Contents

Installation Instructions Page

Important notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What the installer willneed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Where to locatetheSB² . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing thewater supply andsteamvent pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing themainssupply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

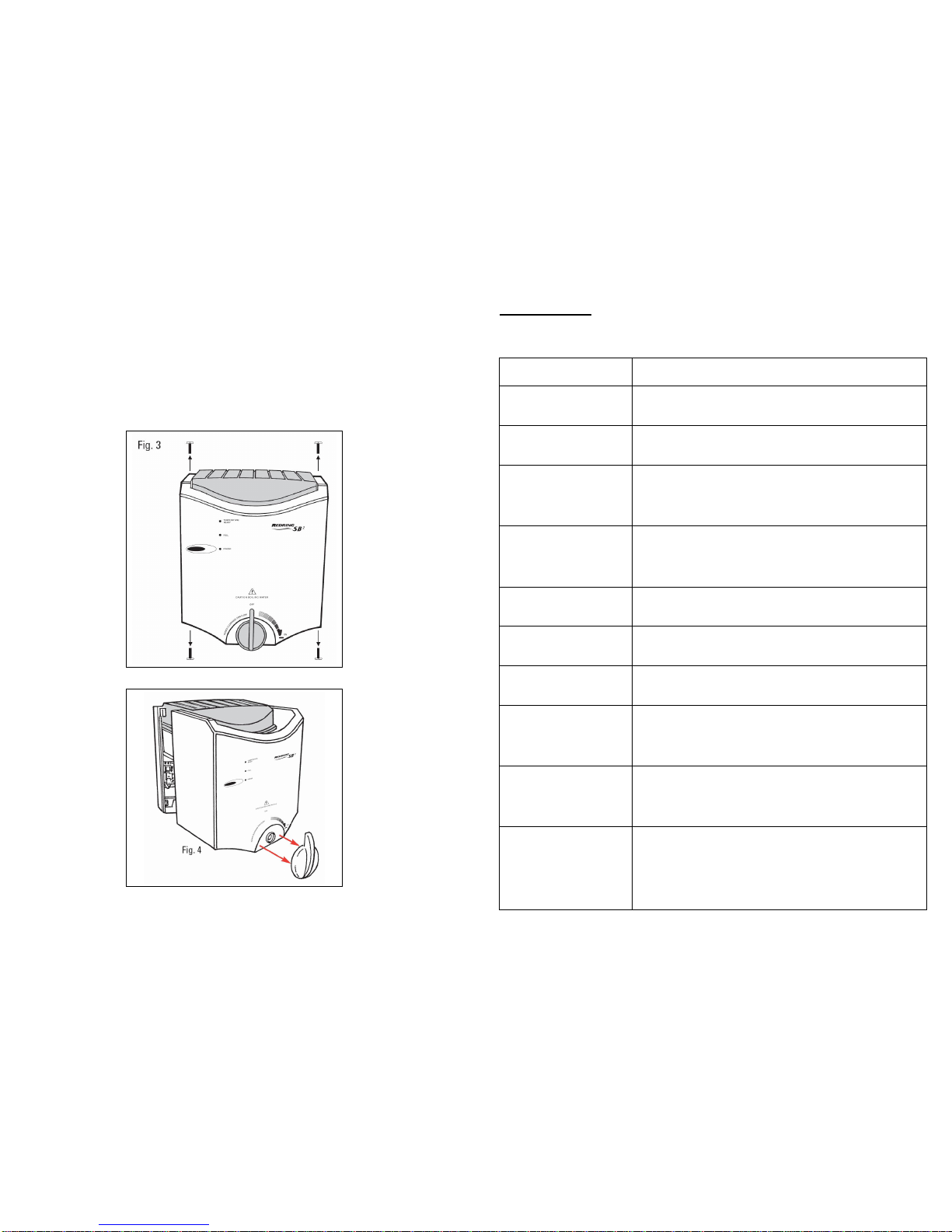

Removingthe front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fixingthe unit onthewall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting the water supplyandsteamvent pipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting the mainscable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Replacing the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Schematicwiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Instructions

General product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How tooperate the SB² . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How toclean and descale your SB² . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Trouble shootingguidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

After SalesService . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Thankyou for choosing aquality Redring product manufactured in Peterborough, England

Installation Instructions

Important Notes

•This appliance is intended to be used in household and similar applicationssuchas: -

-staff kitchenareas in shops, offices and other working environments;

- farm houses;

- byclients in hotels, motels and other residential type environments;

-bed and breakfast typeenvironments.

•All installations mustbe undertaken bya competent installer.

If in anydoubt, advice and assistance should besought from aqualified plumber

and/or electrician.

•Installation and wiring must conf

orm to the current BS.7671 (IEE Wiring Regulations)

and the Water Fitting Regulations. Local regulations mayapply in other countries.

•The steam vent connection MUST BE MADE, as required in these instructions.

•A means fordisconnection in all poles must be incorporated in thefixed wiring in

accordance with the wiring rules.

•

Check that the mainssupplymatches the electrical rating on theproduct.

The rating plate is located on thebottom edgeof the unit.

•Frost Protection: This appliance should be located wherethe ambient air temperatureis

between 5°C and 50°C. If the temperaturemayfall below 5°C when the appliance is not in

use, do not turn off the applianceelectrically. This safeguard does NOT offer protection to

the connecting pipe work and fittings. The unit should not be operated if freezing is

suspected. Allow the unit to thaw completely.

•This unit must not be cleaned by, or installed in an areacleanedby, awater jet.

•THIS APPLIANCE,AND ALL METAL PIPEWORK CONNECTED TO IT, MUSTBE EARTHED.

•If you have anyqueriesabout installing thisproduct or after it has been installed, please

contact ourCustomerService Helpline on 0844372 7766

Customersoutsidethe U.K. should contact their local distributor.

•This product mayneed to be descaled regularly.

The frequencyof descaling will depend on the hardness of the watersupply.

Redring After Sales Service

Weoffer a technical advisory serviceon the telephone to contractors andother customers with

problems in the field.

RING0844 372 7766

Some partscan be supplied against Credit or Debit cards.

RING0844 372 7750

Remember to quote theexact model of SB² unit, aswritten on the front of the unit and on thisleaflet.

It may also be of use tohavea note of the model and serial number asstated on theunderside of the

unit.

Spare Parts

Part Number Part Description

95-719601

95-719613

95-719614

95-719615

95-719616

95-719617

95-719618

95-719608

95-719609

95-719619

95-719611

95-719620

Element assembly

Terminal block

Logic boardassembly

Power PCB assembly

Solenoid valve

Float switch

Cable pack

Control knob

Outlet spout

Scaletrap

Outlet valve

Inlet elbow assembly (includesflow regulator)

Thisappliance isnot intended for use by persons (including children and theinfirm) with

r

educed physical, sensoryor mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of theappliance

by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.