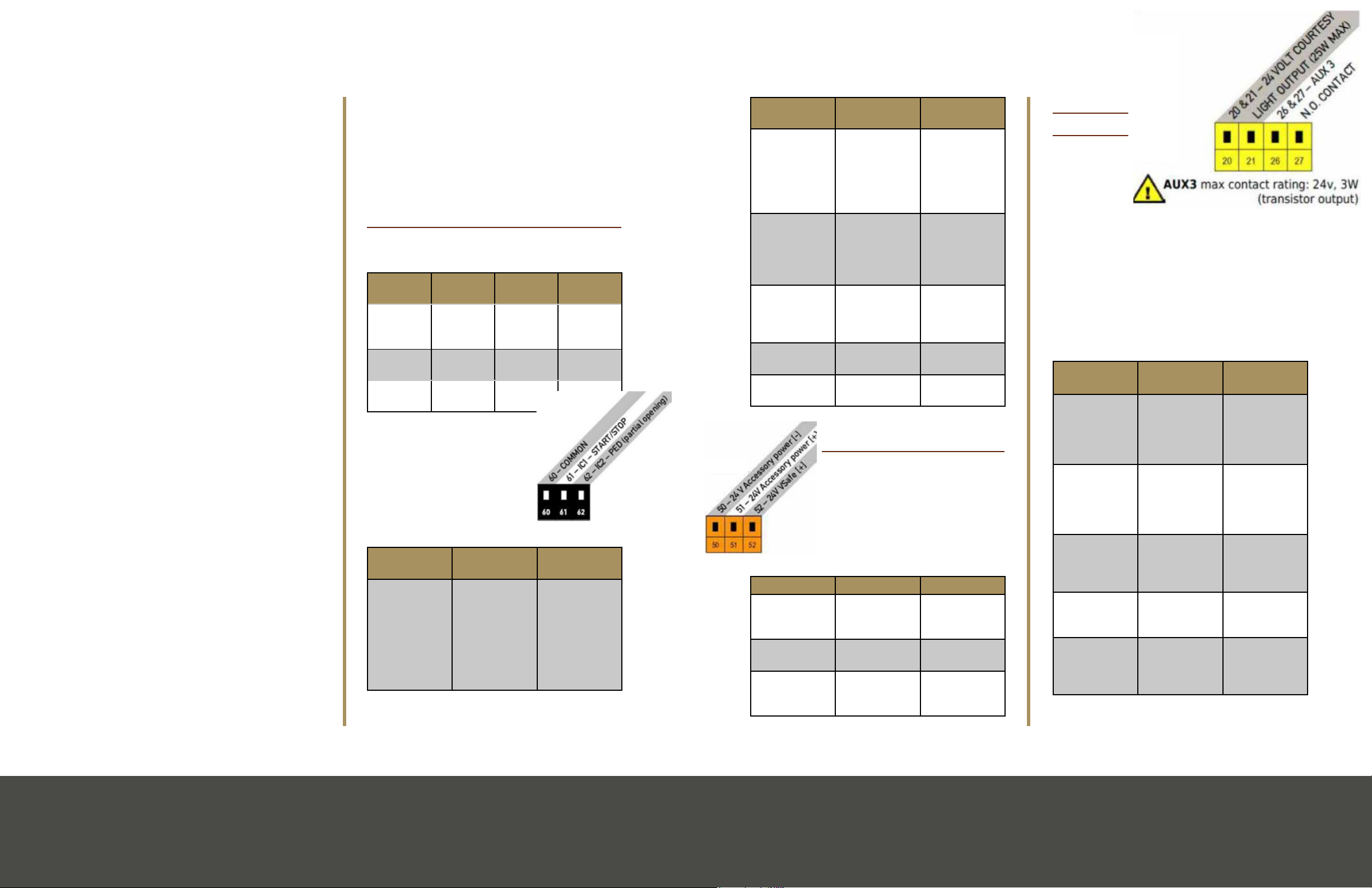

Fig4.LimitSwitchfuncons

LEFTMOTOR

(viewedfrominside)

RIGHTMOTOR

(viewedfrominside)

