Table of Contents

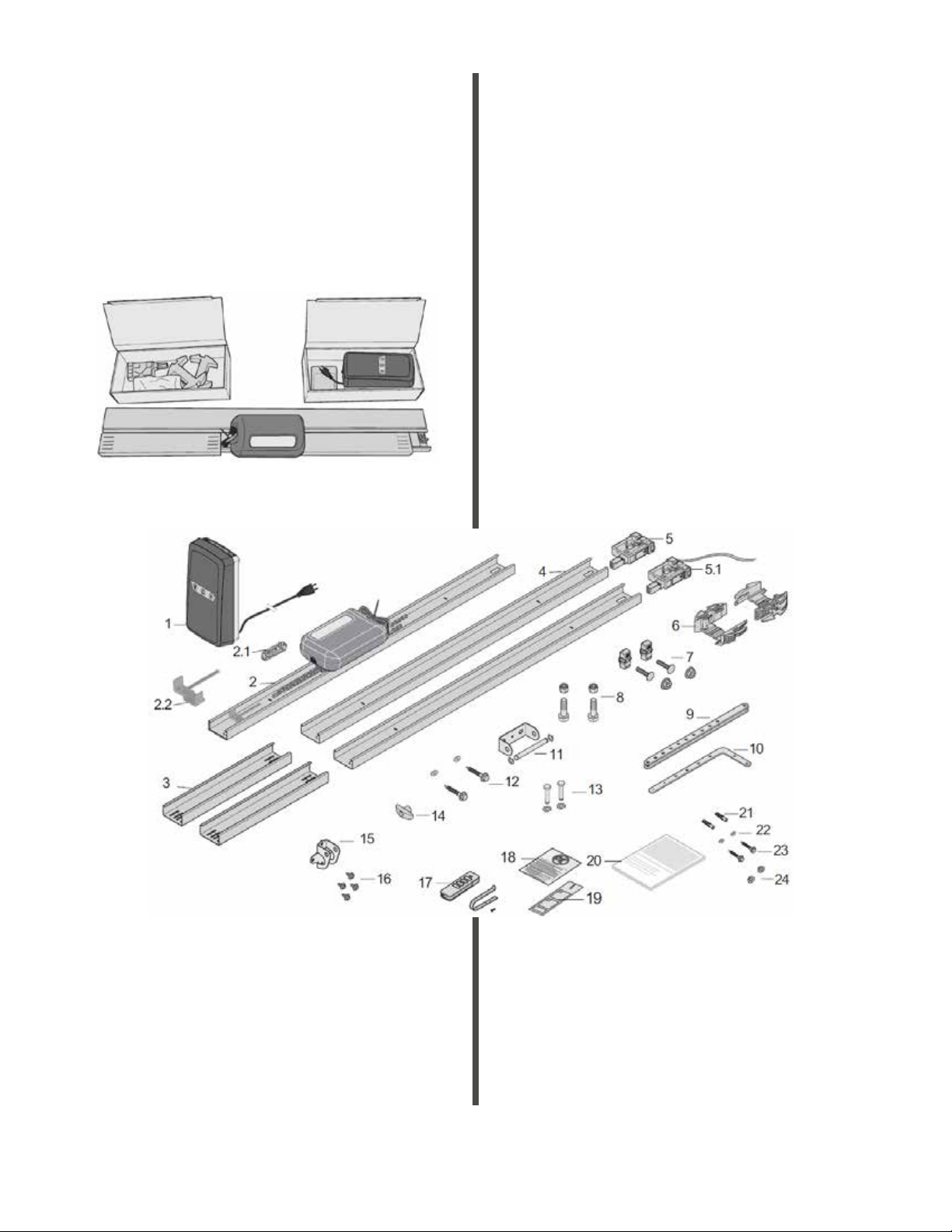

Packaging ........................................................................................................................4

Specications ..................................................................................................................6

• Motor Carriage.....................................................................................................................................................................8

