5

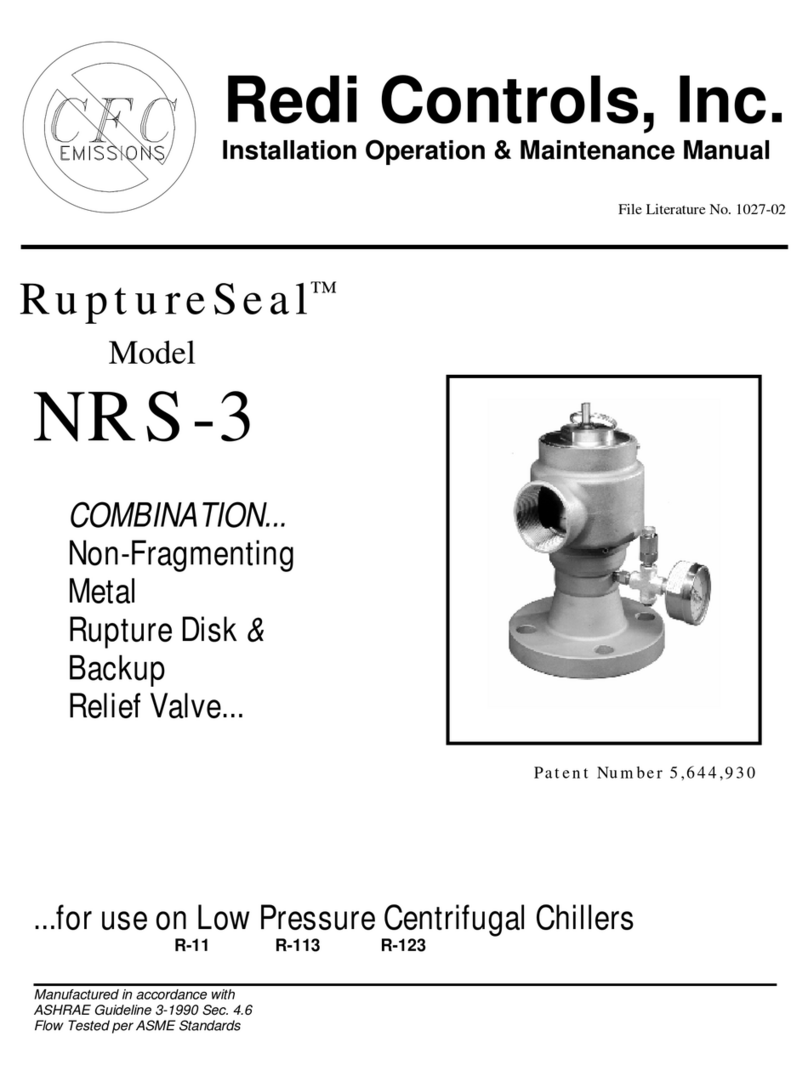

Specifications

Flowcapacity:940 SCFM

Setpressure:15 psig

Reseals“bubbletight”within 3psiofset

pressure

Refrigerantcompatibility:R-11

R-113 &R-123

Weight:17 pounds

Dimensions(approximate):Length13

inches;height13 inches;width6inches

Inlet - 2-inchmaleNPTpipethreads

Outlet - 2-inchfemaleNPTpipethreads

IntegralsupportBoss - 3/4-inchpipe

O-Ring seat - sealsbubbletight

VALVE CONSTRUCTEDOFSTAINLESS

STEEL

Tell-talepressuregauge 30”Hg -0- 30 psig

Doublecheck pressureequalizing valve

(included)

Everyvalve100%testedfor pressure

setting and leakage

O-Ringsserviceablewithoutdisturbing

pressurereliefcalibration

Carbon fragmentcollection trapwith

speciallyformulatednon-toxic, non-

corrosivetack compound

Directspring acting

Pivotedspring action correctsmis-

alignmentand compensatesfor spring

sidethrust

Calibration isfactorysealedtoprevent

inadvertenttampering or dis-assembly

High capacityfull nozzledesign

Instantaneous“pop open” action

BACK PRESSURE COMPENSATED

General Overview

The RuptureSeal™rupturedisk backup reliefvalve, withits exclusivecarbon fragment collection trap,

isdesigned specificallyforinstallation inserieswithexisting carbon type fragmenting rupturedisks

used on lowpressure(15 psiorbelow) centrifugalchillers.

The primaryfunction ofthe RuptureSeal™isto minimizerefrigerantloss tothe atmosphereinthe

eventofaburstrupturedisk.The RuptureSeal™accomplishesthisvitalfunction byautomatically

closing off the ventpath,thusre-sealing the chilleroncepressurereturnstonormal.Inthe eventof a

burst rupturedisk, the RuptureSeal™alsoservesasthe interim primaryrelief.

NOTE: The RuptureSeal™ modelnumberdesignatesthe sizeofcarbon fragmenting rupturedisk it is

designed tobe used with(i.e., the “RS-2”isdesigned tobe used withatwo (2”) inchcarbon

fragmenting rupturedisk designed forcentrifugalchillers)..TheRS-2hasaflowcapacityof940

SCFM,however(perASHRAEguidelines),thiscapacitymustbede-rated10%wheninstalledin

serieswitharupturedisk.Whenfitting theRS-2 toachiller,theinstallermustdetermineifthe

de-ratedflowcapacityisadequatefor thatchiller.INCLUDEDFORYOURCONVENIENCEAS

Appendix“A”ISATABLEOFVARIOUSVESSELDIMENSIONSCOVEREDBYTHEMODELRS-2

RuptureSeal™ AFTER10%DE-RATING based on computationsusing the formulaprovided bythe

Guideline BSR/ASHRAE 15-1992R. Appendix“B”ofthismanualcontainsthe excerptfromthe

Guideline BSR/ASHRAE 15-1992Rwhich can be used todetermine the minimumflowcapacity

requirement forapressure-relief deviceasapplied toalowpressurecentrifugalchiller.