CLOSELIMITCAM

OPENLIMITCAM

CLOSELIMIT

SWITCH

OPENLIMIT

SWITCH

OPENLIMITCAM

CLOSELIMIT

OPENLIMIT

SWITCH

CLOSELIMIT

SWITCH

Fig3.LimitSwitchinstallaon

FULLCAMRINGCAM

Franklin Autoswing Installation Manual

TM

© 2012 Copyright Real Carriage Door Company, Inc

Igea Motor Installation

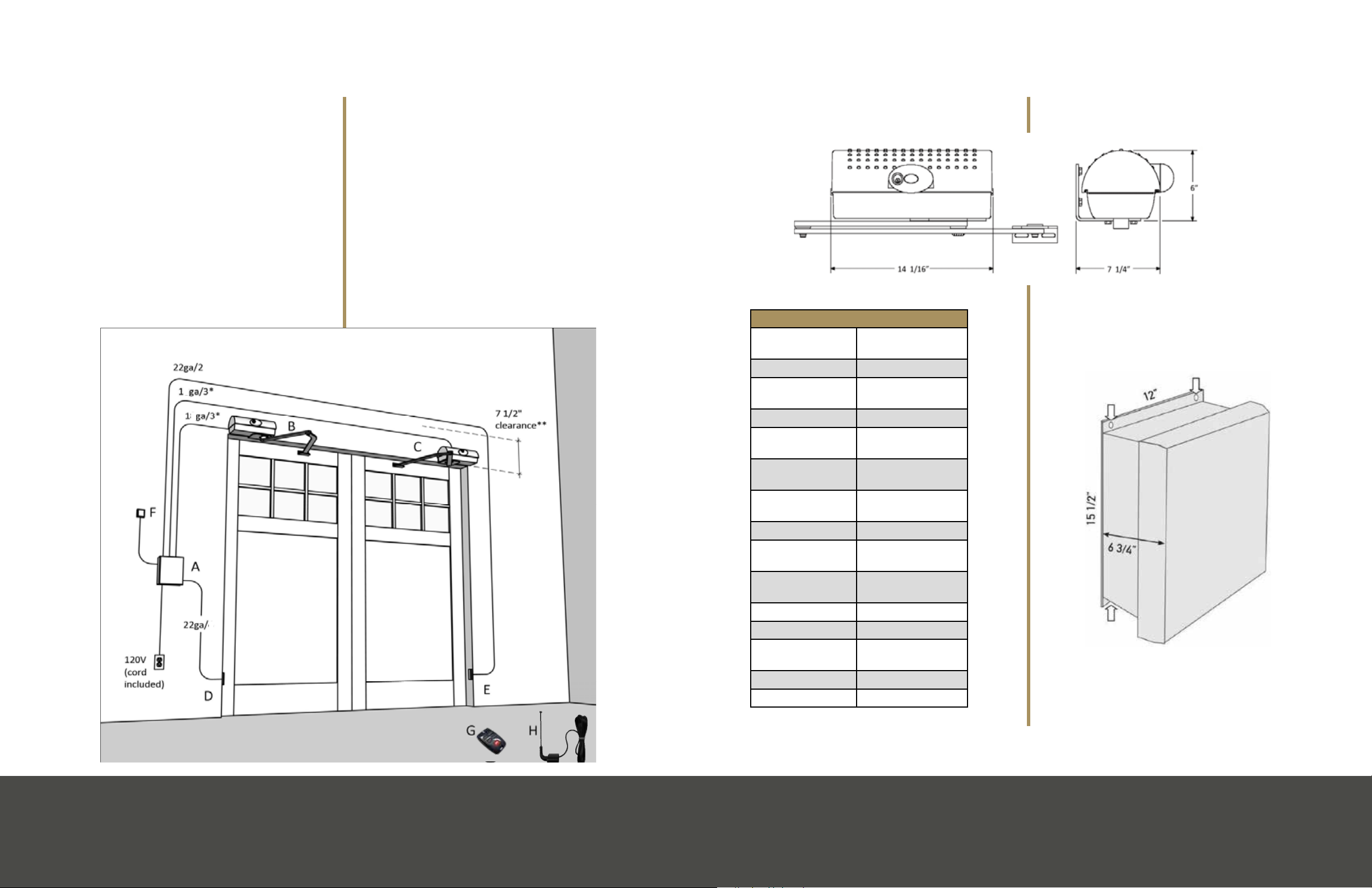

TIP: Before mounting, refer to “Typical System

Overview” for prewiring.