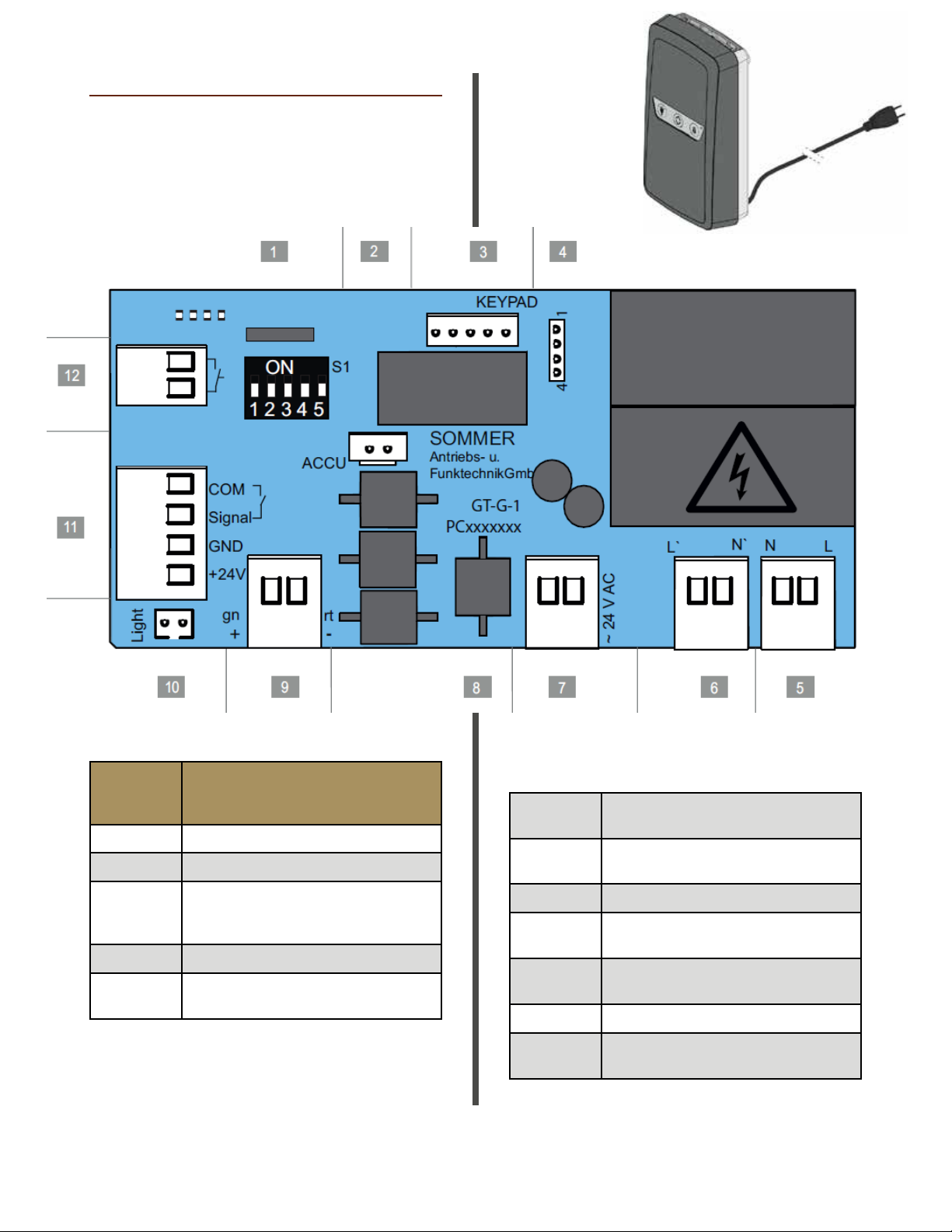

• Control Unit ..........................................................................................................................................................................10

System Overview..............................................................................................................12

Installation Instructions....................................................................................................14

• Connecting the rails............................................................................................................................................................14

• Chain Tensioner ................................................................................................................................................................. 14

• Wire Connector.................................................................................................................................................................... 15

• Ceiling Bracket.....................................................................................................................................................................16

• Attaching the Swing Arm Fitting......................................................................................................................................16

• Header Brackets..................................................................................................................................................................17

• Push Rods ............................................................................................................................................................................18

• Mounting Control Unit........................................................................................................................................................19

• Inserting ACCU (battery backup) .....................................................................................................................................20

Photo Eyes .......................................................................................................................21

Autoset Programming ......................................................................................................22

• Red Limit Stop ..................................................................................................................................................................... 22

• Autoset..................................................................................................................................................................................23

After Autoset Completion .................................................................................................24

• Battery Pack (ACCU) Installation ..................................................................................................................................... 24

• Adjusting the Close Limit ..................................................................................................................................................24

