2 Special references

2.1 Instructions

The following standard is applicable to fastener driving tools; EN792-13:2000‖Hand-held non-electric power tools-safety

requirements –Part 13: Fastener driving tools‖.

This standard requires that

-Only those fasteners which are specified in the operating instructions (see TECHNICAL DATA) shall be used in

fastener driving tools. The fastener driving tool and the fasteners specified in the operating instructions are to be

considered as one unit safety system;

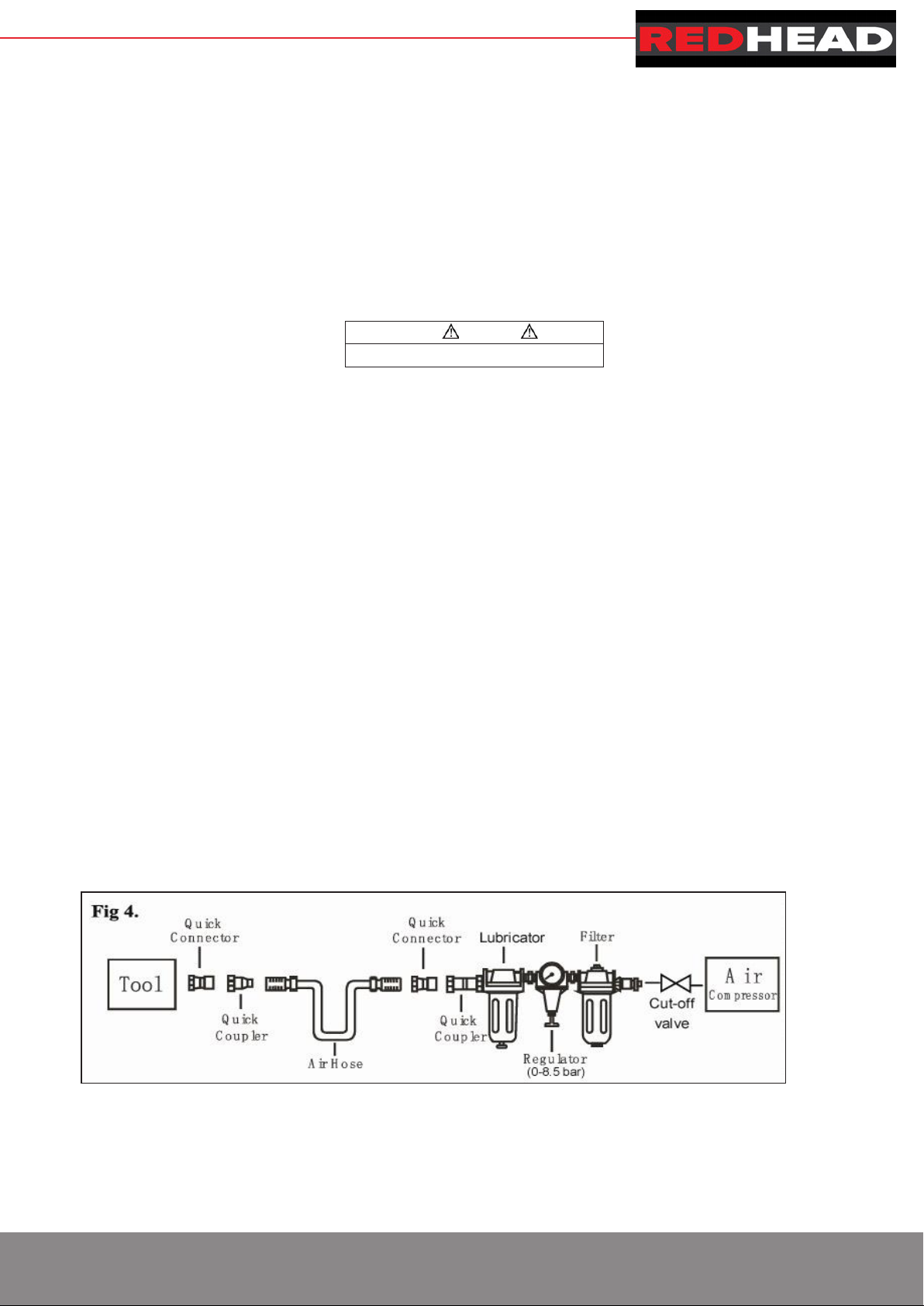

-quick action couplings shall be used for connection to the compressed air system and the non-sealable nipple

must be fitted at the tool in such a way that no compressed air remains in the tool after disconnection;

-oxygen or combustible gases shall not be used as an energy source for compressed air operated fastener driving

tools;

-fastener driving tools shall only be connected to an air-supply where the maximum allowable pressure of the tool

cannot be exceeded by more than 10%;in the case of higher pressure ,a pressure reducing valve which includes a

downstream safety valve shall be built into the compressed air supply;

-only spare parts specified by the manufacturer or his authorized representative shall be used in the repair of

fastener driving tools;

-repairs shall be carried out only by the manufacturers authorized agents or by other experts, having due regard to

the information given in the operating instructions.

-stands for mounting the fastener driving tools to a support, for example to a work table, shall be designed and

constructed by the stand manufacturer in such a way that the fastener driving tools can be safely fixed for the

intended use, thus for example avoiding damage, distortion, displacement.

Special fields of application for the fastener driving tool may require the observance of additional provisions and

regulations.

-only the main energy and lubricants listed in the operating instructions may be used:

-fastener driving tools marked with an inverted equilateral triangle standing on one point may only be used with an

effective safety yoke;

-for the maintenance of fastener driving tools, only spare parts specified by the manufacturer or his authorized

representative shall be used;

-repairs shall be carried out only by agents authorized by the manufacturer or by other specialists, having due

regard to the information given in the operating instructions;

-NOTE: Specialists are those who, as a result by professional training or experience, have sufficient expertise

in the field of fastener driving tools and sufficient familiarity with relevant govemmental industrial protection

provisions, accident prevention regulations, directives and generally recognized technical

regulations(e.g.CEN-and CENELEC-standards),to be able to assess the safe working condition of fastener driving

tools.

2.2 Noise emission

The characteristic noise values for the fastener driving tool have been determined in accordance with EN12549:1999 and

EN ISO4871‖Acoustics-Noise test code for fastener driving tools-Engineering method‖(see Technical Data).

These values are tool-related characteristic values and do not represent the noise development at the point of use. Noise

development at the point of use will for example depend on the working environment, the work piece, the work piece

support and the number of driving operations, etc.

Depending in the conditions at the workplace and the form of the workplace, individual noise attenuation measures may

need to be carried out, such as placing work pieces on sound-damping supports, preventing work piece vibration by

means of clamping or covering, adjusting to the minimum air pressure required for the operation involved, etc,

In special cases it is necessary to wear hearing protection equipment.