• For a very ‘clean’ installation, mount the unit

directly on the head casing (if at prole)

• This motor positioning is for outswing doors

only

1. Remove the cover from the motor and set aside

2. Remove the motor from the base plate by

loosening the 4 bolts on the bottom of the motor

3. Position the base plate (note that body of the

motor should extend toward the side jamb) about 7”

from the edge of the door*

• Level the plate and mark the locations of the

holes.

• TIP: For most applications, centering the

bottom row of holes on the jamb makes for the

most secure installation.

NOTE: See page 37 for arched door applications.

4. Level and mount the plate with minimum 3/8” x

4” lag bolts (not supplied)

• For proper arm clearance, the bottom of the

plate must no higher than the lowest part of the

jamb

• Always make certain that the lag bolts penetrate

solid header and/ or

blocking material

5. Re-attach the motor to

the base plate and tighten

securely. Be sure that the

motor is seated properly in

its plastic housing

6. Assemble the articulated

lever arm and door coupling as

shown in g. 1.

• Connect straight arm and door coupling to

curved arm using plastic sleeve (K) and washer

(L)

• Secure together with rolled pin (M). The

dashed arm indicates the setup for the right

motor (viewed from inside)

7. Slide the assembled arm onto the transmission

shaft at the base of the motor

• Fasten it using the long pin (N) and C-ring (O)

8. Manually release the operator (See “Manual

Operation Mode”)

9. Open the door to the desired ‘fully open’ point

(approximately 105 degrees is recommended)

• With a measuring tape, mark the centerline

of the door mounting bracket at 40” from the

center of the

shaft (g. 2)

• Making sure that

the arm is level,

Mount the arm

to the door with

#14 x 1-1/2” pan

head screws

(not supplied)

10. Check clearance

and movement by

swinging door slowly

11. Relock the motor

(take out of manual

release mode)

1.Removethecovertothemotorandsetaside.

2.Removethemotorfromthebaseplatebylooseningthe4boltsontheboomofthemotor.

3.Posionthebaseplate(notethatbodyofthemotorshouldextendtowardthesidejamb)about7”fromtheedge

ofthedoor*.Leveltheplateandmarkthelocaonsoftheholes.TIP:Formostapplicaons,centeringtheboom

rowofholesonthejambmakesforthemostsecureinstallaon.

Lebaseplateposion,squaretop

door(interiorview)

Installa�onofMotor

TIP:Beforemounng,referto“TypicalSystemOverview”forprewiring.Foravery‘clean’

installaon,mounttheunitdirectlyontheheadcasing(ifatprole).Notethatthismotor

posioningisforoutswing doors only.

4.Levelandmounttheplatewithminimum3/8”x4”lagbolts(notsupplied).Forproperarmclearance,theboom

oftheplatemustnohigherthanthelowestpartofthejamb.Alwaysmakecertainthatthelagboltspenetratesolid

headerand/orblockingmaterial.

5.Reaachthemotortothebaseplateandghtensecurely.Besurethatthemotorisseatedproperlyinitsplasc

housing.

*NOTE: There are limita�ons for certain arch‐top radii rela�ve to the door width. See table in

APPENDIX C for allowable radii, and APPENDIX D for more help in posi�oning.

