4

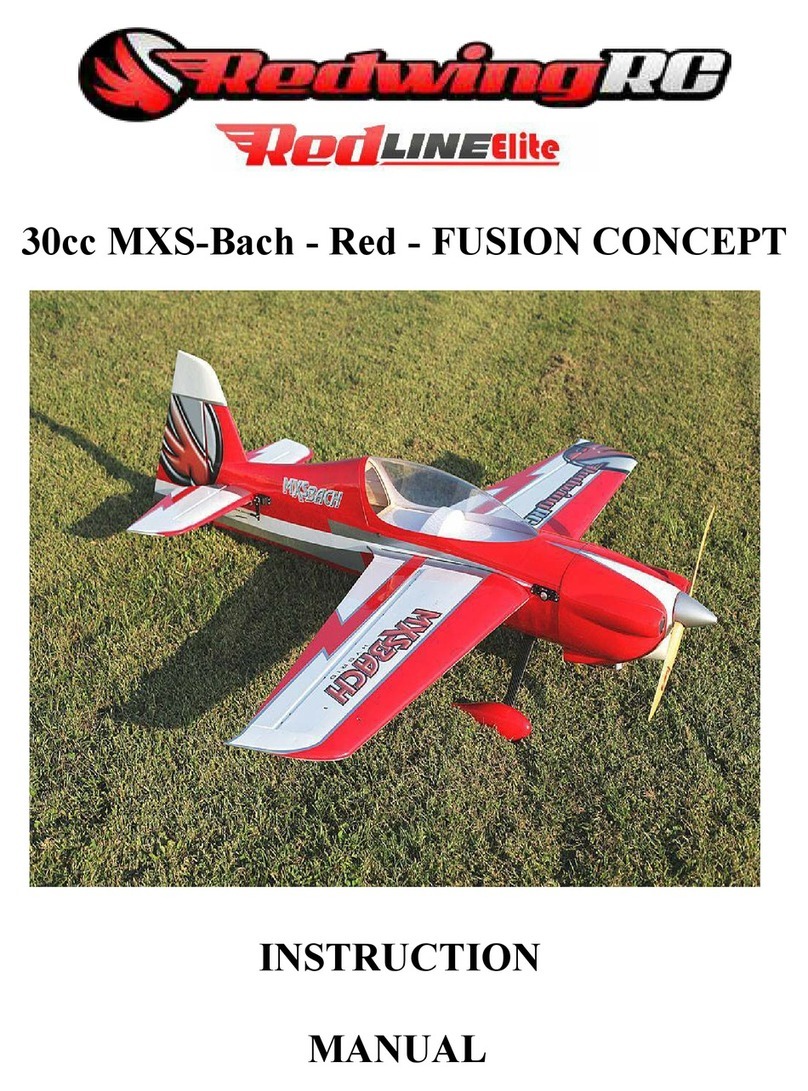

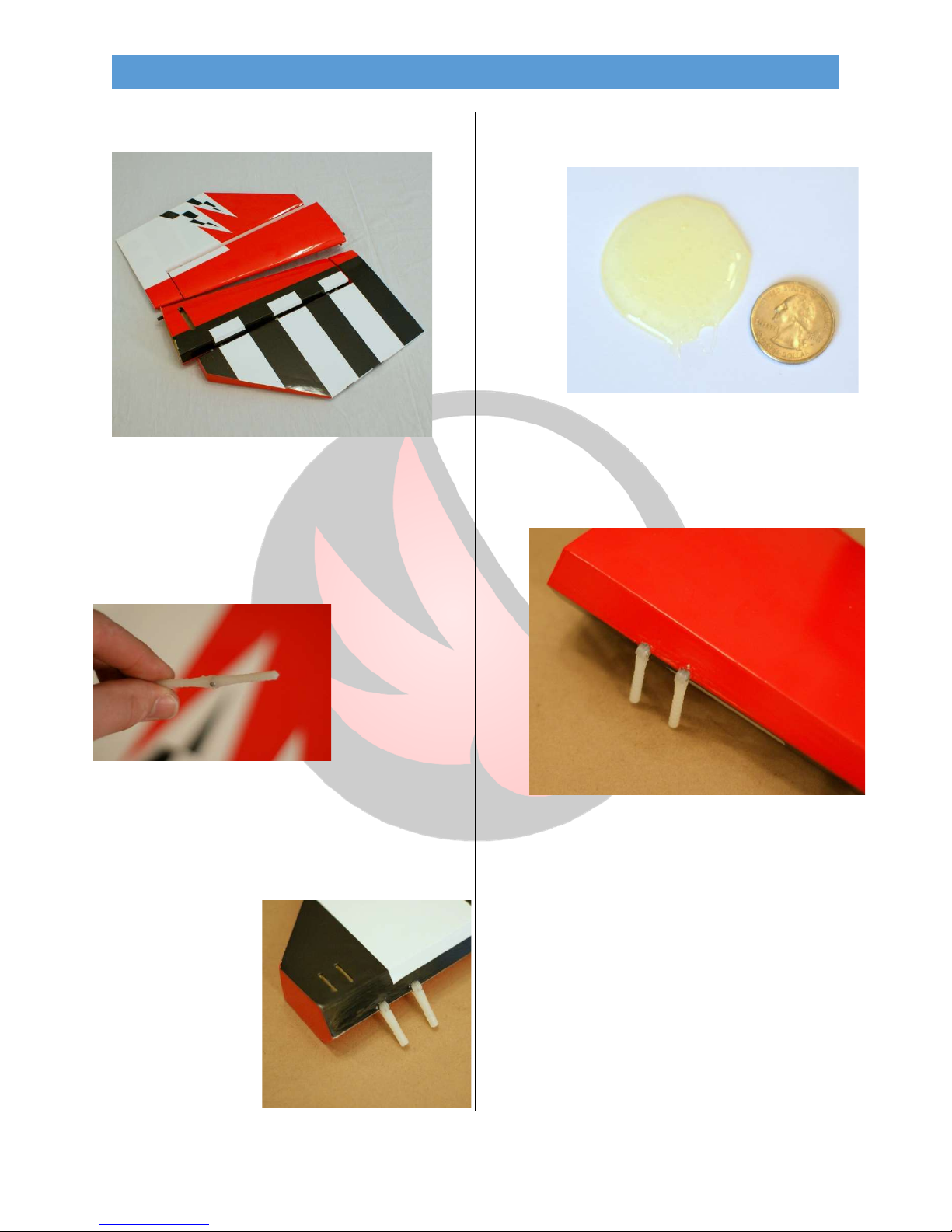

•Using the linkage hardware, join the two horns

as shown. Then mix a small batch of 15 min

epoxy and coat the inside of the slots. Lightly

coat the ends of the control horns and insert

them into the slots, angled toward the hinge

line as shown.

•You should have minimal squeeze out and a

small fillet will form at the base of the horns.

Clean up any excess with denatured alcohol.

•Once the control horn has cured determine

the method for mounting the servos you wish

to use.

