3

1117-55301

launaMs’rotarepOevirDrewoPDP1035

7. Use only three-wire extension cords which have three-

prong grounding plugs and three-pole receptacles which

accept the tool’s plug. Use of other extension cords will

not ground the tool and increase the risk of electrical

shock.

8. Use proper extension cords (see Chart). Insufficient

conductor size will cause excessive overheating.

9. Keep all extension cord connections dry and off the

ground. Do not touch plugs or tool with wet hands.

Reduces the risk of electrical shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use com-

mon sense when operating a tool. Do not use tool

while tired or under the influence of drugs, alcohol, or

medications. A moment of inattention while operating

power tools may result in serious personal injury.

2. Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep hair, clothing, and

gloves away from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

3. Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch on

invites accidents.

4. Do not overreach. Keep proper footing and balance at

all times. Proper footing and balance enables better con-

trol of the tool in unexpected situations.

5. Use safety equipment. Always

wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or

hearing protection must be used for

appropriate conditions.

6. Operate machine from side with REV/OFF/FOR

switch.

GENERAL SAFETY INFORMATION

WARNING: READ AND UNDERSTAND ALL INSTRUC-

TIONS. FAILURE TO FOLLOW ALL INSTRUCTIONS

LISTED MAY RESULT IN ELECTRIC SHOCK, FIRE, AND/

OR SERIOUS PERSONAL INJURY.

SAVE THESE INSTRUCTIONS!

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered benches

and dark areas invite accidents.

2. Do not operate tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Tools create sparks which may ignite the dust or fumes.

3. Keep by-standers, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

4. Do not let visitors contact the tool or extension cord.

Such preventative measures reduce the risk of injury.

ELECTRICAL SAFETY

1. Grounded tools must be plugged into an outlet, prop-

erly installed and grounded in accordance with all

codes and ordinances. Never remove the grounding

plug or modify the plug in any way. Do not use adapter

plugs. Check with a qualified electrician if you are in doubt

as to whether the outlet is properly grounded. If the tool

should electrically malfunction or break down, grounding

provides a low resistance path to carry electricity away

from the user.

2. Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an

increased risk of electrical shock if your body is grounded.

3. Do not expose electrical parts to rain or wet condi-

tions. Water entering a tool will increase the risk of elec-

trical shock.

4. Do not abuse cord. Never use the cord to carry the

tools or pull the plug from the outlet. Keep cord away

from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase

the risk of electrical shock.

5. When operating a tool outside, use an outdoor exten-

sion cord marked “W-A” Or “W”. These cords are rated

for outdoor use and reduce the risk of electrical shock.

6. Connect the tool to an AC power supply that matches

the name plate specification. Incorrect voltage supply

can cause electrical shock or burns.

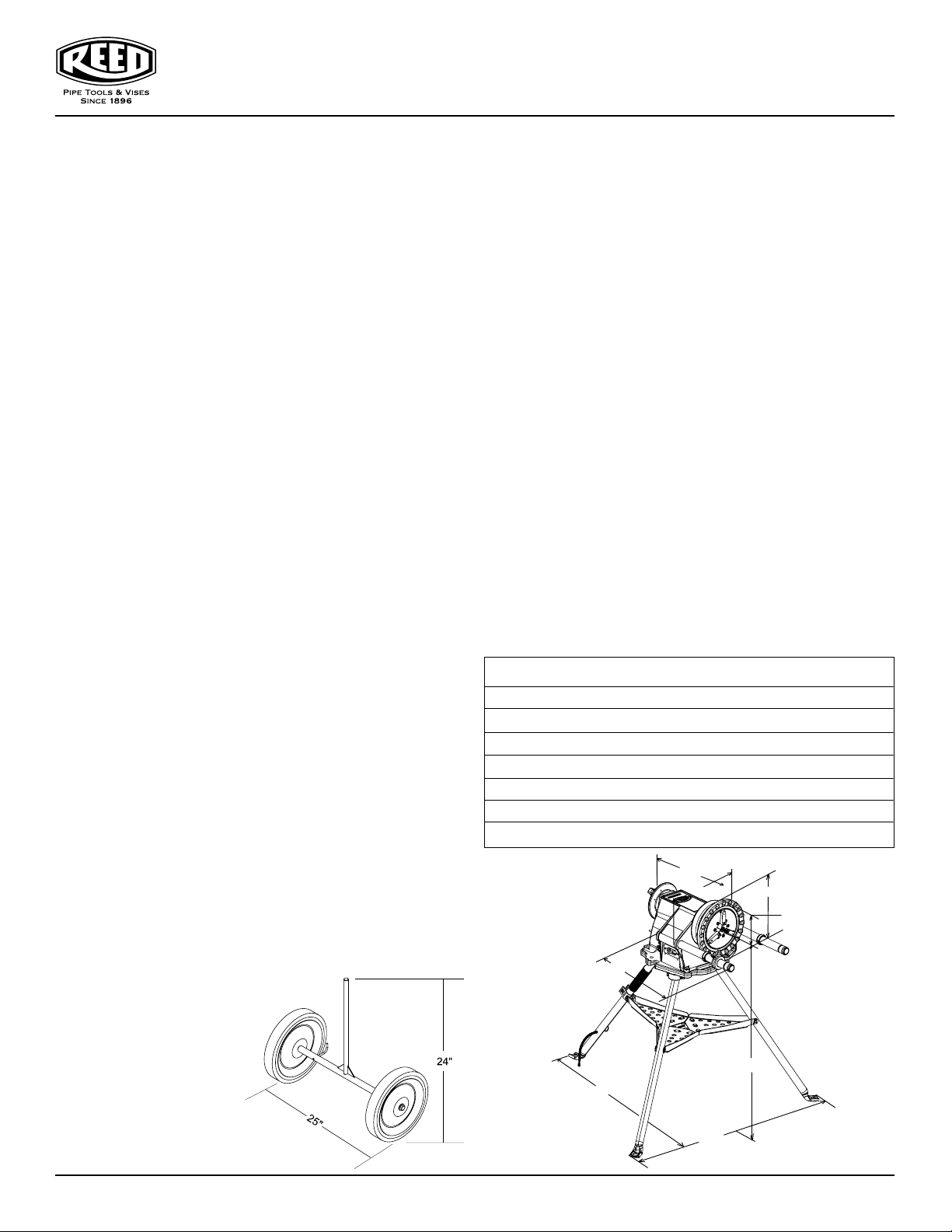

Minimum Wire Gauge for Cord Set

Nameplate TOTAL LENGTH (IN FEET)

Amps 0 - 25 26 - 50 51 - 100

0 - 6 18 AWG 16 AWG 16 AWG

6 -10 18 AWG 16 AWG 14 AWG

10 - 12 16 AWG 16 AWG 14 AWG

12 - 16 14 AWG 12 AWG

NOT

RECOMMENDED