Lebaseplateposion,archtop

door(interiorview)

7”

7”

Franklin Autoswing Installation Manual

TM

© 2012 Copyright Real Carriage Door Company, Inc

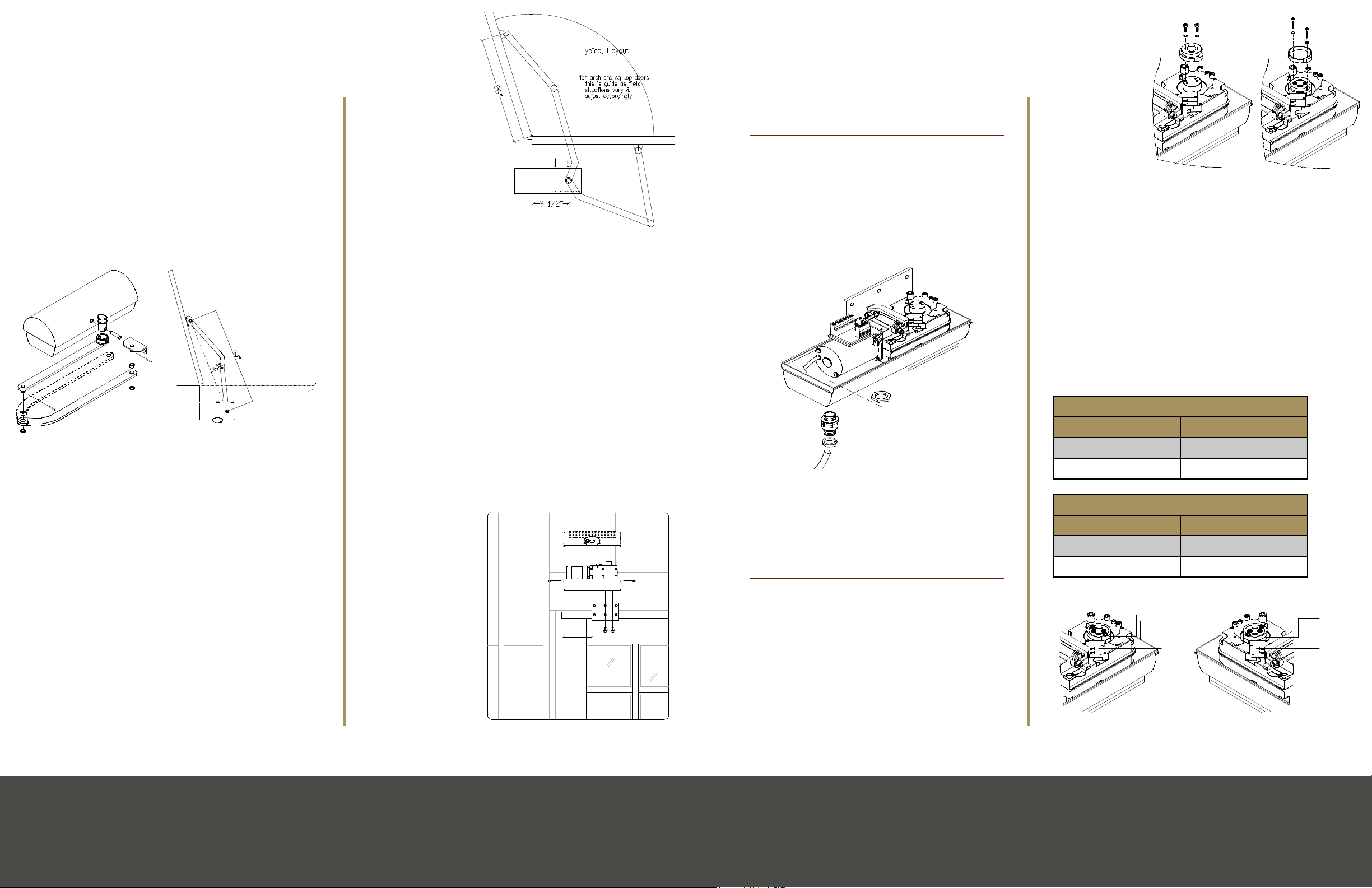

6.Assemblethearculatedleverarmanddoorcouplingasshowning.1.Connectstraightarmanddoorcouplingto

curvedarmusingplascsleeve(K)andwasher(L).Securetogetherwithrolledpin(M).Thedashedarmindicates

thesetupfortherightmotor(viewedfrominside).