Option A: Surface mount

Option B: Hatch mount

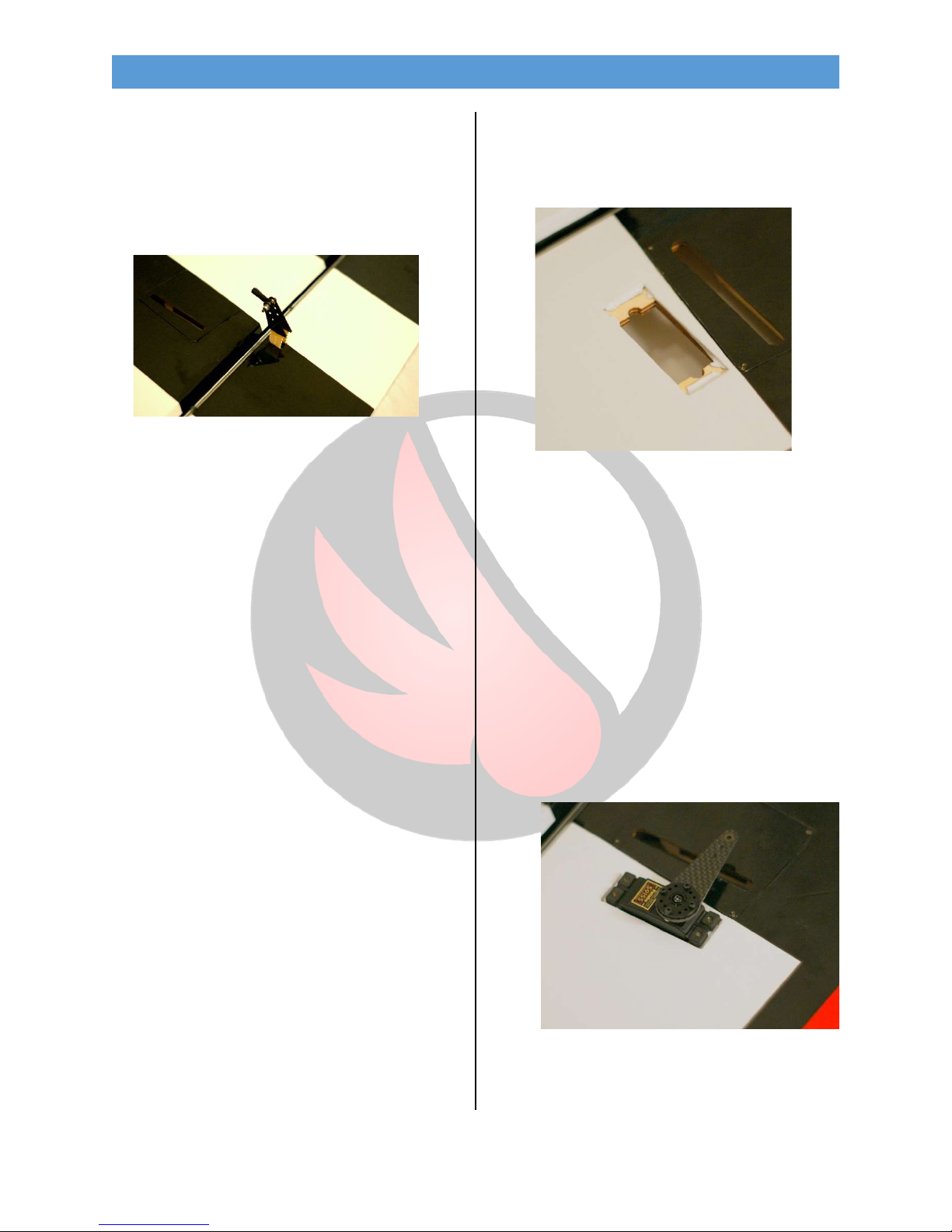

Aileron Servo OPTION A

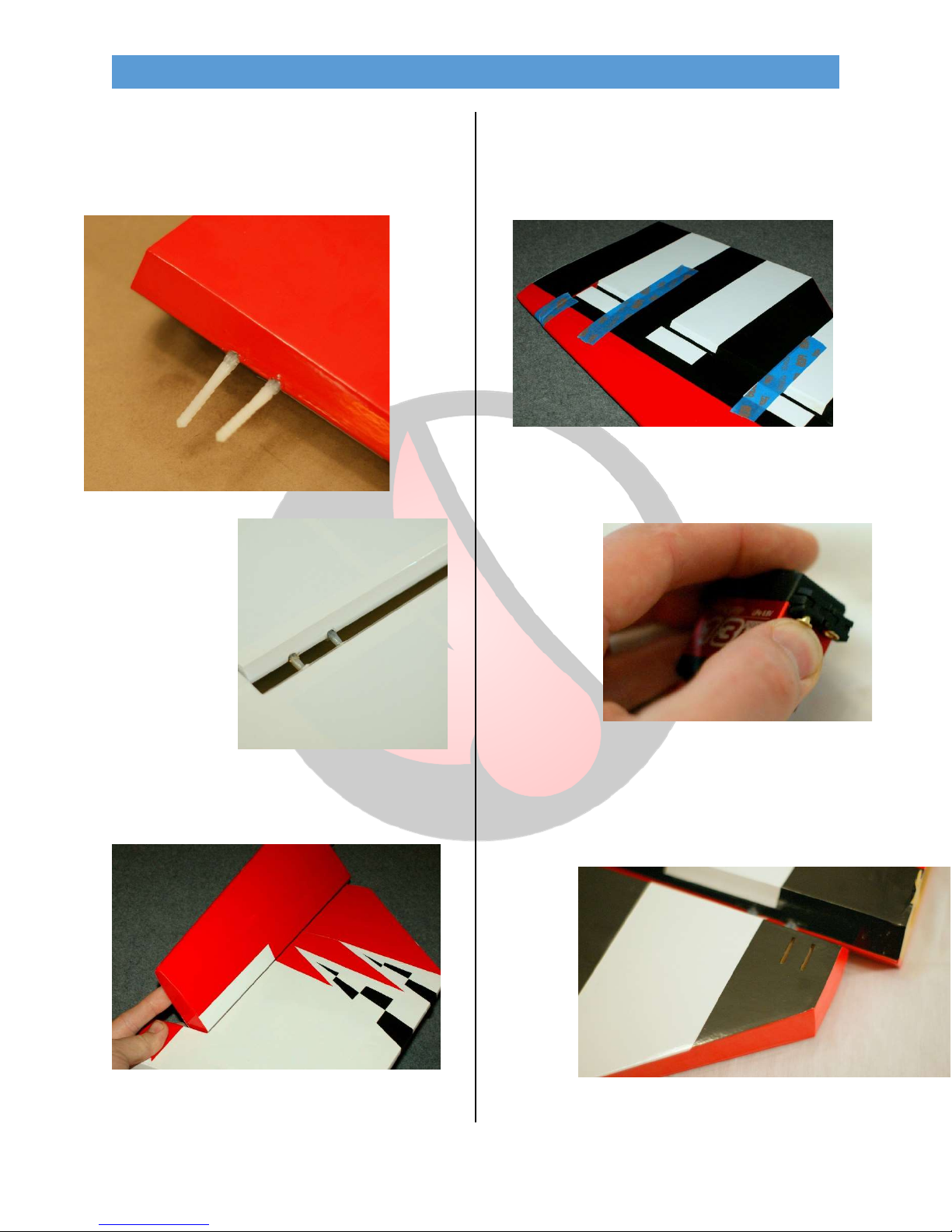

•Locate the servo pocket and remove the

covering. Then drop the servo into place and

drill for the servo screws with a 1/16” drill bit.

From the Pro: When removing the covering leave

1/8-1/4” of covering to be ironed down into the

servo pocket. This makes for a much cleaner and

more fuel-proof servo cut-out.

•Remove the servo and thread a servo screw in

and out of each hole. Then apply 2 drops of thin

CA to each and allow the CA to soak in and fully

cure.

•Install the servo with the output to the leading

edge, pulling the wire lead out to the root of

the wing. Center the servo and install the servo

horn pointing toward the wingtip, aligning with

the control horn.