8

INSTALLATION(continued)

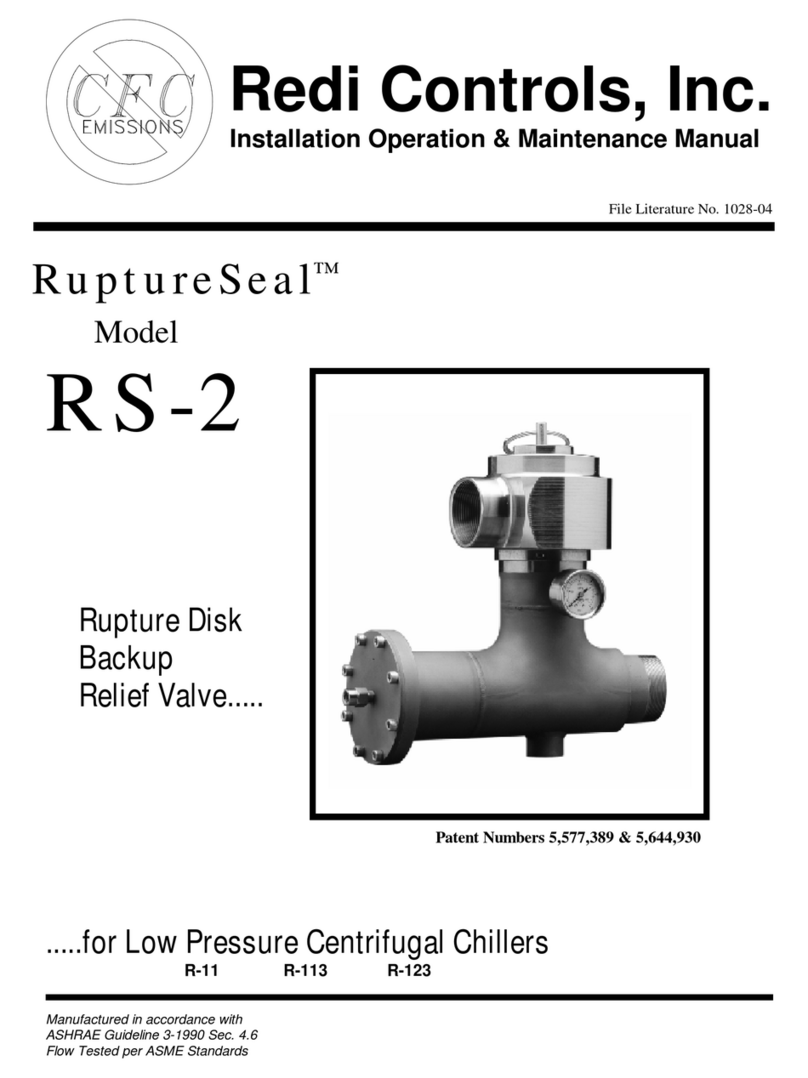

1. Determine thebest mountingarrangement forthe

RuptureSeal™inrelationtothechiller’sexistingrelief

outletandventpiping. Alsodetermineifsupplemental

supportforthevalvewill benecessary(seeFigure7on

page 10).Notethat thevalvebodycan berotated 360°to

orienttheoutlettotheventpipe.Torotatethevalvebody,

loosen(donot remove)thefive(5)valvebodylocking

screws(seeAppendix“C” onpage16forillustrations).

Onceinposition, re-tighten(donotovertighten)thefive(5)

valvebodylockingscrews.(See Figure3onpage9for

location oflockingscrews.)

2The RuptureSeal™“valve”canbe mountedineithera

verticalorhorizontalposition(see Figure1 - Typical

Installation).TheNRS-3cannotbemountedupside

down.

NOTE: Regardless ofNRS-3’smounting position,theDoubleCheck PressureEqualizing Valve (22)

MUST bemountedverticallywiththefilter/vent (34) pointingup(é).

3. Determinehowmuchoftheexistingrupturedisk

ventpipingwill havetobe removed to

accommodatethe RuptureSeal™. Cutoutand

removethissection of piping.