7.Slidetheassembledarmontothetransmissionshaatthebaseofthemotor,andfastenitusingthelongpin(N)

andCring(O).

8.Manuallyreleasetheoperator(See“ManualOperaonMode”).

9.Openthedoortothedesired‘fullyopen’point(approx105degreesisrecommended).Withameasuringtape,

markthecenterlineofthedoormounngbracketat40”fromthecenterofthesha(g.2).Makingsurethatthe

armislevel,Mountthearmtothedoorwith#14x11/2”panheadscrews(notsupplied)

10.Checkclearanceandmovementbyswingingdoorslowly.

11.Relockthemotor(takeoutofmanualreleasemode).

12.Repeatthesestepsfortheotherleaf,ifinstalled.

Installa�onofMotor(Con�nued)

Fig1.ArmAssemblyFig2.Armposioning

K

L

M

N

O

NOTE:

1.5” is minimum allowable arm

bend. Distances over 1.5” are

acceptable.

TM

Franklin Autoswing Installation Manual

© 2012 Copyright Real Carriage Door Company, Inc

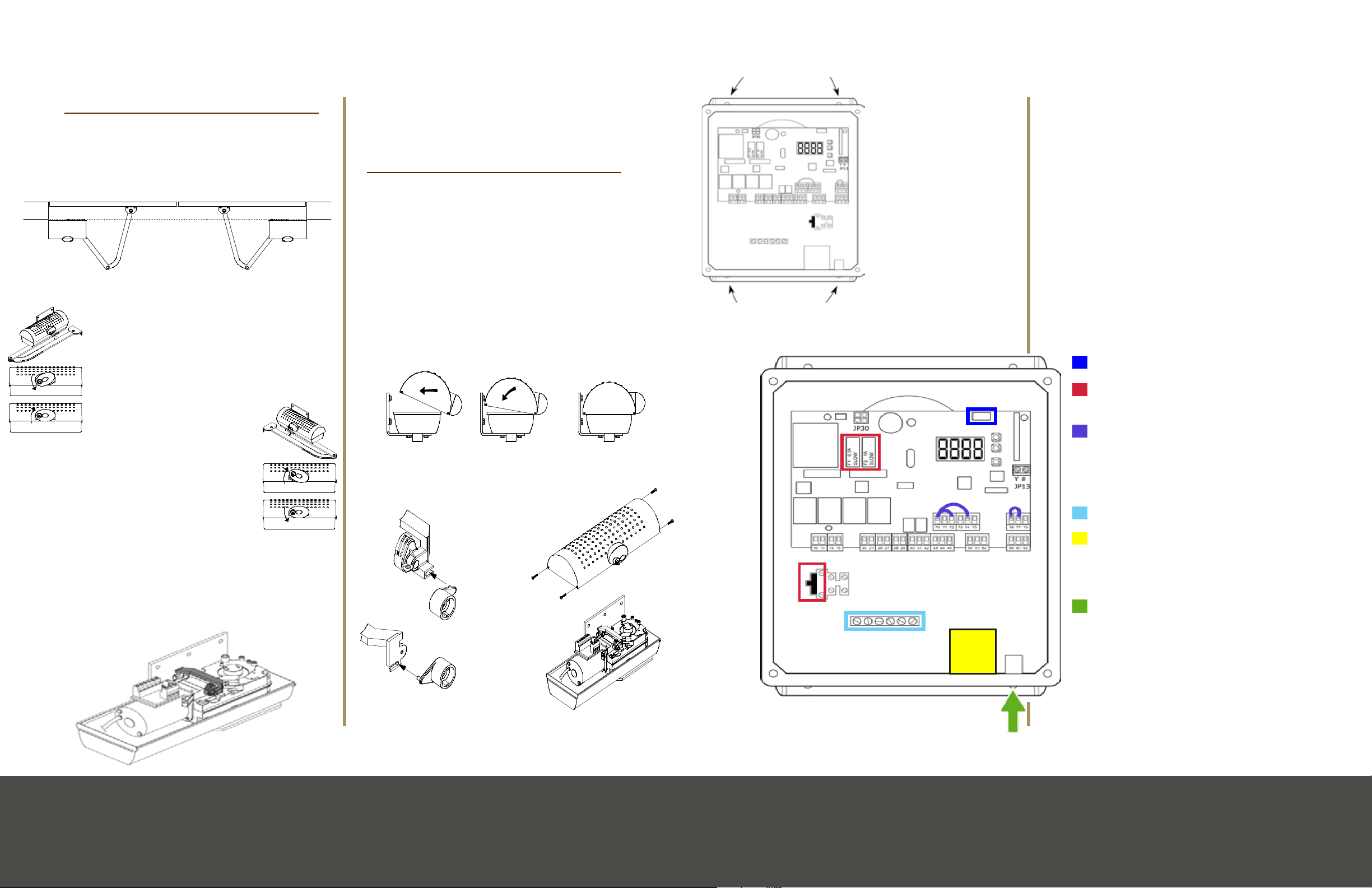

1.LocatethecontrolhousingcontainingtheLIBRAULRpanel.

2.Formounng,therearofthehousingmustbepredrilled.Refer

tog.5forthelocaonsoftheholestobedrilled.

3.Atthisme,planwhereyouwouldliketorunthewiringinto

thehousingandpredrillforstressreliefconnectors.Be careful

not to damage the panel when drilling into the housing! It is a

good idea to remove the panel while drilling.

4.Mountthehousingsecurely,usingeitherscrewsordrywall

anchors(notsupplied).Becarefulnottodamageanywiresor

componentsoftheboard.(See“TypicalSystemOverview”for

suggestedlocaonofthehousing)

Moun�ngtheControlHousing

Fig5.Mounnglocaons

Fig6.Stressreliefconnector

1.Locatethestressrelievingcordgrip.

2.Aachconnecngnut(F)togripbody(G).Tightensecurely

usingngerpressureonly.