• Troubleshooting.................................................................................................................................................................. 24

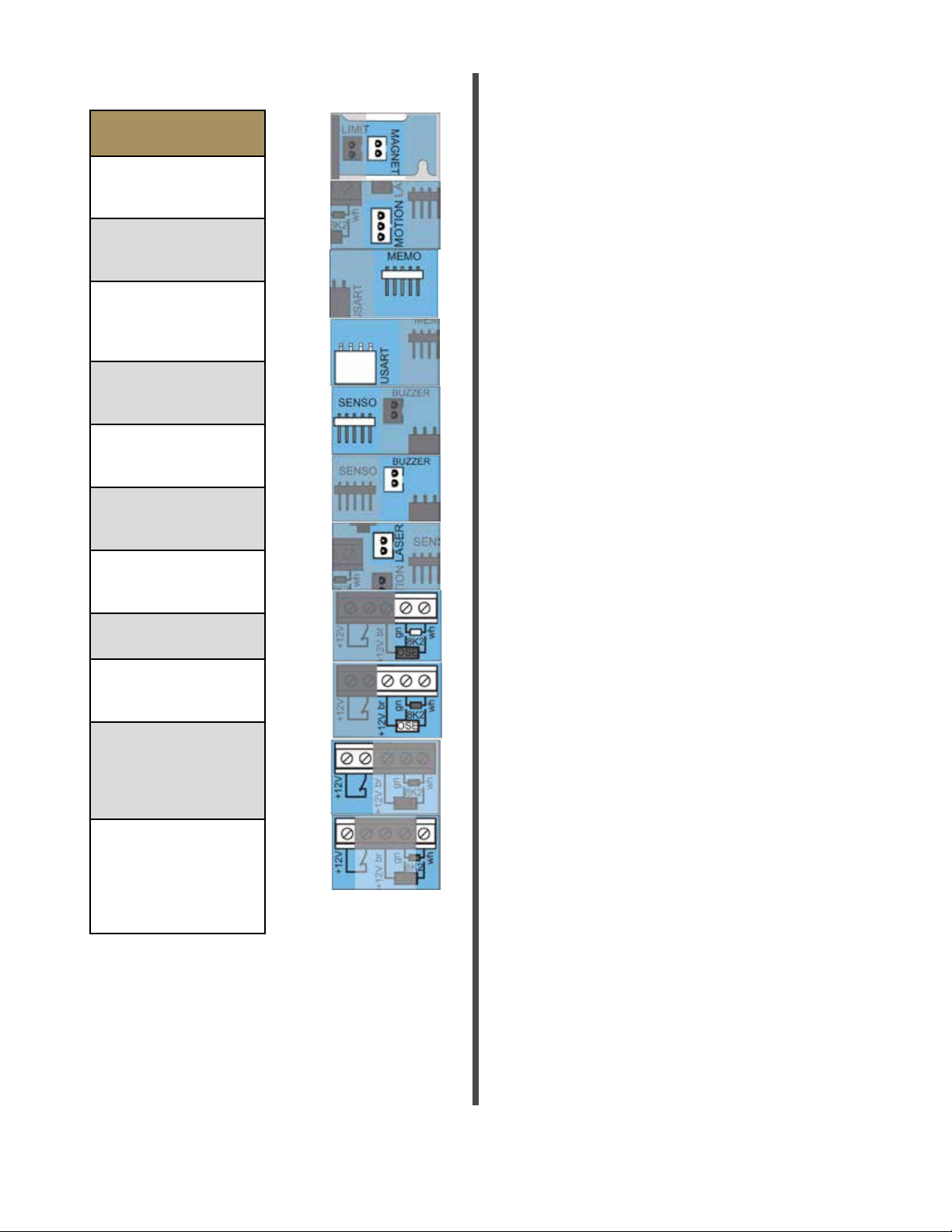

Accessories .....................................................................................................................25

• Remotes ...............................................................................................................................................................................25

• Homelink...............................................................................................................................................................................25

• Battery Pack.........................................................................................................................................................................26

• MEMO....................................................................................................................................................................................26

• SOMLINK ..............................................................................................................................................................................26

• SOMweb............................................................................................................................................................................... 27

• SENSO...................................................................................................................................................................................27

• Outdoor Keypad ..................................................................................................................................................................27

• Wireless Wall Control .........................................................................................................................................................28

Maintenance and Care......................................................................................................28