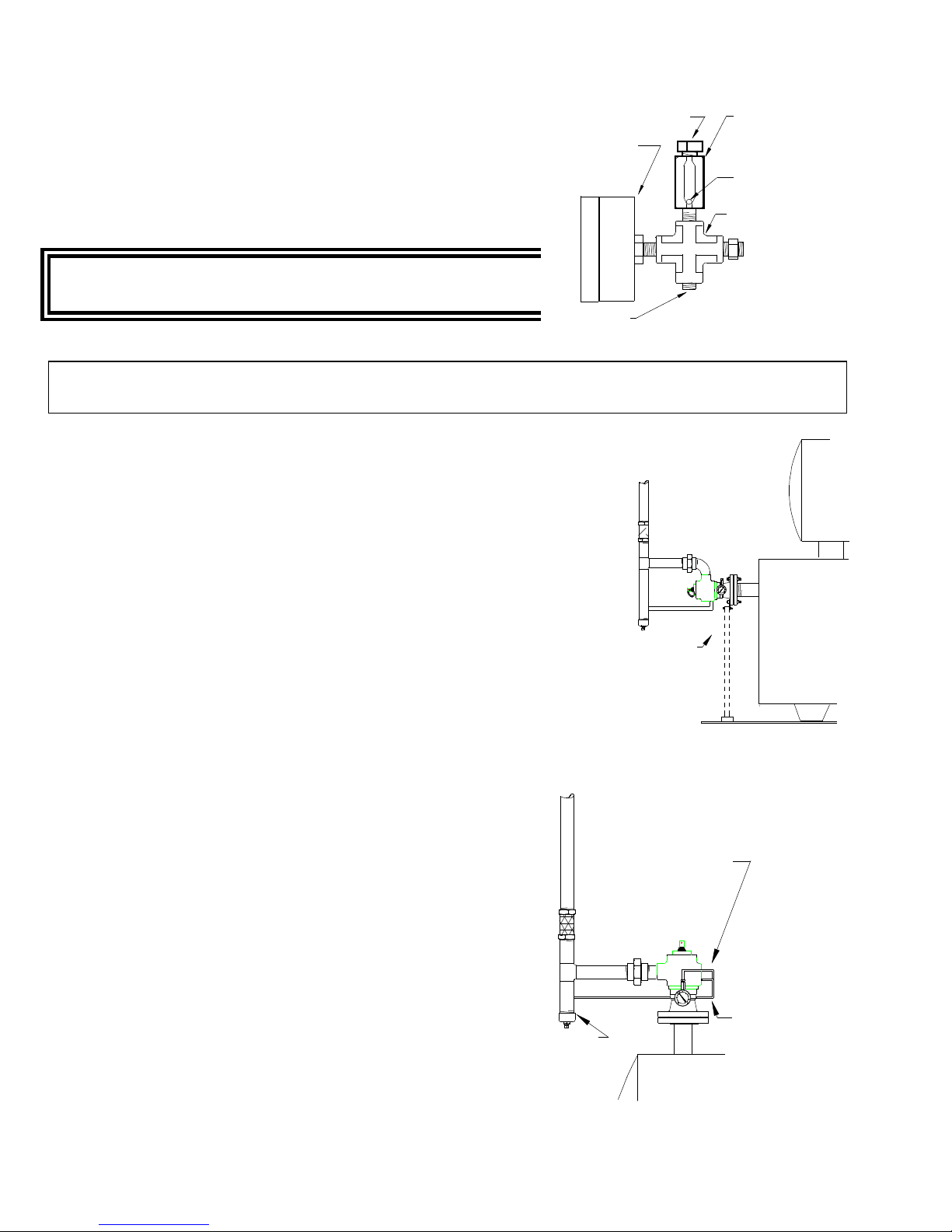

4. It isrecommendedthataflexiblemetal

connection (33) anda3”NPTunion (12) be

installedasillustratedinFigure2.

5. Theinstallershall determine thebestwayto

plumbthedischargevent lineusingfigure2as

apipingguide.

6.Insertthe Flange Gasketbetween the Valve

InletFlange andtheexistingchillerrupturedisk

flange.

7.Usingthefourflangeboltsprovided,mountthe

valvetothe chillerrupturedisk flange.Tighten

boltssufficientlytoassureproperleakfreeseal.

Chiller

Figure 1

Typical Installation

(SeeAppendix“C”for otherillustrations)

(11) VentPipe

(33) Flexible

Metal

Connection

(37 Water

drain

hole

connection

to drip leg

Chiller

(31)

Drip

Leg

(12) 3" NPT

Union (24) Valve

Body

water

drain

hole

Figure 2.

Vent Pipe Hook-up