7

MAX®S-Series LED Installation & Operation Manual’s

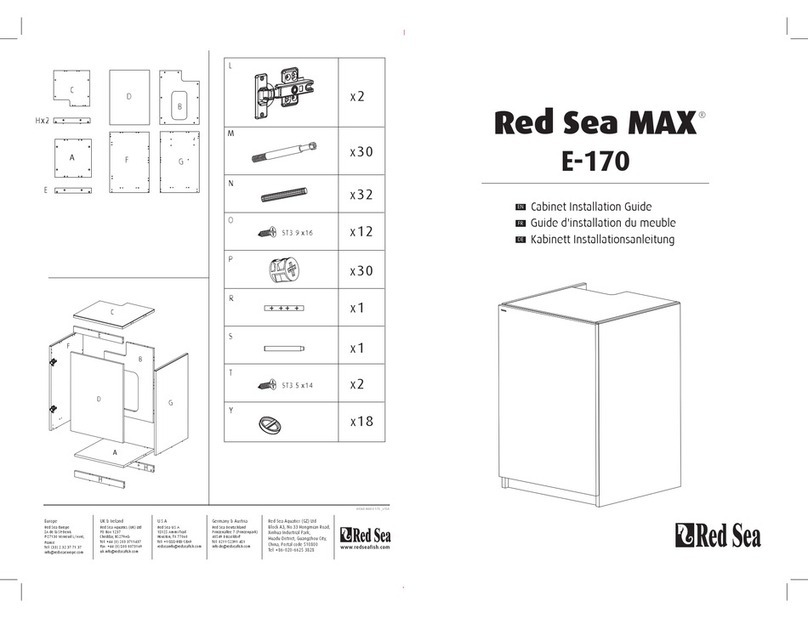

Cabinet assembly

WARNING: If you are not experienced in the construction of self assembly furniture, seek suitably qualified

assistance�

The parts of the frame are connected by screwing self-tapping screws through the corner brackets into pre-

drilled holes in the aluminum profiles. This is best achieved by using a power drill with an adjustable torque. It is

necessary to apply pressure when screwing self tapping screws into aluminum. To ensure that all screws of the

frame are properly seated the manual shows turning the frame around during the various stages of assembly so

that pressure can easily be applied by screwing downwards while the parts are supported by the floor.

When screwing into plastic parts such as the aquarium base board or the lower front plinth, use a hand

screwdriver and not the power driver.

NOTE: The upper and lower plinths are part of the color trim pack.

The adjustable feet on the bottom of the cabinet enable the system to be leveled irrespective of the flatness of

the floor. When assembled the height of the feet can be adjusted so that the bottom edge of the side panels will

be 6–12mm (1/4” – ½”) above the floor. Initially assemble the 4 corner feet to the highest position and all other

feet to be touching the stainless steel foot plates.

Placing Aquarium

Before placing the aquarium in its operating position familiarize yourself with top-up reservoir outlet, main pump

and down pipe connections and the flow control valve that are located at the back right corner of the aquarium.

Once the system is in its operating position approximately 15cm (6”) from the wall, the valve and connectors are

accessible from the side.

WARNING: Lifting the glass aquarium onto

the cabinet will require at least 4 people.

The top of the cabinet is approximately

92cm / 36” from the floor. The table

shows the approximate weights of the

different models of MAX®S aquarium.

Ensure that anyone lifting the aquarium is

physically suitable for such an operation

and has been instructed in the correct

methods of lifting heavy objects.

Aquarium must be lifted from the bottom.

Take care not to damage the plastic rim on the front and sides at the top and bottom of the glass. Some damage

to the rim will not affect the assembling of the external color trim.

Before lifting aquarium, place the assembled cabinet in the final operating position (see location above) and set

the glass aquarium in position on top.

The back of the glass should be flush with the rear edge of the cabinet top board. The front and sides of the glass

should protrude slightly beyond the edges of the cabinet board such that the protrusion is approximately even on

both sides. Incorrect positioning of the aquarium on the cabinet will interfere with the assembly of the color trim.

Once the aquarium is correctly aligned with the cabinet, check that the cabinet has not moved. If necessary

readjust the position of the cabinet.

Approximate weights of Aquarium Glass

Model Metric (kg) Imperial (lb)

S-400 100 220

S-500 120 265

S-650 140 310