3.Slipcompressionnut(H)overalengthof18/3(18Gauge,

3strand)motorwireandthreadwirethroughthe

assembledcordgrip.

4.Tightenthecompressionnut(H)withngerpressureonly.

5.Referto“MasterWiringDiagram”towirethemotortothe

LIBRAULRcontrolpanel.

6.Forbasicprogrammingsee“GeneralProgramming.”For

advancedparameters,pleaseseetheBFT“LIBRA‐UL‐R

Installa�on and User’s Manual”

WiringtheMotor

F

G

H

WIRE USE

min18/3wire*connecngmotorstocontrolpanel

min22/4wireconnecngRXphotoeyetocontrolpanel

min22/2wireconnecngTXphotoeyetocontrolpanel

*Use stranded wire. Increase gauge if motors more than 20’ from panel

TM

Franklin Autoswing Installation Manual

© 2012 Copyright Real Carriage Door Company, Inc

Installa�onofLimitSwitches

1.Installthelimitswitchreferncecamsas

showning.3.Installthefullcamontopof

themetalsha,theninstalltheringcamon

topofthefullcam.Donotfullyghtenthe

xingscrews.

2.Whenthedoorisfullyopen,rotatethe

correspondingcam(g.4),unlyouheara

‘click’indicangthelimitswitchhasbeen

depressed,thenlockitinposionby

ghteningtheappropriatescrews.Repeatfor

thefullyclosedposion.Referto“Manual

OperaonMode”tomanuallyswingthedoor.

3.Swingthedoorslowlytoitsopenandclose

posions,listeningtoseethatthe‘click’of

thelimitsswitchoccurswheredesired.Adjust

asnecessary.

Fig4.LimitSwitchfuncons

LEFTMOTOR

(viewedfrominside)

RIGHTMOTOR

(viewedfrominside)

CLOSELIMITCAM

OPENLIMITCAM

CLOSELIMIT

SWITCH

OPENLIMIT

SWITCH

OPENLIMITCAM

CLOSELIMITCAM

OPENLIMIT

SWITCH

CLOSELIMIT

SWITCH

Fig3.LimitSwitchinstallaon

FULLCAMRINGCAM

Franklin Autoswing Installation Manual

TM

© 2012 Copyright Real Carriage Door Company, Inc